Integrated directional non-contact cable fault detection positioning sensing device

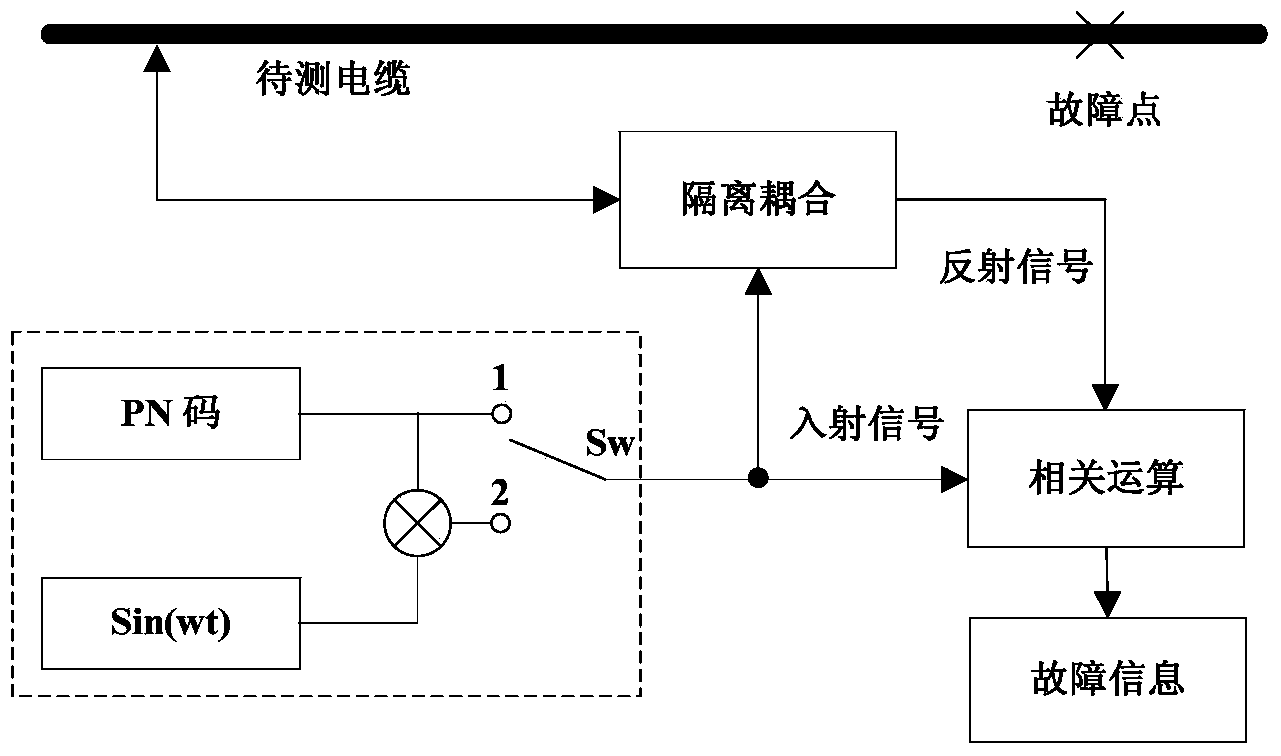

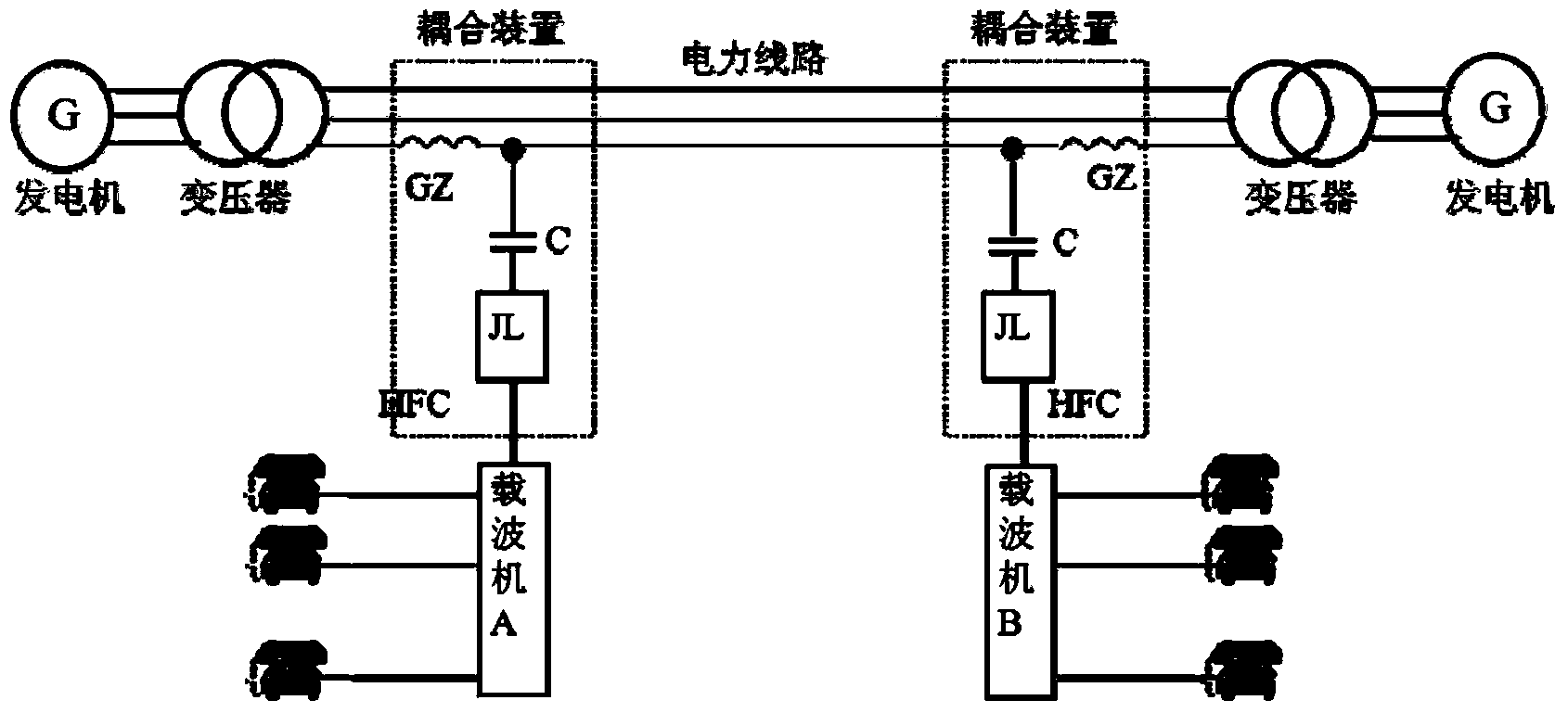

A technology of cable fault and positioning sensing, which is applied in the direction of fault location, measuring device, fault detection by pulse reflection method, etc., can solve the problem of destroying the structure of the power line system, achieve high safety, avoid electrical connection, and increase magnetic permeability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

