Flexible vertical pipe bending reinforcer with rubber protective sleeve connector

A flexible riser, bending and strengthening technology, used in pipeline protection, pipe/pipe joint/pipe fittings, hose connection devices, etc., can solve the problem of reducing pipeline fatigue life, easy to wear the outer surface of the riser, and high stiffness at the pipeline outlet. problems, to achieve the effect of improving the success rate of casting, simple installation and reducing wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

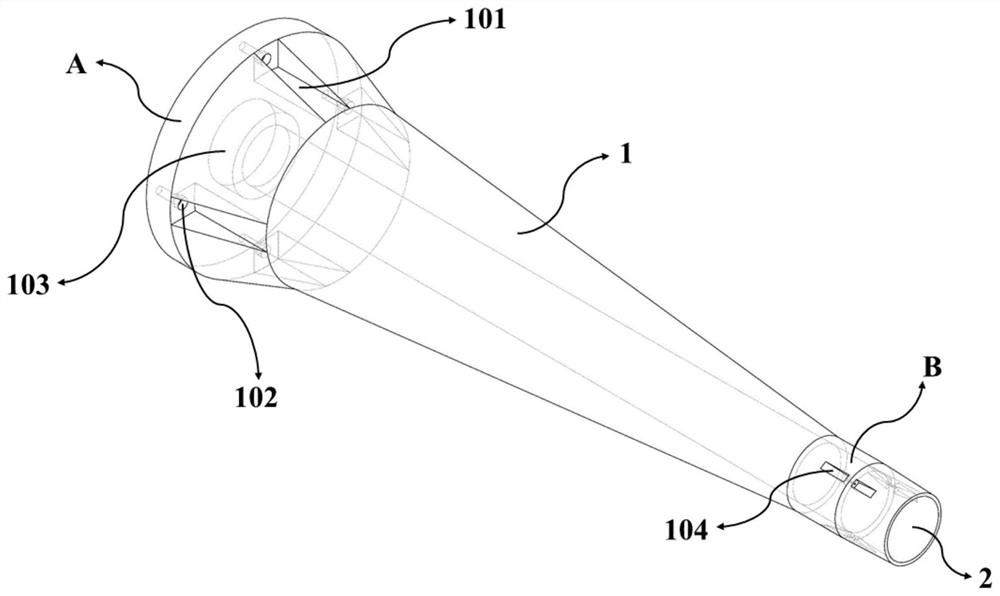

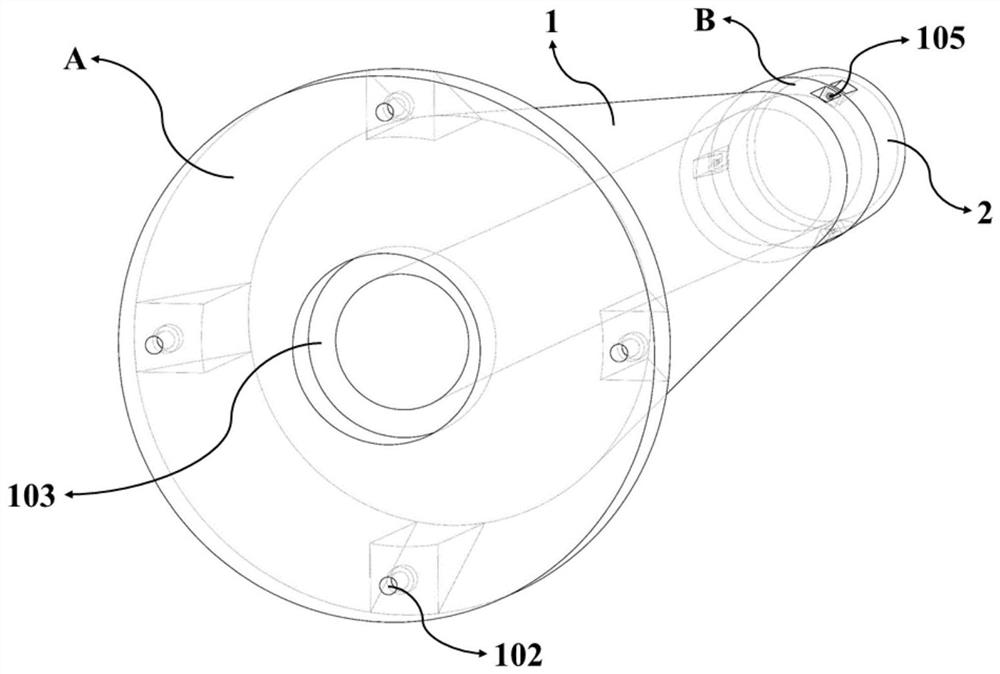

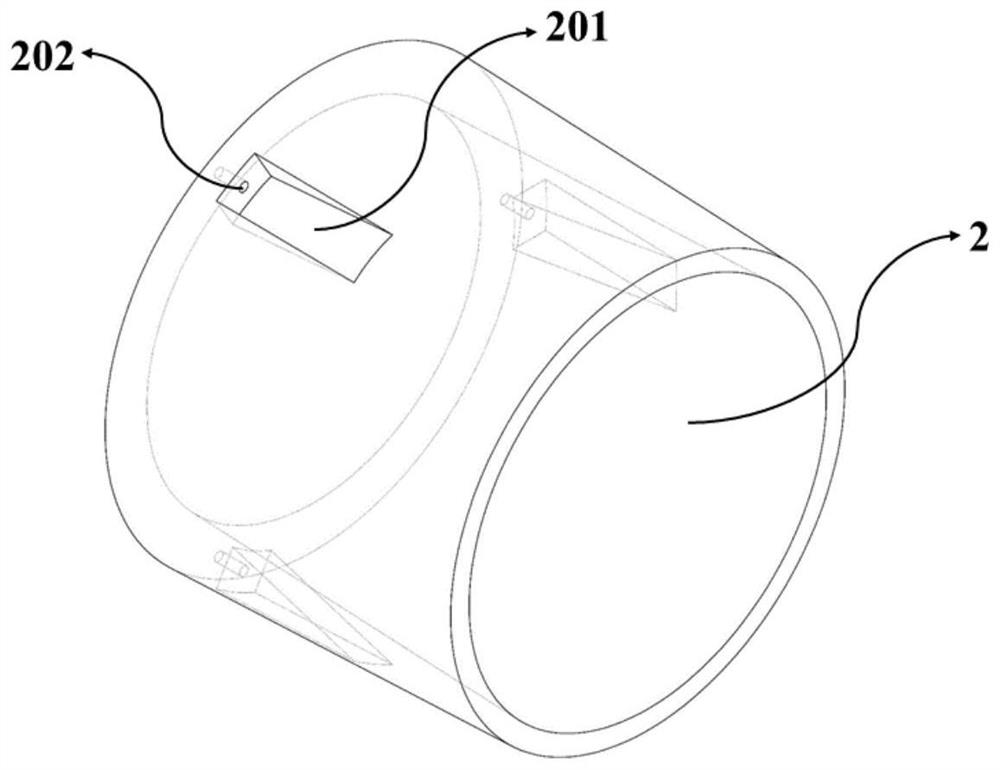

[0019] Such as Figure 1-2 As shown, the deep-sea flexible riser bending strengthener with a rubber protective sleeve interface of the present invention includes a polyurethane three-section main body sleeve 1 and a rubber protective sleeve interface 2 formed by integral casting and fits and wraps the outer wall of the flexible riser. The main body cover 1 is a three-section hollow structure, and the two ends are A end and B end respectively, wherein 104 is a notch on the outer surface of the B end at an interval of 120 degrees, as figure 2 As shown, the notch is provided with a through hole 105, which is convenient for the screw to pass through and connect the rubber protective sleeve interface 2 and the B end with screws. End A of the main body sleeve 1 of the bending stiffener is also evenly distributed with notches 101 at intervals of 90 degrees. A through hole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com