Cast-in-place reinforced concrete haunched beam structure

A technology of reinforced concrete and adding haunch beams, which is applied in the direction of building structure and construction, can solve the problems of overall structural material and self-weight increase, beam height, cost increase, etc., so as to facilitate the layout of pipelines, increase the net height of rooms, The effect of controlling costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

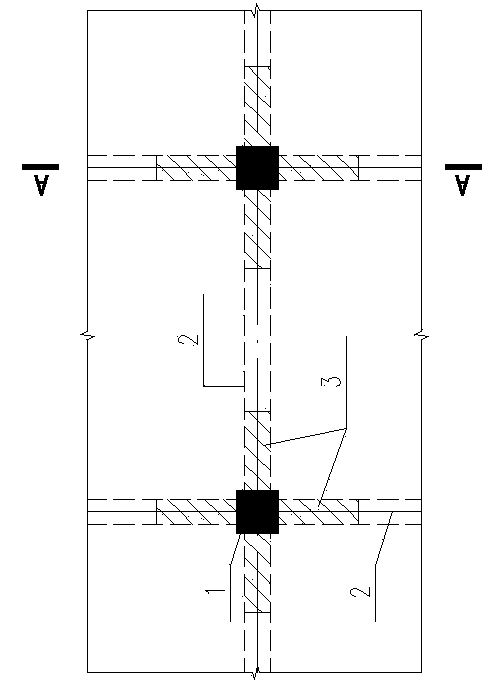

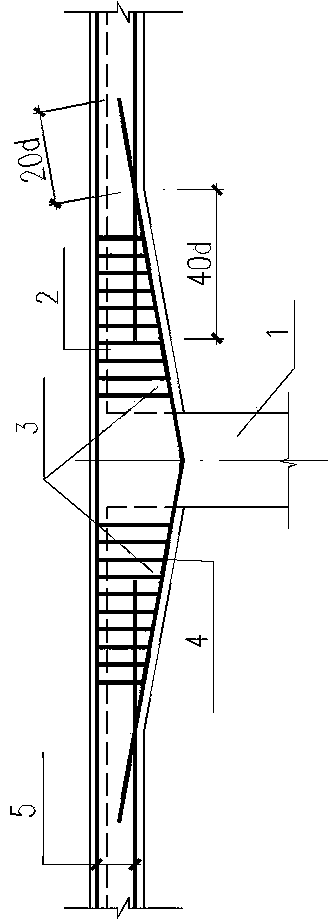

[0020] like figure 1 and figure 2 As shown, it includes a plurality of vertical frame columns 1, the top of frame column 1 is horizontally connected by frame beam 2, and frame column 1 is connected to frame beam 2, and beam support plus armpit area 3 is set at the position of cast-in-place reinforced concrete beam support , configure the oblique reinforcement in the haunch area 3 and form mutual anchorage with the lower reinforcement in the middle reinforcement 5 of the beam span, and realize the increase of the bending section of the support.

[0021] The construction process of cast-in-place reinforced concrete plus haunch beam structure is as follows:

[0022] First erect the floor suppor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com