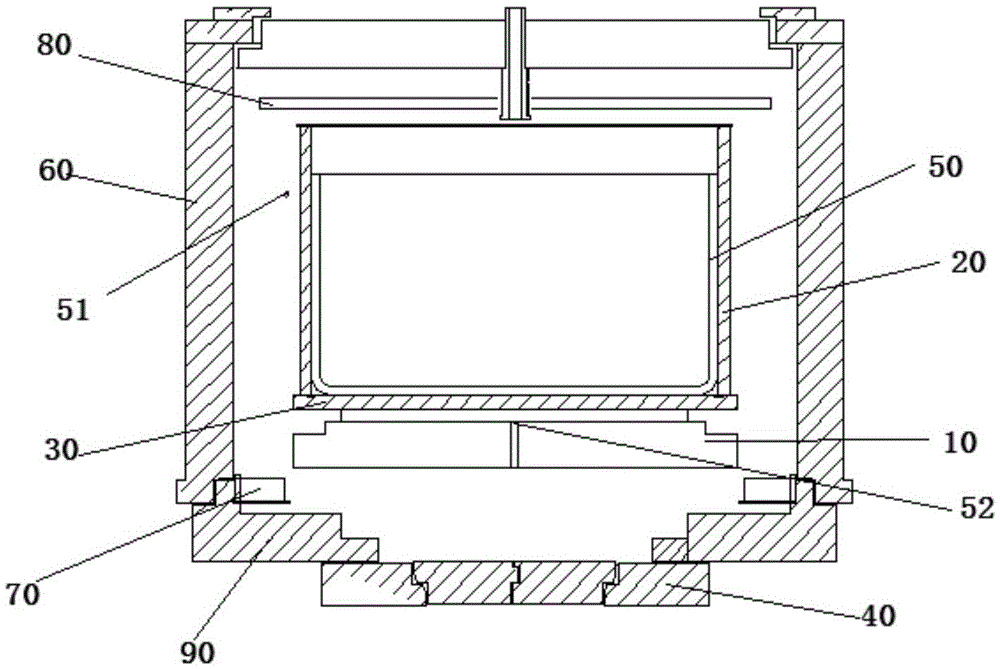

Ingot casting furnace and method for controlling seed crystal retention height during quasi-single crystal casting

An ingot furnace and control technology, which is applied in the field of monocrystalline silicon-like manufacturing, can solve problems such as difficulties and the large surplus of seed crystals, and achieve the effect of improving the success rate of casting and ensuring the remaining amount of seed crystals.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

