A Copper Strip Surface Defect Detection Method Based on Online Sequence Extreme Learning Machine

A technology of sequence limit and defect detection, which is applied to computer parts, instruments, character and pattern recognition, etc., to achieve the effect of reducing noise and reducing influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

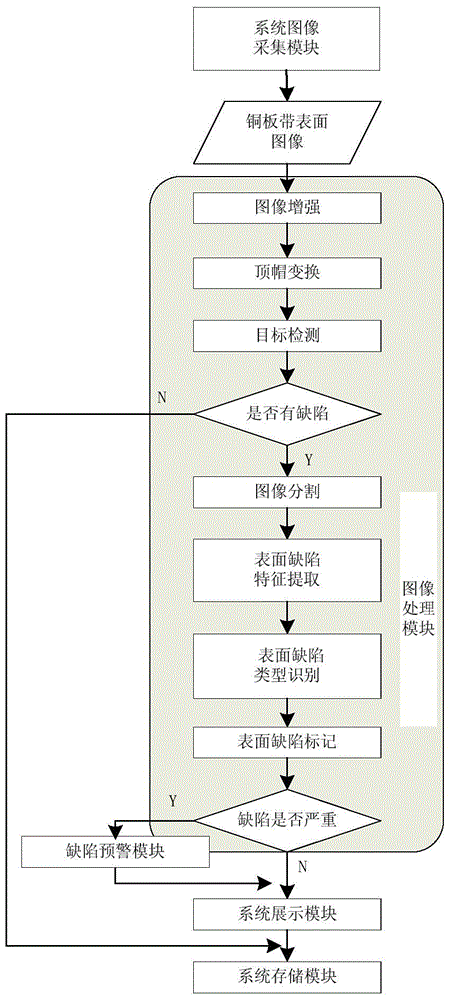

[0107] like figure 1 As shown, the flow chart of the copper strip surface defect detection method of the present invention. First, the image of the surface of the copper strip is acquired through the image acquisition module. Due to the existence of image noise, the subsequent processing effect is affected. It is necessary to denoise and enhance the surface image first. At the same time, in order to reduce the influence of uneven illumination, the surface image Perform top-hat transformation processing. In actual production, the probability of defects on the surface of copper strips is about 5%. Therefore, it is necessary to reduce the amount of calculation and improve the real-time performance of the system through the pre-inspection of surface defect images. Segment the image with surface defects, segment the defects in the surface image, and then extract some geometric and texture features of each defect. Through the trained classifier, the type of surface defect can be i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com