Hydraulic supporting dam

A hydraulic support and support plate technology, which is applied in water conservancy projects, sea area engineering, coastline protection, etc., can solve problems such as small support force, damage to support rods, and low structural strength, and achieve reasonable structural design, portable operation, and increased support strength and the effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

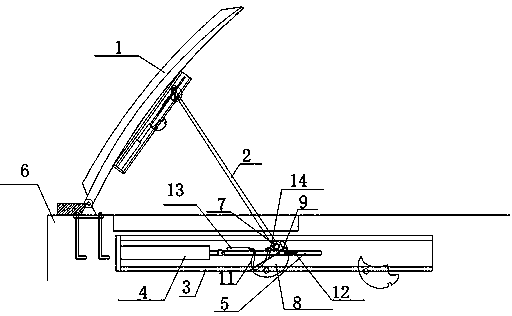

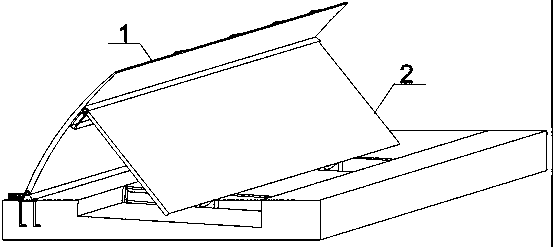

[0025] A kind of hydraulic support dam reference of this embodiment Figure 1-7 , comprising a water-retaining shield 1 anchored to the base plate 6, the base plate 6 is provided with a lifting and automatic locking device, and the linear support device realizes the water-retaining shield 1 through the lifting and automatic locking device. continuous height adjustment;

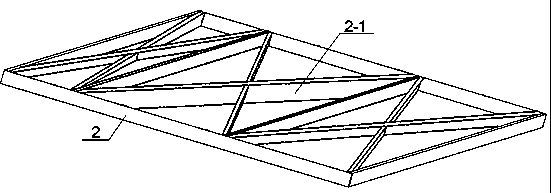

[0026] The linear support device adopts a support plate 2 connected with the water retaining shield 1 in a line contact structure; the support plate 2 is a steel skeleton plate with reinforcing ribs 2-1 inside; the reinforcement The connection form of the rib 2-1 is a triangular plate support structure, which specifically includes longitudinal ribs transversely connected to the two long sides of the support plate 2 and cross ribs connected between the two longitudinal ribs;

[0027] The lifting and automatic locking device includes a guide groove 3 installed on the base plate 6 and a master cylinder 4 located...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com