A construction method of forced mixer

A technology of forced mixer and construction method, which is applied in construction, building structure, processing of building materials, etc., can solve the problems that the concrete mixing machinery and equipment cannot be arranged, is not suitable for mixing viscous concrete, and the mixing volume is small at one time, so as to shorten the time. Construction time, reliable performance, no dust pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

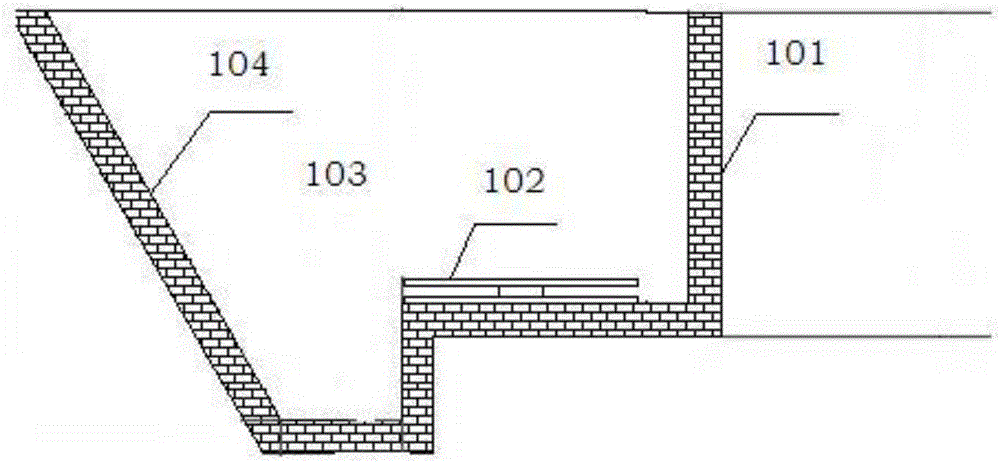

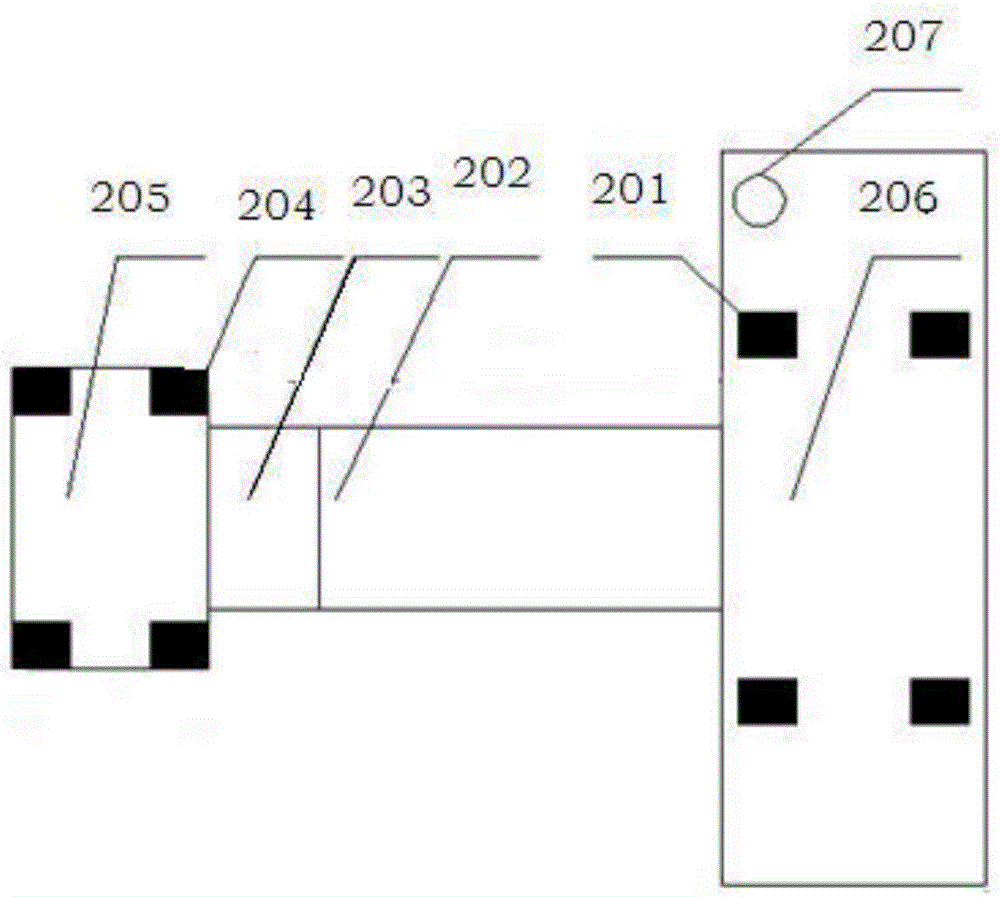

[0028] As shown in the figure, a forced mixer construction device includes a side wall 101, an I-beam 102, a weighing bucket groove 103, a slope 104, a batching machine column 201, a mixer foundation pit 202, a transport track 203, and a mixer column 204. Mixer 205, batching machine 206, manhole 207, cement storage tank 301, screw conveyor 302. The I-beam 102 pads the batching machine 206, the slope 104 is connected to the weighing bucket groove 103, the batching machine 206 is connected to the batching machine column 201, the mixer 205 is connected to the mixer column 204, and the transportation track 203 is connected to Mixer foundation pit 202, the inspection hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com