A method for casting aluminum alloy flat ingots of different specifications at one time

A technology of aluminum alloy and aluminum alloy melt, which is applied in the field of aluminum alloy manufacturing, can solve the problems that small orders cannot meet the full furnace production, the impact on production efficiency and economic benefits, and increase the probability of product defects, so as to improve the quality defects of flat ingots, Reduces processing steps and prevents casting cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

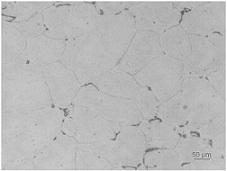

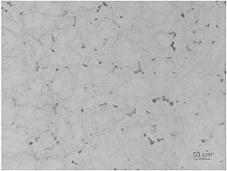

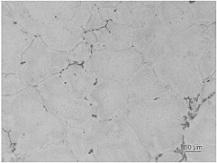

Image

Examples

Embodiment 1

[0030] Hybrid casting of 5083 alloys with specifications of 2570×550 mm and 2270×550 mm:

[0031] (1) Ingredients: Si: 0.02-0.20% by mass percentage, Fe: 0.10-0.35%, Cu: 0.01-0.10%, Mn: 0.50-0.85%, Mg: 4.20-4.80%, Cr: 0.10-0.20% , Zn: 0.01-0.25%, the balance is aluminum, weigh aluminum ingots for remelting, return materials, pure Mg ingots, pure Zn ingots, Al-Si master alloys, Al-Fe master alloys, Al-Cu Master alloy, Al-Mn master alloy, Al-Cr master alloy quality, strictly control the amount of aluminum ingots for remelting with a purity of 99.70% and the amount of 5xxx alloy return material, and the amount of 5xxx alloy return material accounts for 0-60% of the total furnace input ;

[0032] (2) Melting: Put the ingredients into a 55T melting furnace, stir and melt with an electromagnetic stirrer at 690-750°C, after all the alloys are put into the furnace, when the melting temperature reaches 710-740°C, melt again for 5-20 minutes;

[0033] (3) Composition adjustment: Take ...

Embodiment 2

[0042] Mixed casting 1480×520mm, 1780×520, 1400×580 and 1700×580 specifications 3003 alloy:

[0043] (1) Ingredients: Si: 0.02-0.60% by mass percentage, Fe: 0.10-0.40%, Cu: 0.01-0.18%, Mn: 1.10-1.40%, Mg: 0.01-0.04%, Zn: 0.01-0.09% , the balance is aluminum, weigh aluminum ingots for remelting, return materials, pure Mg ingots, pure Zn ingots, Al-Si master alloys, Al-Fe master alloys, Al-Cu master alloys, Al-Mn master alloys Alloy, Al-Cr intermediate alloy quality, precise control of the amount of remelting aluminum ingots with a purity of 99.70% and 3xxx series alloy return materials, the amount of 3xxx series alloy return materials accounts for 0-60% of the total furnace input;

[0044] (2) Melting: Put the ingredients into a 55T melting furnace, stir and melt with an electromagnetic stirrer at 690-750°C, after all the alloys are put into the furnace, when the melting temperature reaches 710-740°C, melt again for 5-20 minutes;

[0045] (3) Composition adjustment: Take the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com