Fiber-reinforced polyvinyl chloride composite floor and its production process

A polyvinyl chloride, fiber-reinforced technology, applied in the field of foam co-extrusion production technology, can solve the problems of inability to process pressed veneer floors, deformation of plastic floors, increased floor weight, etc., to solve the problems of thermal stability and light stability, The effect of improving stability and improving cost performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

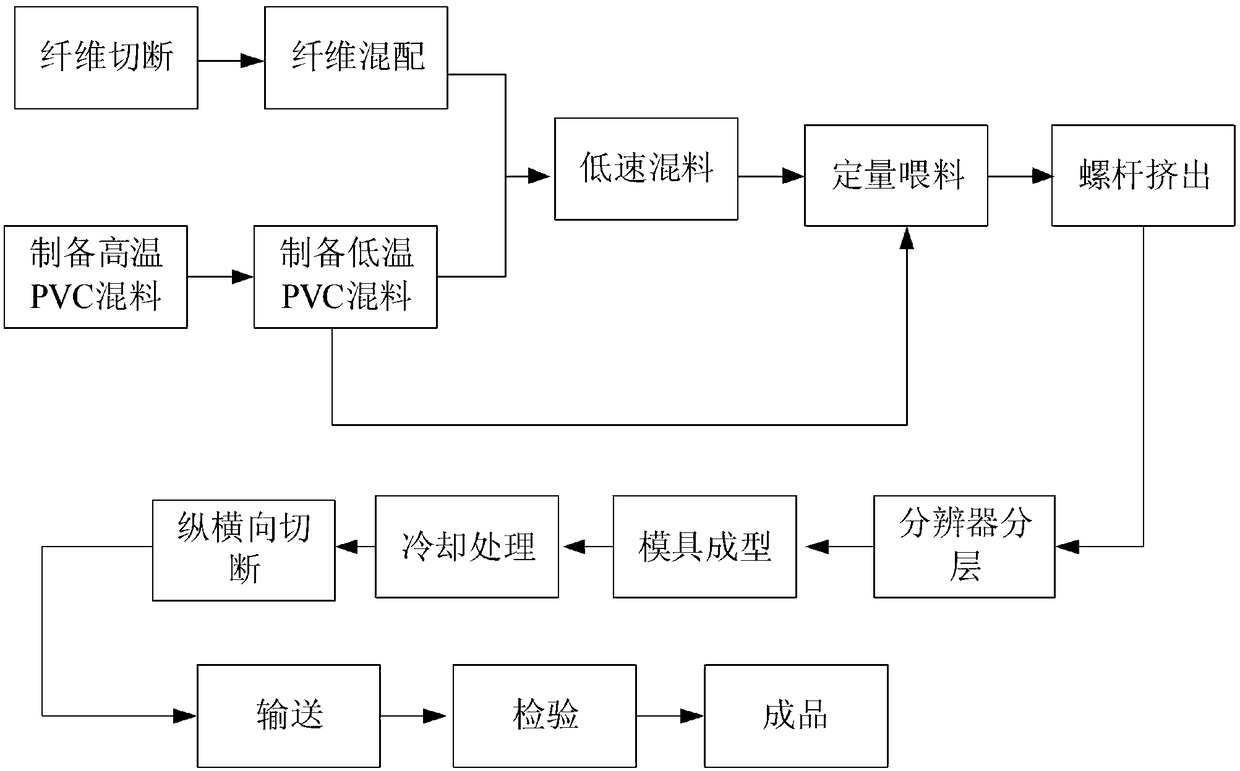

Method used

Image

Examples

Embodiment Construction

[0050] The present invention proposes a fiber-reinforced polyvinyl chloride composite floor. The composite floor has a three-layer structure, including a middle layer and a first outer layer and a second outer layer arranged on both sides of the middle layer. The middle layer is polyvinyl chloride vinyl layer; the first outer layer and the second outer layer are fiber reinforced polyvinyl chloride material layers,

[0051] The raw material of the fiber reinforced polyvinyl chloride material includes the following components by weight percentage: 5%-10% of carbon fiber and 90%-95% of PVC powder.

[0052] A fiber-reinforced polyvinyl chloride composite floor, characterized in that: the composite floor has a three-layer structure, including a middle layer and a first outer layer and a second outer layer arranged on both sides of the middle layer, and the middle layer is polyvinyl chloride vinyl layer; the first outer layer and the second outer layer are fiber reinforced polyvinyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com