Real-time levelness monitoring system for workbench of 3D (three-dimensional) printer

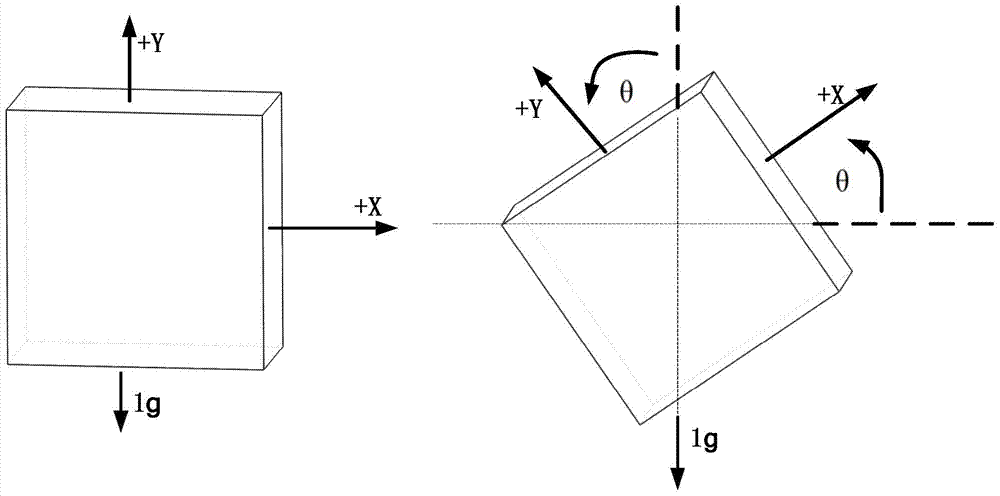

A 3D printer and monitoring system technology, used in measuring devices, mapping and navigation, measuring inclination, etc., can solve the problems of real-time monitoring of the working platform, difficult to detect the working platform, and difficult to control the accuracy, and achieve easy electrical control and maintenance. , The leveling operation is accurate and easy to control, and the cost is low.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

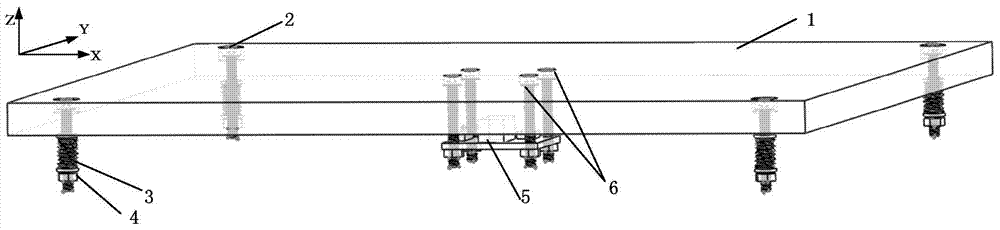

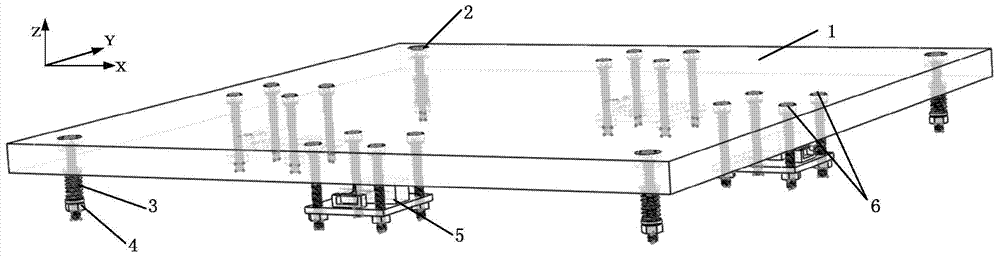

[0020] Below, the area of the working platform is greater than 500×500mm 2 Taking time as an example, the present invention will be further described in detail in conjunction with the accompanying drawings and specific embodiments:

[0021] A real-time level monitoring system for a 3D printer working platform, such as image 3 and Figure 5 As shown, the system includes four biaxial inclination sensor modules, a microcontroller, four indicator lights and a buzzer, and the four biaxial inclination sensor modules are respectively installed in parallel and fixed in the middle of the four edges of the lower side of the working platform , the microcontroller is respectively connected to the four biaxial inclination sensor modules through the chip select port CSX, and the chip select port controls the connection and disconnection of the two, and the data input terminal of the microcontroller is connected to the The data output end of each biaxial inclination sensor module is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com