A production device and method for enhanced salt removal and desulfurization of high-sulfur seed separation mother liquor

A production device and mother liquor separation technology, applied in the field of alumina production by Bayer process, can solve the problems of unsatisfactory desulfurization effect, complicated process and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

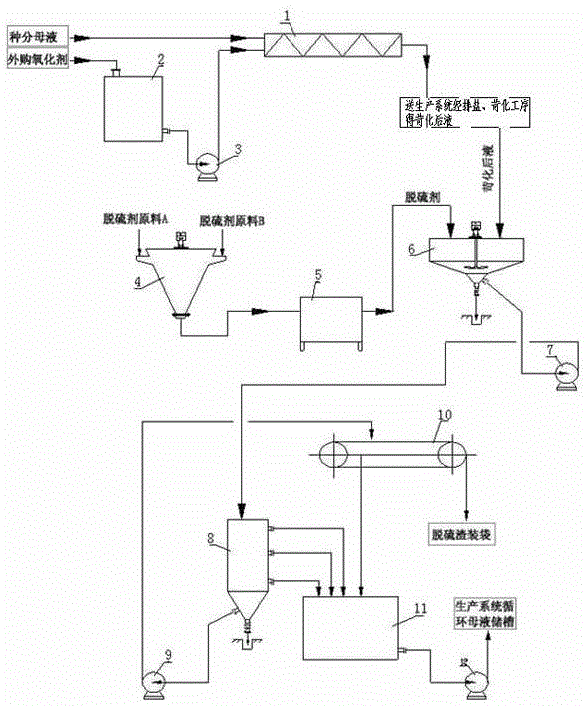

[0016] Embodiments of the present invention: as figure 1 As shown, the inlet of the static mixer 1 is connected with a mother liquid pipeline and an oxidant pipeline, wherein the oxidant pipeline comes from the oxidant pump 3 and the oxidant storage tank 2 connected thereto; the outlet of the static mixer 1 is connected with the original normal production flow equipment The causticized liquid pipeline and the desulfurizing agent pipeline of the original normal production process equipment are connected with the reaction tank 6, wherein the desulfurizing agent pipeline comes from the electric furnace 5 and the solid mixer 4 connected thereto; the reaction tank 6 is connected with the slurry pump 7, and the slurry pump 7 is connected with the settling tank 8, the underflow outlet of the settling tank 8 is connected with the filter 10 through the underflow pump 9, the overflow pipe of the settling tank 8 and the filtrate pipeline of the filter 10 are connected with the mixed liqui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com