A method for preparing burnt-sweet-flavor style reconstituted tobacco leaves using fenugreek as raw material

A technology of reconstituted tobacco leaves and style, which is applied in the field of preparing reconstituted tobacco leaves with burnt-sweet aroma, which can solve the problems of high irritation, strong woodiness, and poor taste of cigarettes, and achieve the products with sufficient aroma, harmonious aroma characteristics, and less loss of aroma substances Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] In this embodiment, the method for preparing burnt-sweet-flavor style reconstituted tobacco leaves with fenugreek as raw material is as follows:

[0030] 1. Dry the stems and leaves of fenugreek and beat them into 3-5mm diameter fenugreek fragments;

[0031] 2. Mix fenugreek fragments and tobacco powder in a mass ratio of 1:20, extract the mixture of fenugreek fragments and tobacco powder by using a three-stage countercurrent extraction method, and perform solid-liquid separation of the obtained extract to obtain Huluba The extract of the mixture of huluba chips and tobacco powder and the mixture slag; the solid content of the extract of the mixture of huluba chips and tobacco powder is controlled at 7.5-8.0%, and the extrusion dryness of the mixture slag is ≥25%.

[0032] The extraction conditions of each stage in the three-stage countercurrent extraction are: the mass ratio of fenugreek fragments to tobacco powder mixture and water is 1:6, the extraction temperature i...

Embodiment 2

[0038] For the preparation process of this example, refer to Example 1. The difference is that in Step 2, fenugreek fragments and tobacco powder are mixed in a mass ratio of 1:10, and the obtained sample number is TF-2.

Embodiment 3

[0040] For the preparation process of this example, refer to Example 1. The difference is that in Step 2, fenugreek fragments and tobacco powder are mixed at a mass ratio of 1:5, and the obtained sample number is TF-3.

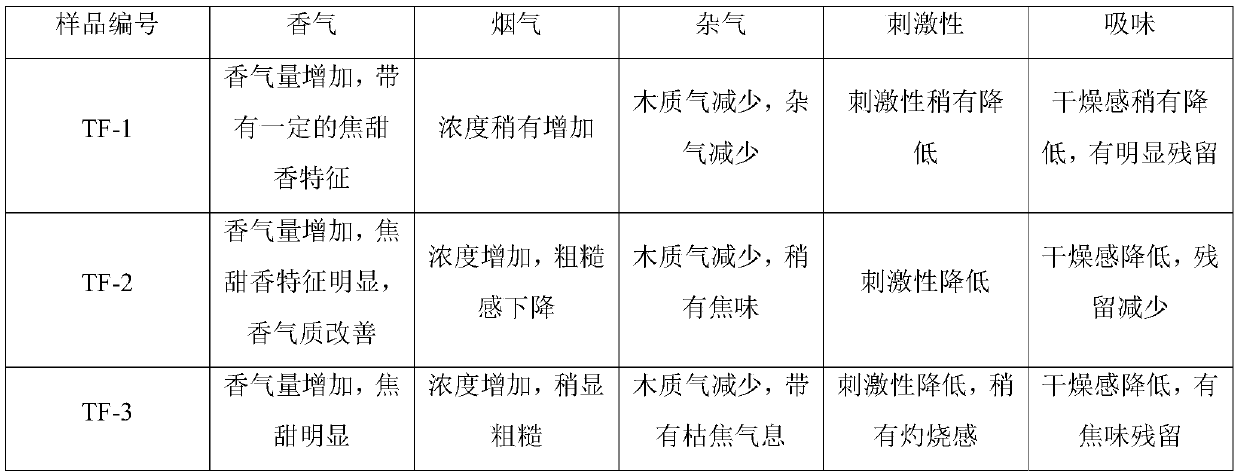

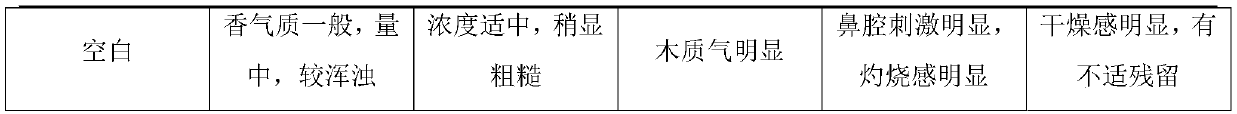

[0041] The reconstituted tobacco leaves obtained in the examples were compared with the blank reconstituted tobacco leaves prepared under the same conditions with a mass ratio of tobacco stems and tobacco dust at 1:1, and their physical properties were measured respectively. The results are shown in Table 1.

[0042] Table 1 Physical properties of huluba reconstituted tobacco leaves

[0043] Sample serial number Tensile strength / kN m -1

Filling value / cm 3 g -1

Bulk thickness / cm 3 g -1

TF-1 0.87 6.35 2.14 TF-2 0.81 6.42 2.07 TF-3 0.83 6.57 2.25 blank 0.86 6.31 2.11

[0044] It can be seen from the above table that the tensile strength of the reconstituted tobacco leaves prepared by using a certa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com