A tray fastening device and plasma processing equipment

A technology of fastening device and processing equipment, applied in crystal growth, semiconductor/solid-state device manufacturing, electrical components and other directions, can solve the problems affecting the 3' loading efficiency of sapphire substrates, cumbersome process, etc., and improve the loading efficiency , The effect of simplifying the fixing steps and simplifying the loading process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

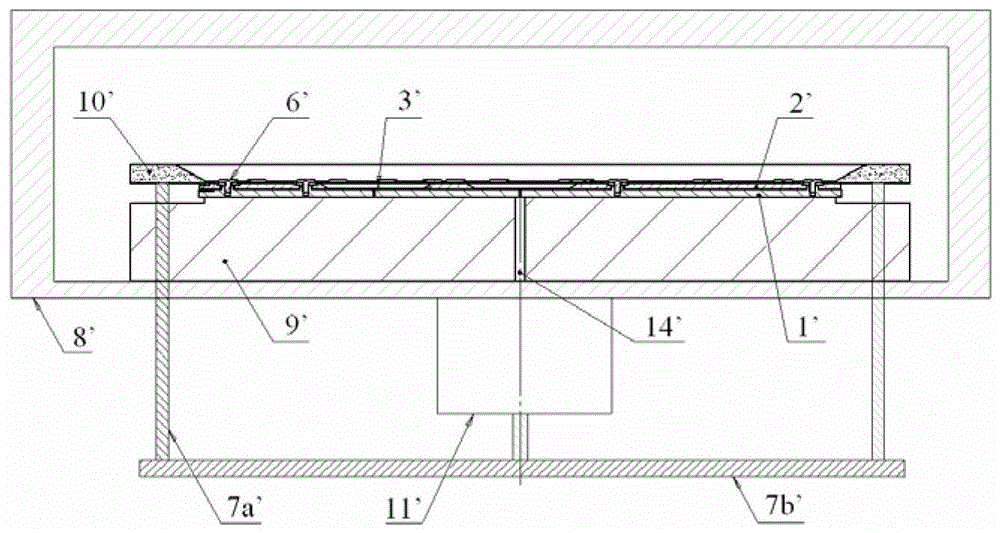

[0037] In order to enable those skilled in the art to better understand the technical solution of the present invention, a pallet fastening device and plasma processing equipment provided by the present invention will be described in detail below with reference to the accompanying drawings.

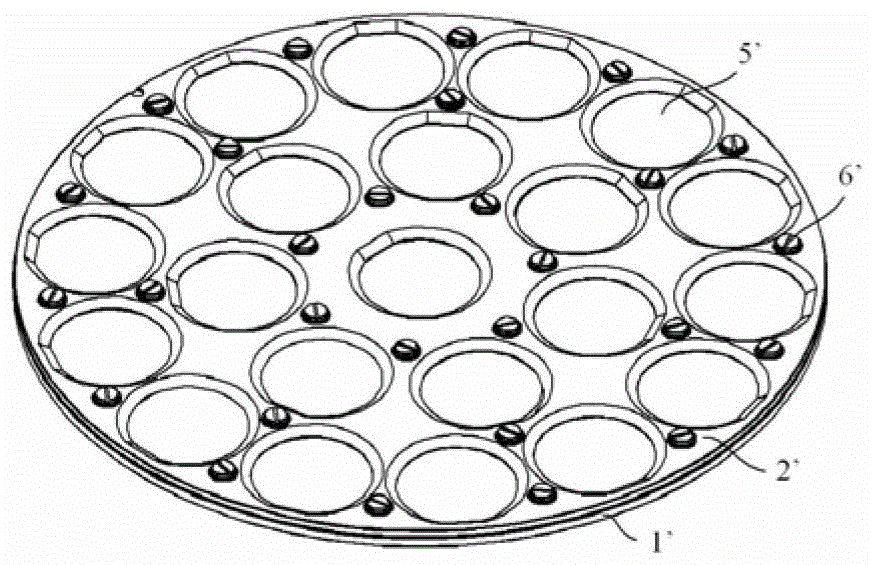

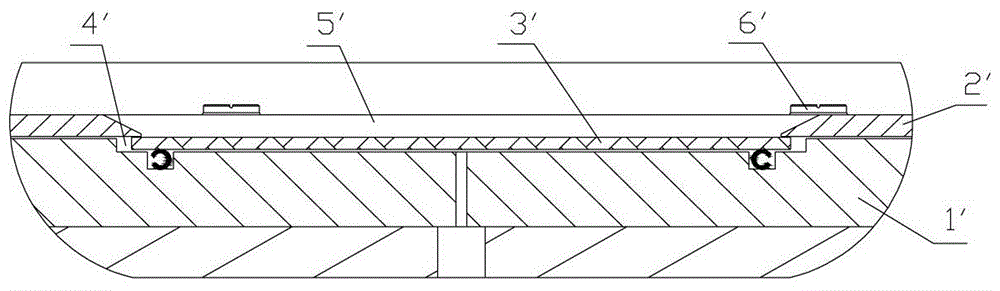

[0038] Figure 4 A cross-sectional view of a plasma processing device provided by an embodiment of the present invention. see Figure 4 , the plasma processing equipment includes a reaction chamber 20, a tray 1, a support table 9 and a tray fastening device, the support table 9 is arranged at the bottom of the reaction chamber 20, the tray 1 is used to carry the wafer 3, and the tray 1 is placed on the support The upper surface of platform 9. The tray fastening device is used to fix the wafer 3 on the loading surface of the tray 1 and fix the tray 1 on the upper surface of the support table 9 .

[0039] The tray fastening device of this embodiment includes a fastener 2 and a force appl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com