Light low-frequency wideband film metamaterial sound isolator

A metamaterial and thin film technology, applied in the direction of sound-producing equipment, instruments, etc., can solve the problems of prominent low-frequency noise, difficult low-frequency broadband sound insulation of lightweight materials, etc. penetration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

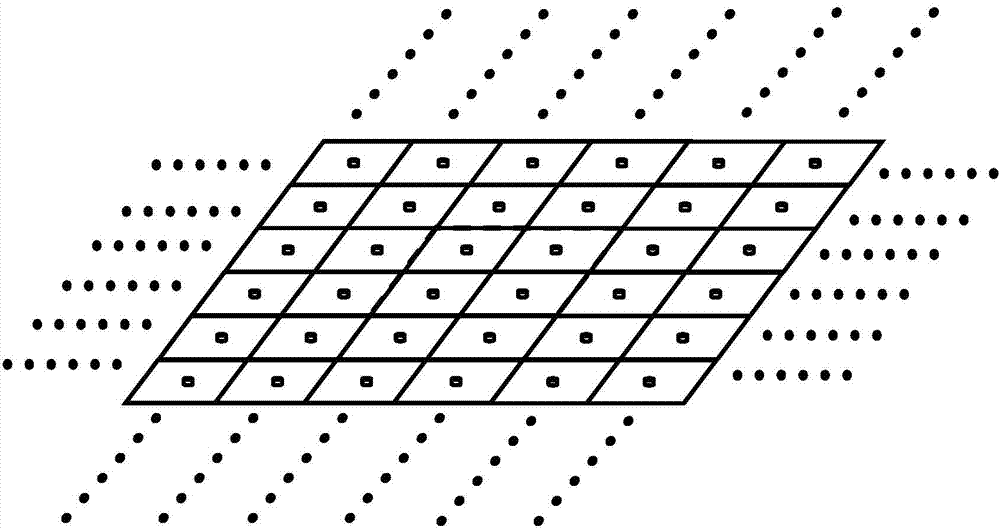

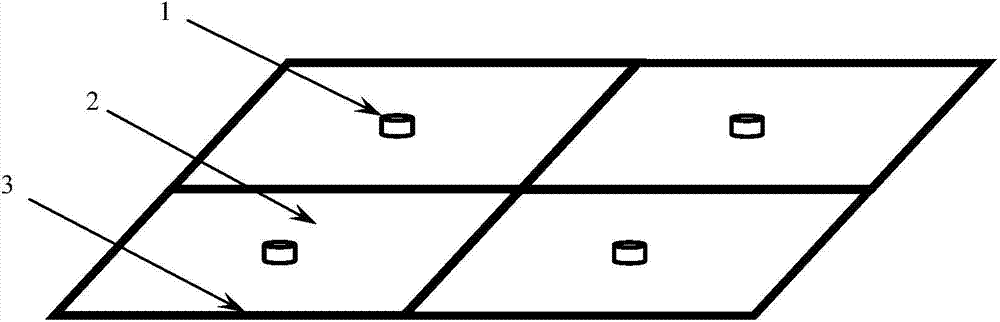

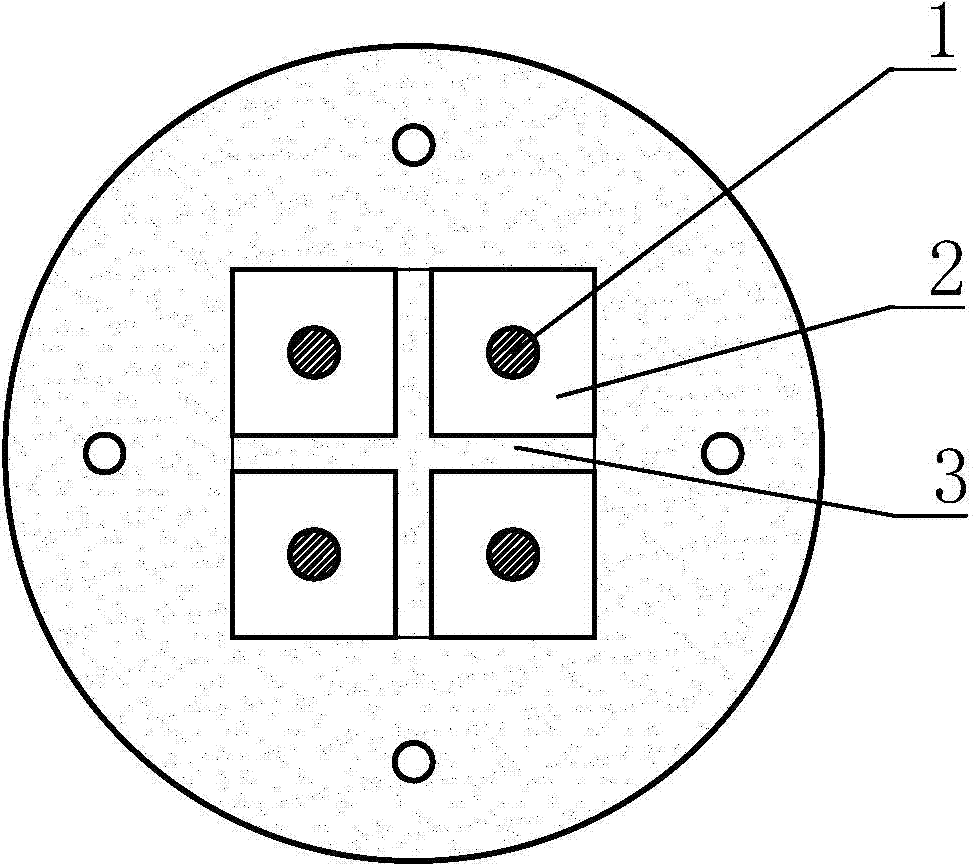

[0023] The present invention is a light-weight low-frequency broadband film metamaterial sound insulation device, such as figure 1 with figure 2 As shown, it is composed of a grid support 3, a viscoelastic film 2 and a counterweight 1; the grid support 3 is made of rigid and lightweight materials, and is formed by periodically extending a square grid along the x direction and the y direction The viscoelastic film 2 is tensioned and bonded on the grid support 3; the counterweights 1 are periodically additionally arranged on the viscoelastic film 2 corresponding to the square grid; the square grid and the corresponding viscoelastic film The elastic film 2 and the counterweight 1 form a cell, which is the smallest acoustic metamaterial unit for blocking low-frequency noise in the sound insulat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Side length | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com