Knotted fishing net machine pore plate moving device

A technology for sports equipment and fishing nets, which is applied to transmission equipment, knotting nets, knotting, etc., can solve problems such as products that have not yet appeared, and achieve the effects of convenient design and analysis, large contact area, and cost saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

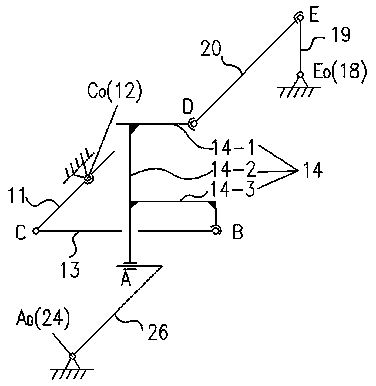

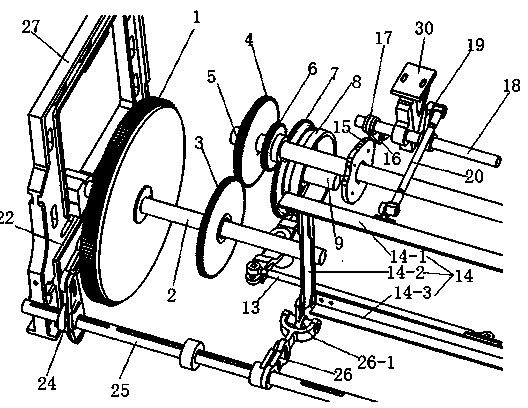

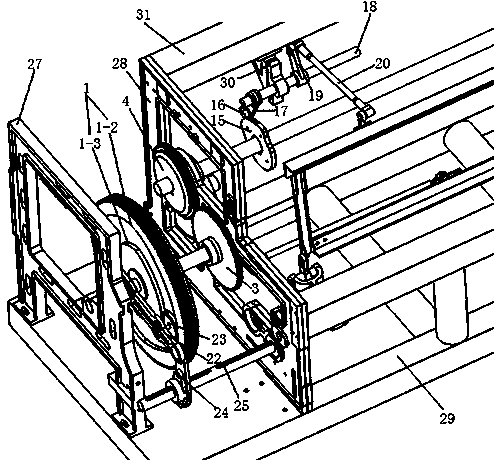

[0026] In the fishing net machine of the present invention, one side in the length direction of the whole machine is the machine head, and the other side is the machine tail. figure 2 , 3 , 4 shows the structural diagram of one side of the nose.

[0027] Such as figure 2 , 3 , 4, 5, and 6, the orifice moving device for a knotted fishing net machine of the present invention includes a gear cam assembly (1), gears (3, 4, 6), and is used to support the gear cam assembly (1) and The main shaft (2) for the rotation of the gear (3), the rotary shaft (5) for supporting the rotation of the gear (4) and the gear (6), the gear cylindrical cam combination, the rotary shaft for supporting the rotation of the gear cylindrical cam combination (9), swing arms (11, 17, 19, 24, 26), swing shafts (18) for supporting swing arms (17) and swing arms (19), swing arms for supporting swing arms (11) Balance shaft (12), rods (13, 20, 22), orifice plate composed of first orifice plate (14-1), sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com