Non-welding assembly type finished open ditch

A prefabricated and open ditch technology, applied in water supply installations, waterway systems, drainage structures, etc., can solve the problems of difficult cleaning, aging, trachoma in welding points, and avoid on-site welding operations, waterproof construction procedures, etc. The effect of shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

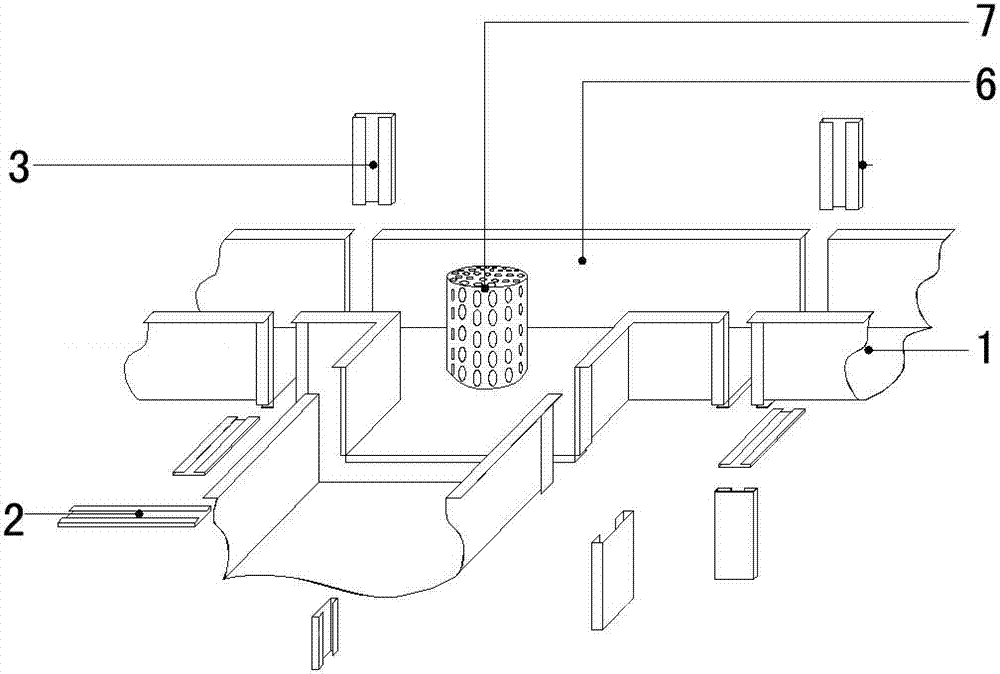

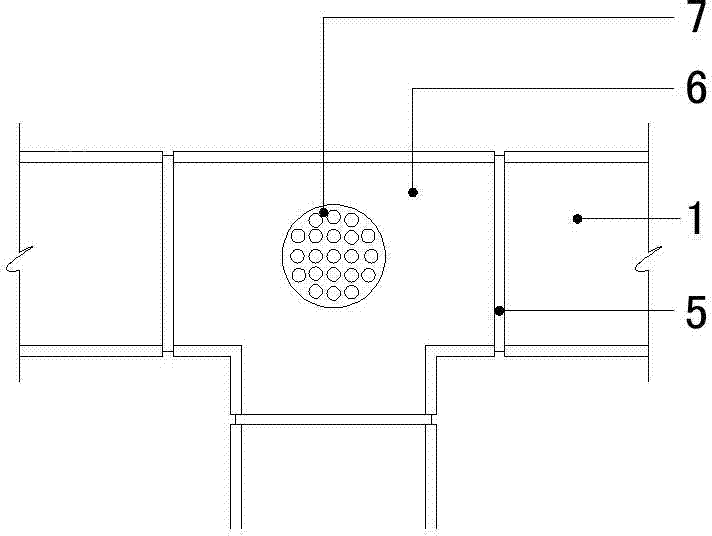

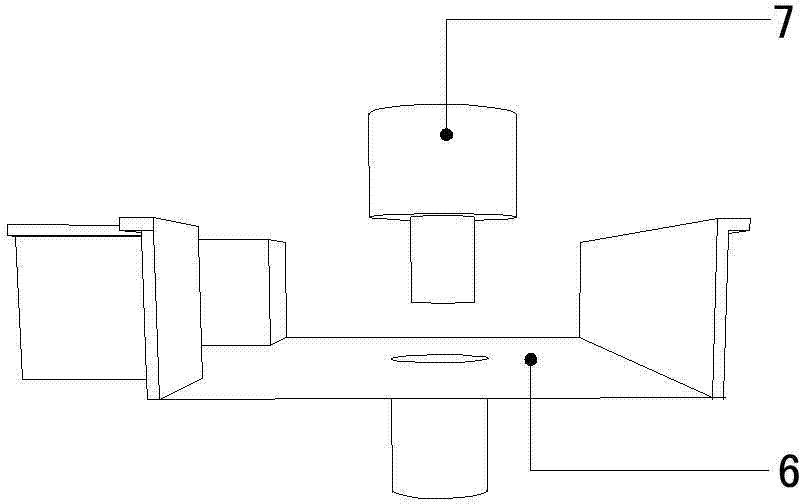

[0018] Example: such as figure 1 , figure 2 As shown, a weldless assembled finished open ditch, which includes an open ditch assembly and a connecting fastener, the open ditch assembly includes a stainless steel finished open ditch assembly 1, and a sewer integrated open ditch assembly 6, the stainless steel finished open ditch assembly 1 and the stainless steel finished open ditch The components 1 are connected by connecting fasteners to form an integral body, and the finished stainless steel open ditch components 1 and the sewage integrated open ditch components 6 are connected by connecting fasteners to form an integral body.

[0019] The edge of the stainless steel finished open ditch assembly 1 is a U-shaped open ditch assembly bending part, and the edge of the sewer integrated open ditch assembly 6 is a U-shaped open ditch assembly bending part. The connecting fastener is in the shape of a plate, and the two sides of the connecting fastener used for fastening are the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com