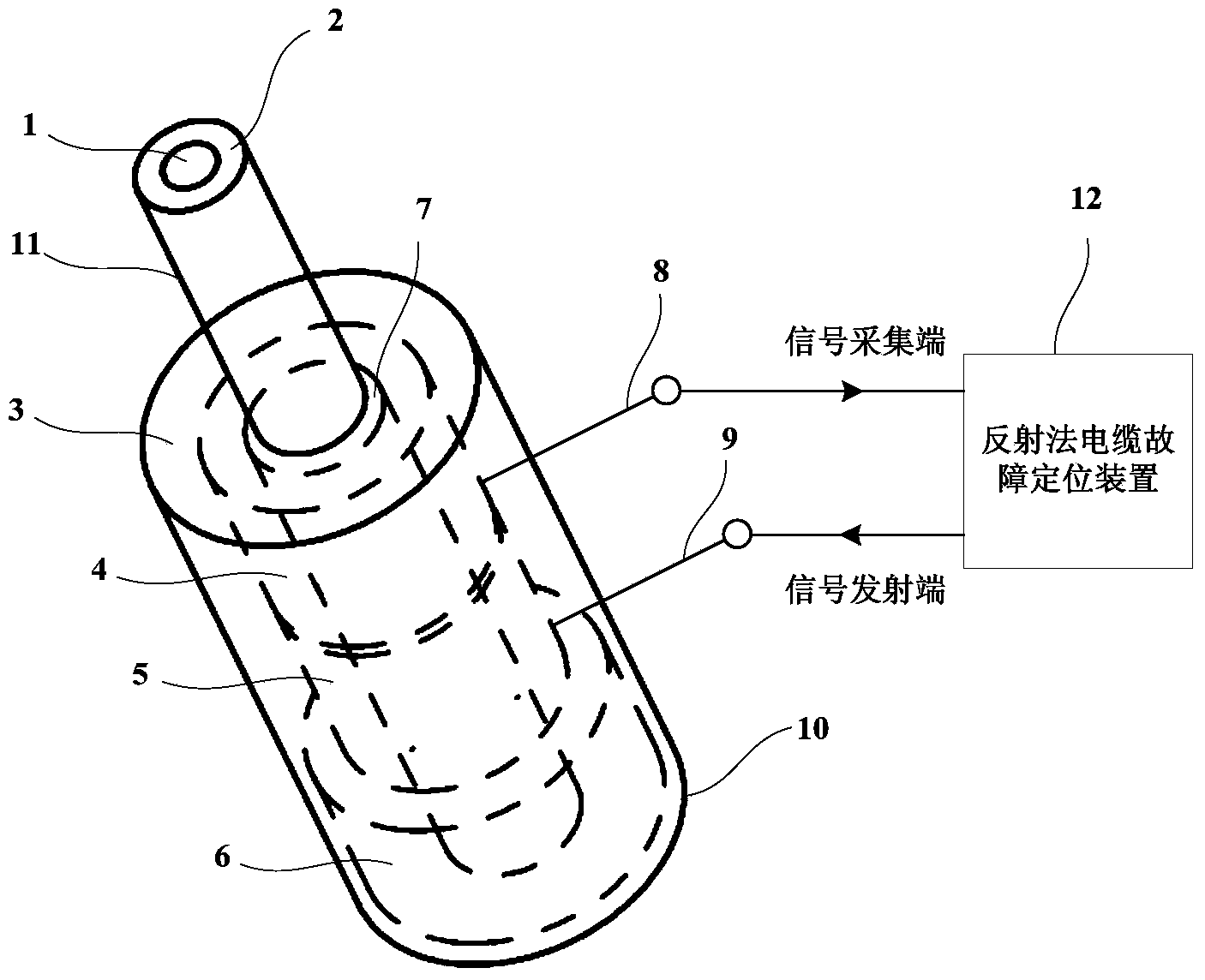

[0035] The technical solution of the invention will be described in detail below in conjunction with the accompanying drawings.

[0036] image 3The integrated directional non-contact cable fault detection and positioning sensing device shown in , which includes a magnetic ring 6, two conductor rings 4, 5, when detecting and positioning, the three are set on the cable to be tested. A buffer pad 7 made of elastic insulating material is provided between the magnetic ring 6, the conductor rings 4, 5 and the cable insulation layer 2 to be tested, and the magnetic ring and the conductor ring are tightly embedded in the insulating jacket 3 in sequence to form an integrated coupling sensor. Sensing device 10. The conductor ring 5 close to the magnetic ring 6 has a lead-out electrode 9, which is connected to the signal transmitting end of the reflection method cable fault location device 12, and the other conductor ring 4 has a lead-out electrode 8, which is connected to the signal c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com