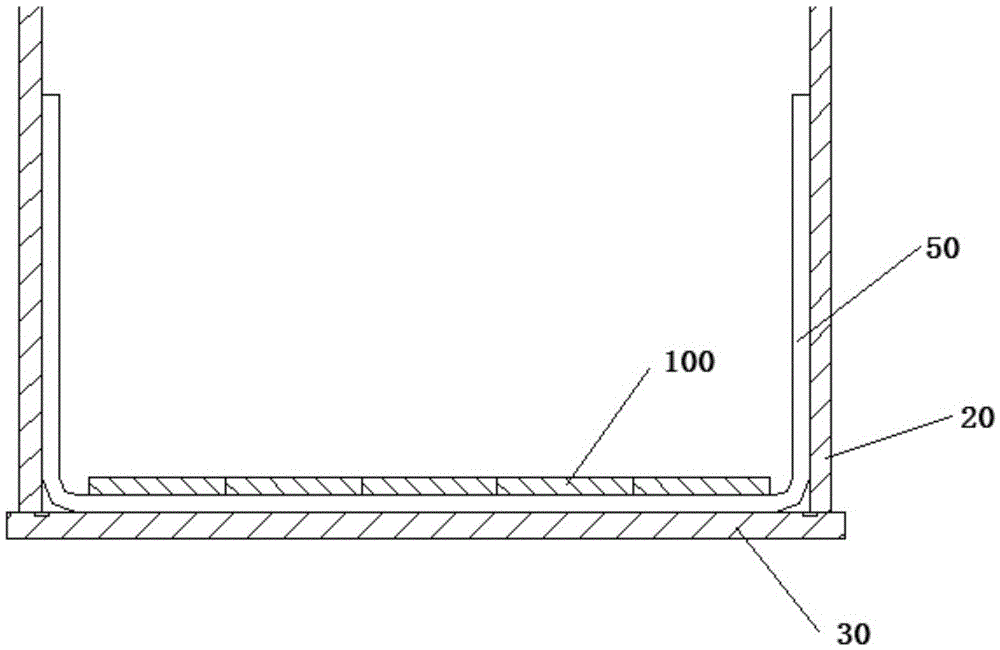

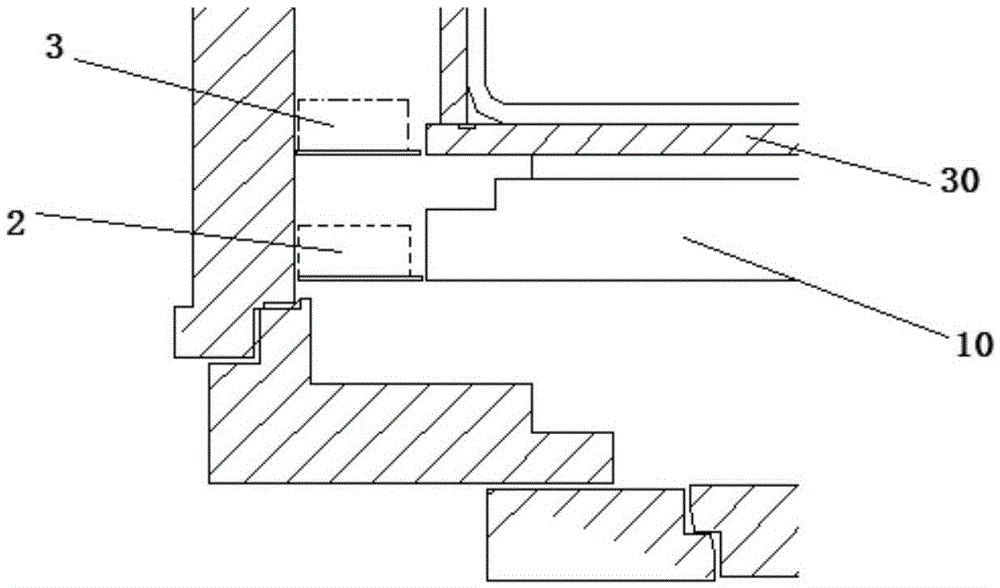

Method used

Image

Examples

Embodiment approach

[0036] According to a typical implementation of the present invention, the method includes the following steps: Step 1: maintain the temperature at the top temperature measuring point 51 at 1135°C to 1175°C, the shutters 40 are closed, and the position of the heat insulation baffle 70 is the original position. position, the time is 60 to 120 minutes; in the second step, the temperature at the top temperature measuring point 51 rises to 1480°C to 1510°C, the shutter 40 is closed, and the position of the heat insulation baffle 70 is the original position, and the time is 180 to 300 minutes; In the third step, within 30 to 60 minutes, the temperature of the top temperature measuring point 51 rises to 1520°C to 1550°C, and the position of the heat insulation baffle 70 rises by 3 to 7 cm; the fourth step: maintain the final state of the third step unchanged 270 ~330 minutes; the fifth step: within 30~60 minutes, the temperature of the top temperature measuring point 51 drops to 1495...

Embodiment 1

[0042] The first step: maintain the temperature at the top temperature measuring point 51 at 1175°C, the louvers 40 are closed, and the position of the heat insulation baffle 70 is the original position, and the time is 60 minutes;

[0043] In the second step, the temperature at the top temperature measuring point 51 rises rapidly to 1480°C, the shutters 40 are closed, and the position of the heat insulation baffle 70 remains unchanged from the original position, and the time is 180 minutes;

[0044] In the third step, within 30 minutes, the temperature at the top temperature measurement point 51 rises from the final temperature of the second step temperature measurement point to 1520°C, and the position of the heat insulation baffle 70 rises by 3 cm;

[0045] Step 4: Keep the final state of the third step unchanged for 270 minutes;

[0046] Step 5: The temperature at the top temperature measuring point 51 is lowered from the final temperature of the third step to 1500°C, and ...

Embodiment 2

[0050] Step 1: Maintain the temperature at the top temperature measuring point 51 at 1135°C, the position of the louvers is closed, and the position of the heat insulation baffle 70 is the original position, and the time is 120 minutes;

[0051] In the second step, the temperature at the top temperature measurement point 51 rises rapidly to 1510°C, the position of the louvers is closed, and the position of the heat insulation baffle 70 remains unchanged from the original position, and the time is 300 minutes;

[0052] In the third step, within 60 minutes, the temperature at the top temperature measurement point 51 rises from the final temperature of the second step temperature measurement point to 1550°C, and the position of the heat insulation baffle 70 rises by 7 cm;

[0053] Step 4: Keep the final state of the third step unchanged for 330 minutes;

[0054] Step 5: The temperature at the top temperature measuring point 51 is lowered from the final temperature of the third pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com