A vibration stirring durable cement stabilized macadam device and a construction method thereof

A technology for stabilizing crushed stone and vibrating agitation of cement, applied in the field of mixer research, can solve the problems of reduced load resistance and stability, prone to local subsidence, difficult to mix evenly, etc., and achieves good microscopic uniformity, circulatory flow and diffusion distribution. The effect of strengthening and enlarging the area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

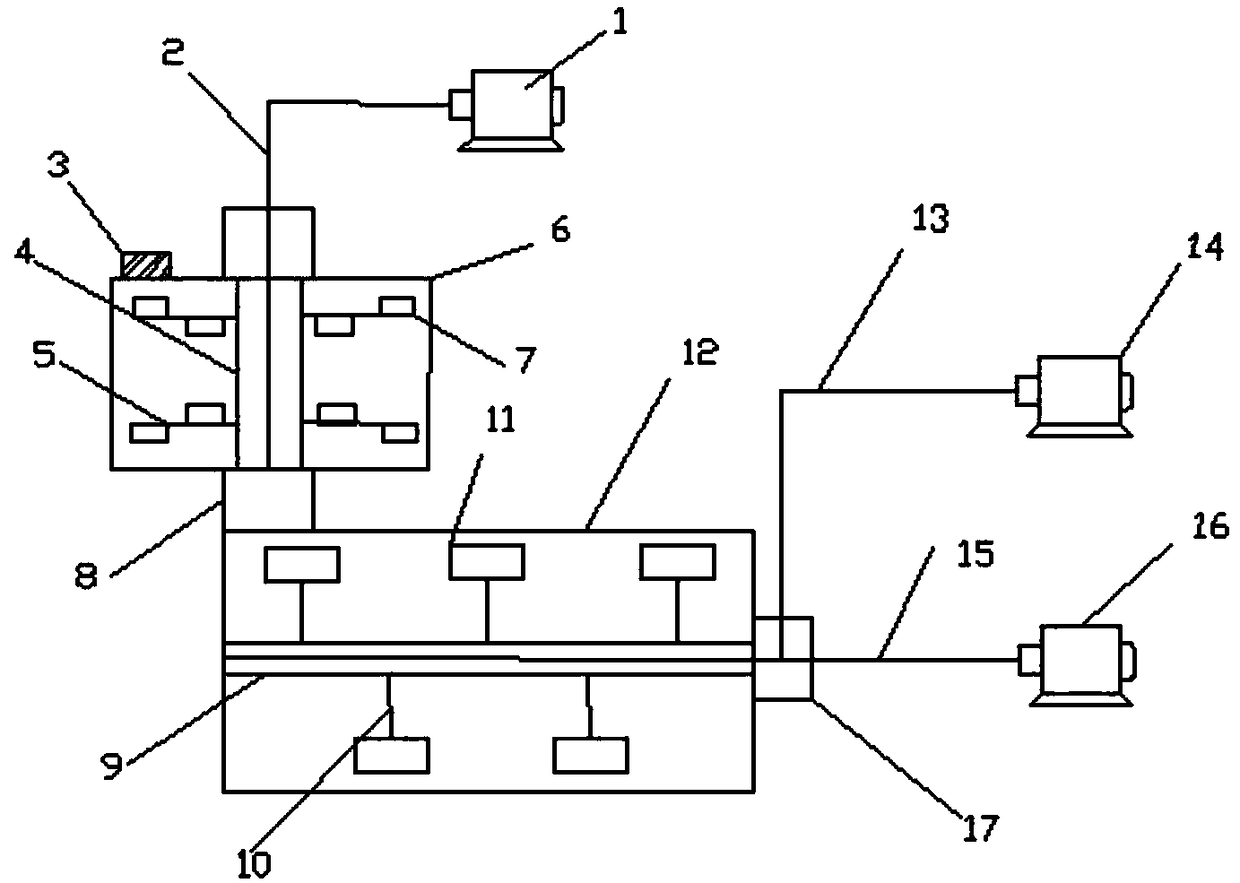

[0026] A vibration-stirring durable cement-stabilized gravel device, comprising a vertical-shaft stirring mechanism and a horizontal-shaft stirring mechanism; the vertical-shaft stirring mechanism includes a first stirring motor 1, a first conveyor chain 2, a feed port 3, a Stirring shaft 4, first stirring arm 5, vertical shaft mixing drum 6, first stirring blade 7, connecting belt 8; the horizontal shaft stirring mechanism includes a second stirring shaft 9, a second stirring arm 10, a second stirring blade 11. Horizontal shaft mixing drum 12, second conveying chain 13, second stirring motor 14, third conveying chain 15, vibration motor 16, support bearing 17; the first stirring motor 1 passes through the first conveying chain 2 Connect with the first stirring shaft 4 and drive the first stirring shaft 4 to stir, the first stirring shaft 4 is vertically arranged at the rotation center position of the vertical shaft type mixing drum 6, and the first stirring shaft 4 The surfac...

Embodiment 2

[0036] The difference from Embodiment 1 is that six first stirring arms 5 are fixedly installed on the first stirring shaft 4 , and each first stirring arm 5 is provided with four first stirring blades 7 .

Embodiment 3

[0038] The difference from Embodiment 1 is that eight first stirring arms 5 are fixedly installed on the first stirring shaft 4 , and each first stirring arm 5 is provided with six first stirring blades 7 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com