Method for controlling calibration device of wave height meter and accelerometer

A technology of accelerometer and calibration device, which is applied in the testing/calibration of speed/acceleration/shock measurement equipment, speed/acceleration/shock measurement, and measurement devices, etc., to achieve cost reduction, large adjustment range, and performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to better understand the above technical solutions of the present invention, a further detailed description will be given below in conjunction with the drawings and embodiments.

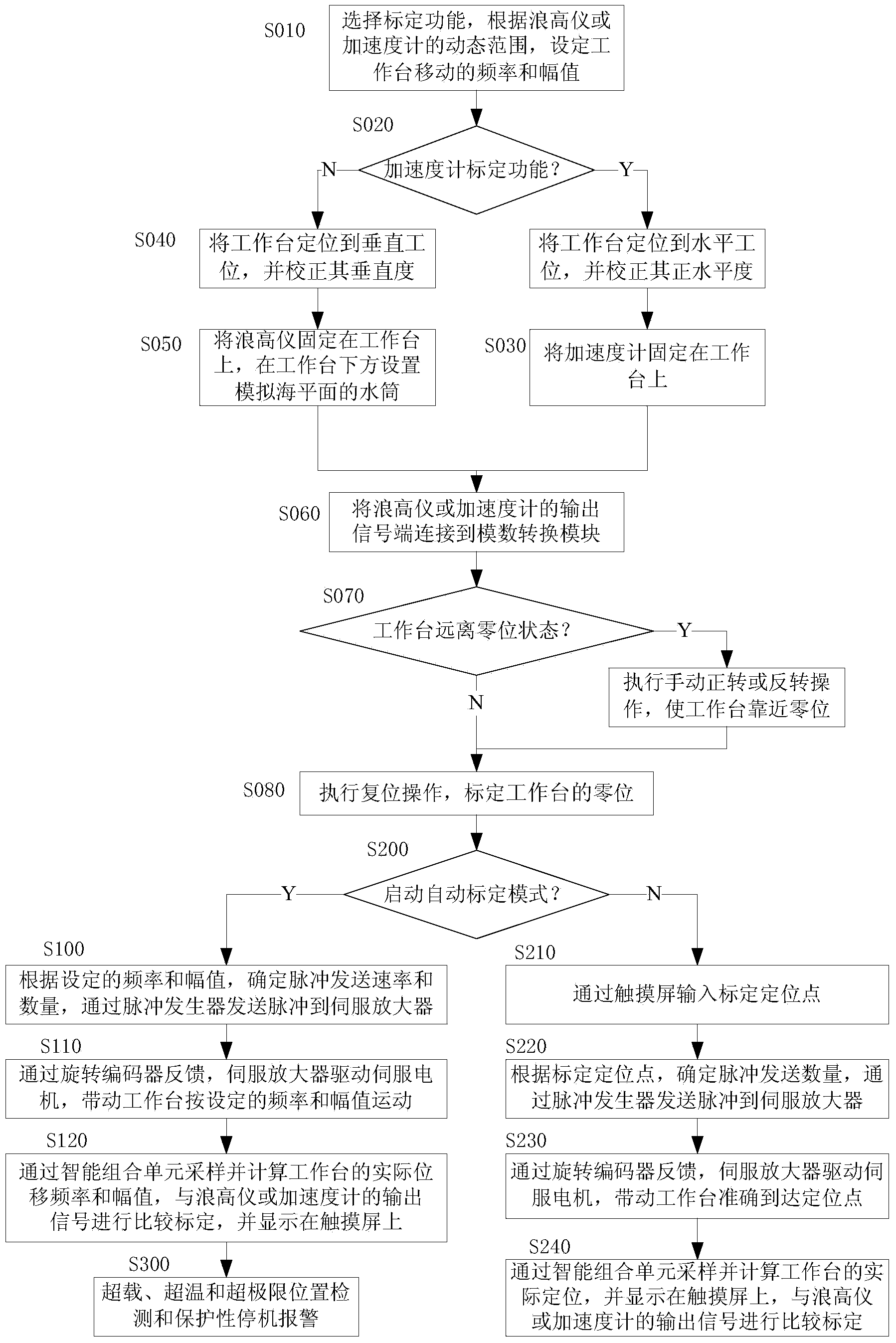

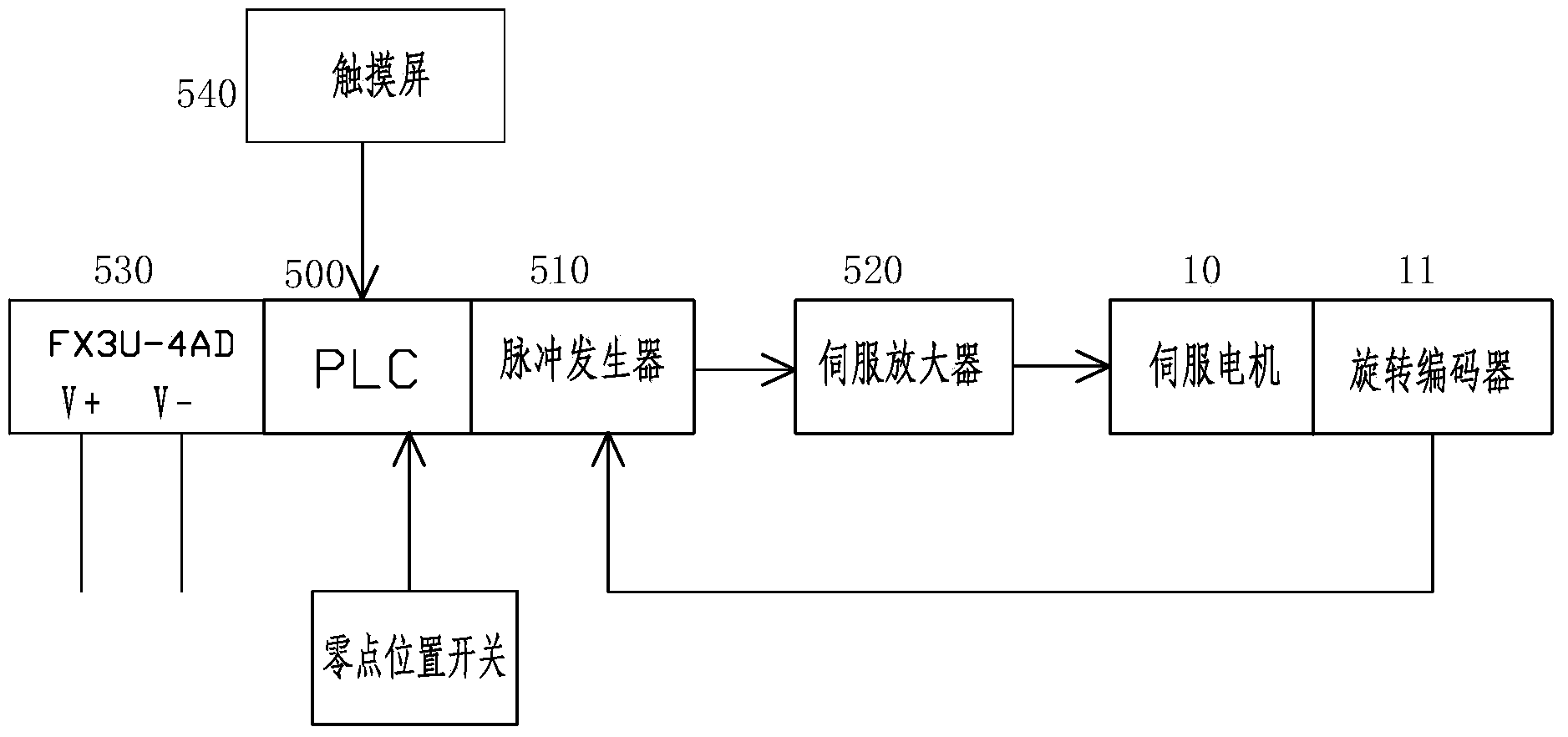

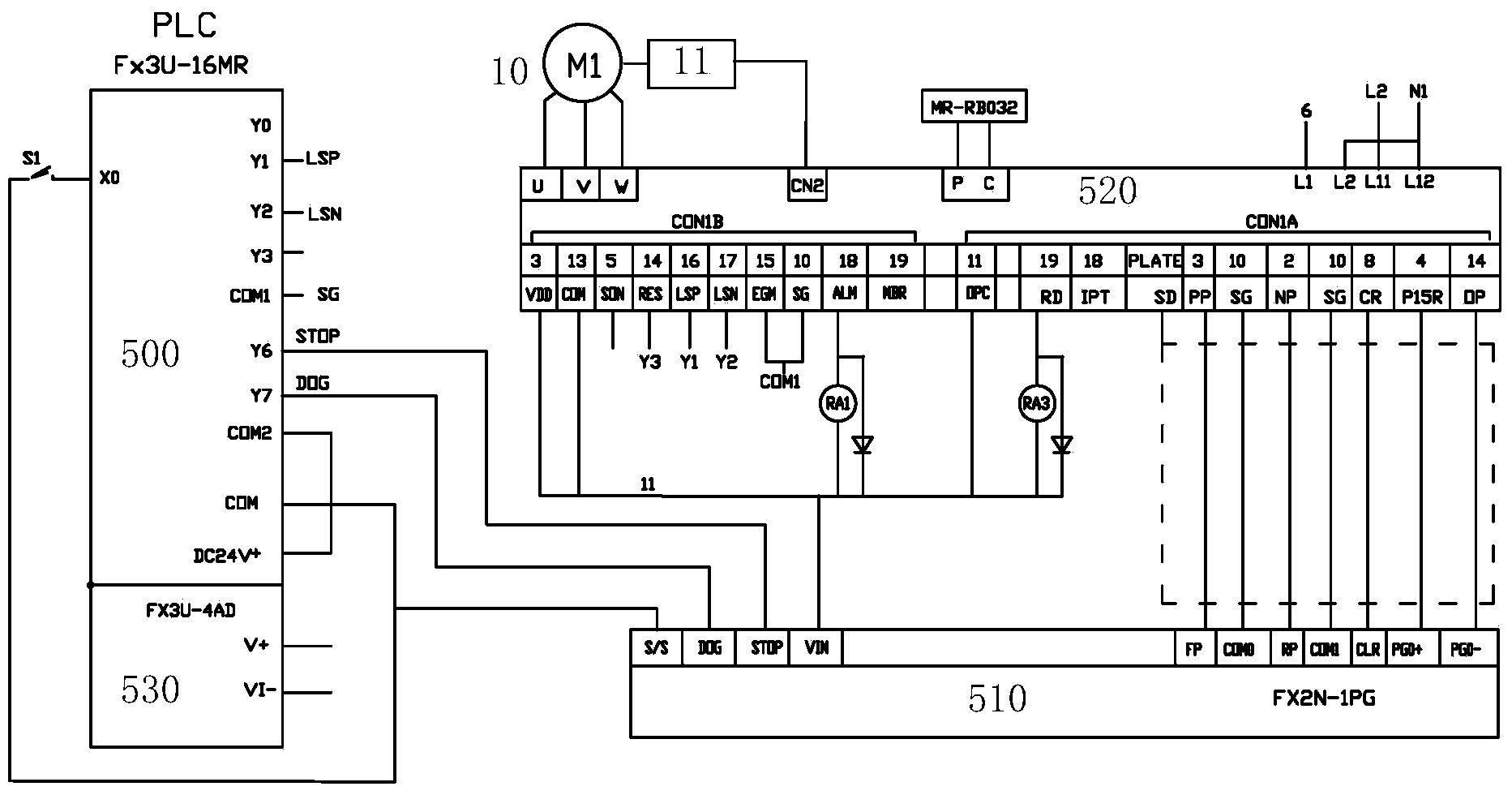

[0036] The control flow of an embodiment of the control method of the wave height meter and the accelerometer calibration device of the present invention is as follows figure 1 As shown, the wave height meter and accelerometer calibration device includes a workbench 2 driven by a servo motor 10. The workbench 2 is used to fix the wave height meter and accelerometer. Combination unit 1 drives table 2, see Figure 4 and Figure 5 . The circuit structure of the control device 7 of the wave height instrument and the accelerometer calibration device is as follows: figure 2 and image 3 As shown, it is composed of a PLC host 500 , a pulse generator 510 , a servo amplifier 520 , an analog-to-digital conversion module 530 and a touch screen 540 . exist figure 2 and image 3 In the sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com