Device and method for relieving negative pressure of long nozzle and impact force of molten steel

A long nozzle and impact force technology, which is applied in the direction of casting molten material containers, metal processing equipment, casting equipment, etc., can solve the problems of large size, high maintenance and operation costs, and achieve the goals of increasing service life, reducing impact force, and slowing down negative pressure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

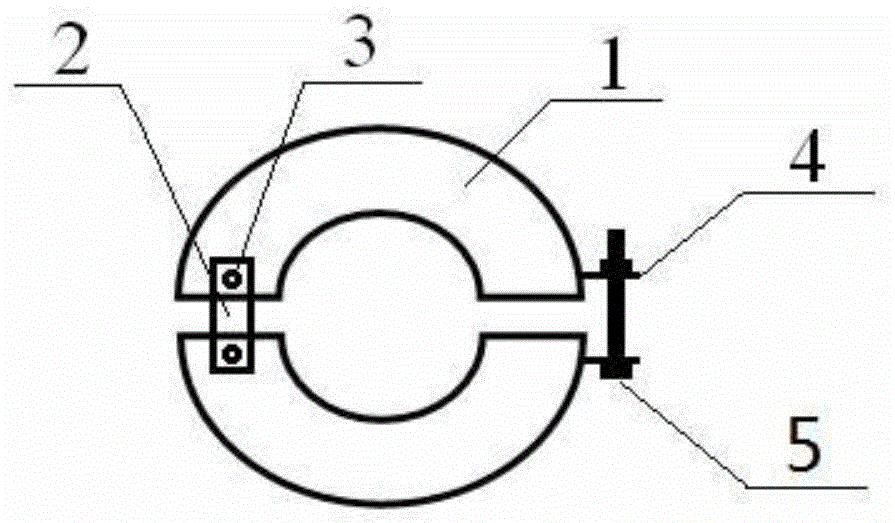

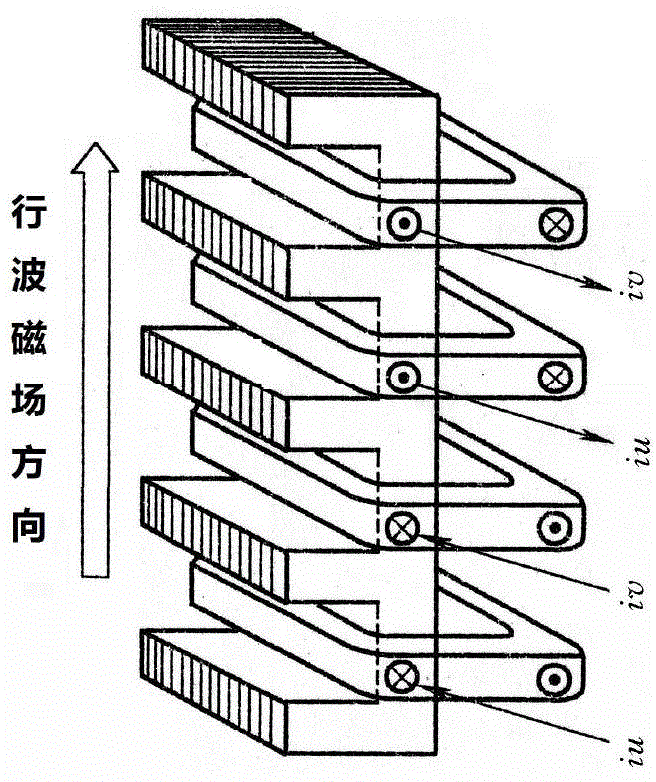

[0023] In the continuous casting process of 230×1060mm slab, the outer diameter of the shroud is Φ155mm, the inner diameter is Φ100mm and the casting speed is 0.8m / min.

[0024] Table 1. Device parameters when the outer diameter of the shroud is Φ155mm

[0025]

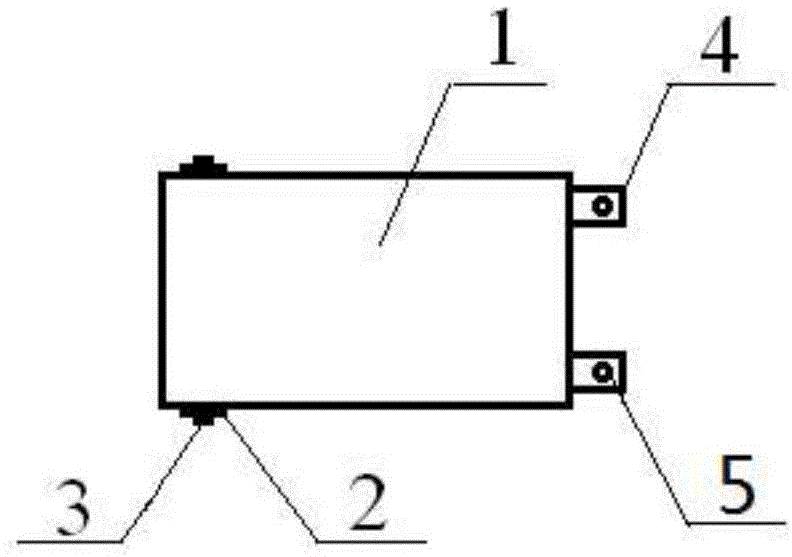

[0026] During use, the housing 1 of the magnetic field generating device is installed on the shroud 7 . Because the device needs to be cooled by water, in order to prevent the temperature from dropping too fast near the long nozzle, it can be protected by refractory felt or other heat-insulating and high-temperature-resistant materials. Set the current size and frequency of the device before starting casting. Turn on the power of the device when casting, and disconnect the power when the casting is over. The cooling water needs to be kept on to ensure that the device will not be burned out. The cooling water of the device can only be disconnected when the ambient temperature is low. Example 2:

Embodiment 2

[0027] In the continuous casting process of 300×1950mm slab, the outer diameter of shroud is Φ195mm, the inner diameter is Φ135mm, and the casting speed is 1.0m / min, the specific parameters of the device designed to slow down the negative pressure of shroud nozzle and the impact force of molten steel are shown in Table 2 .

[0028] Table 2. Device parameters when the outer diameter of the shroud is Φ195mm

[0029]

[0030] The application method is the same as in Example 1. The implementation effect is shown in Table 3. ON indicates the working state of the device, and OFF indicates the closed state of the device. From the experimental results in Table 3, it can be seen that the oxygen content of the tundish does not increase significantly under the working state of the device, indicating that the device effectively slows down the secondary oxidation of molten steel in the tundish caused by negative pressure at the nozzle.

[0031] Table 3 Comparison of pouring test resul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com