Yoke plate tightener for overhead line stringing

A technology of overhead line and wire tensioner, which is applied in the direction of overhead line/cable equipment, etc., can solve the problems of poor safety of wire tightening of transmission lines, difficulty in fixing double porcelain bottle strings, and low work efficiency, so as to reduce labor intensity and improve line quality. The effect of tight line efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

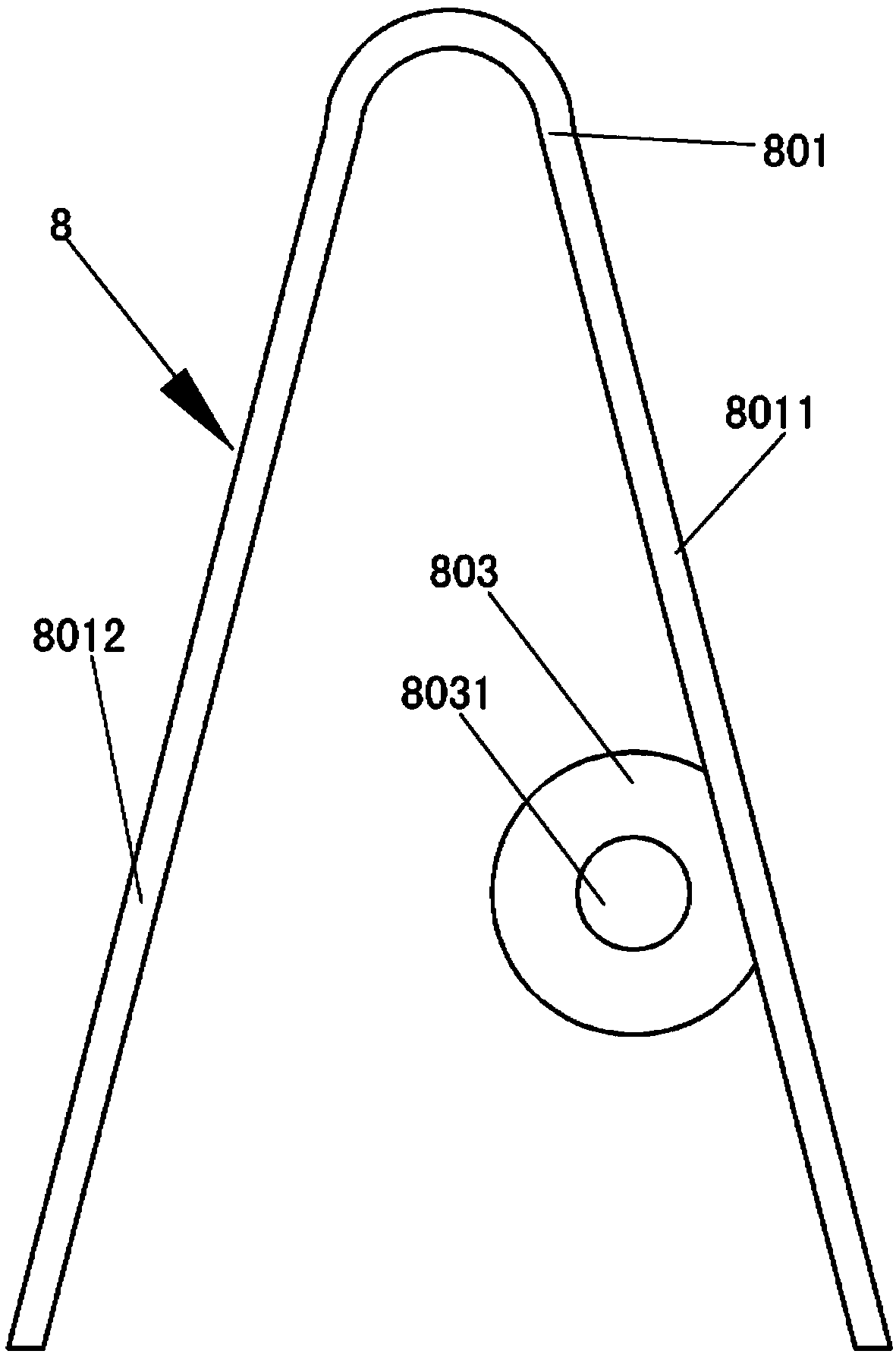

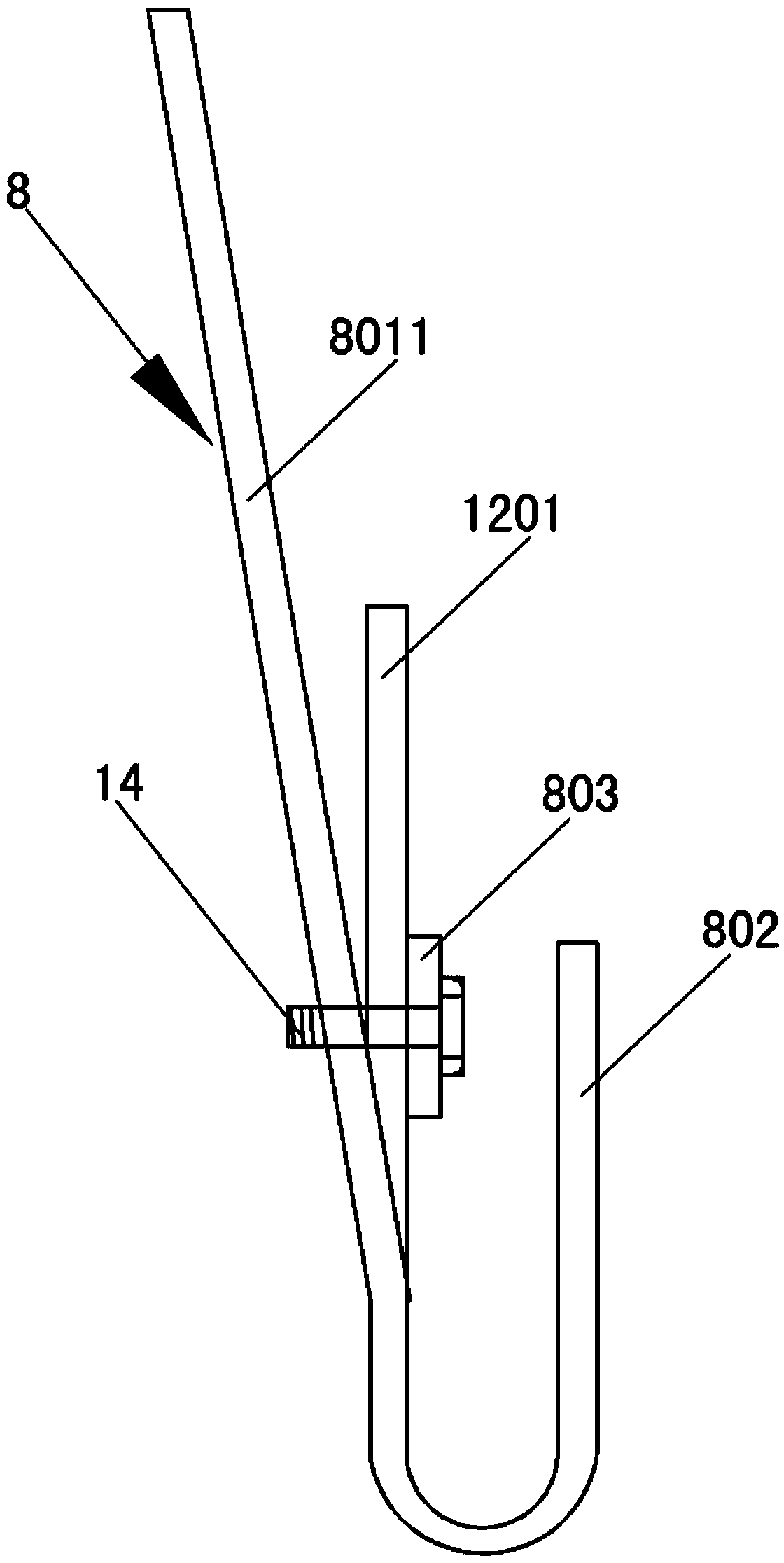

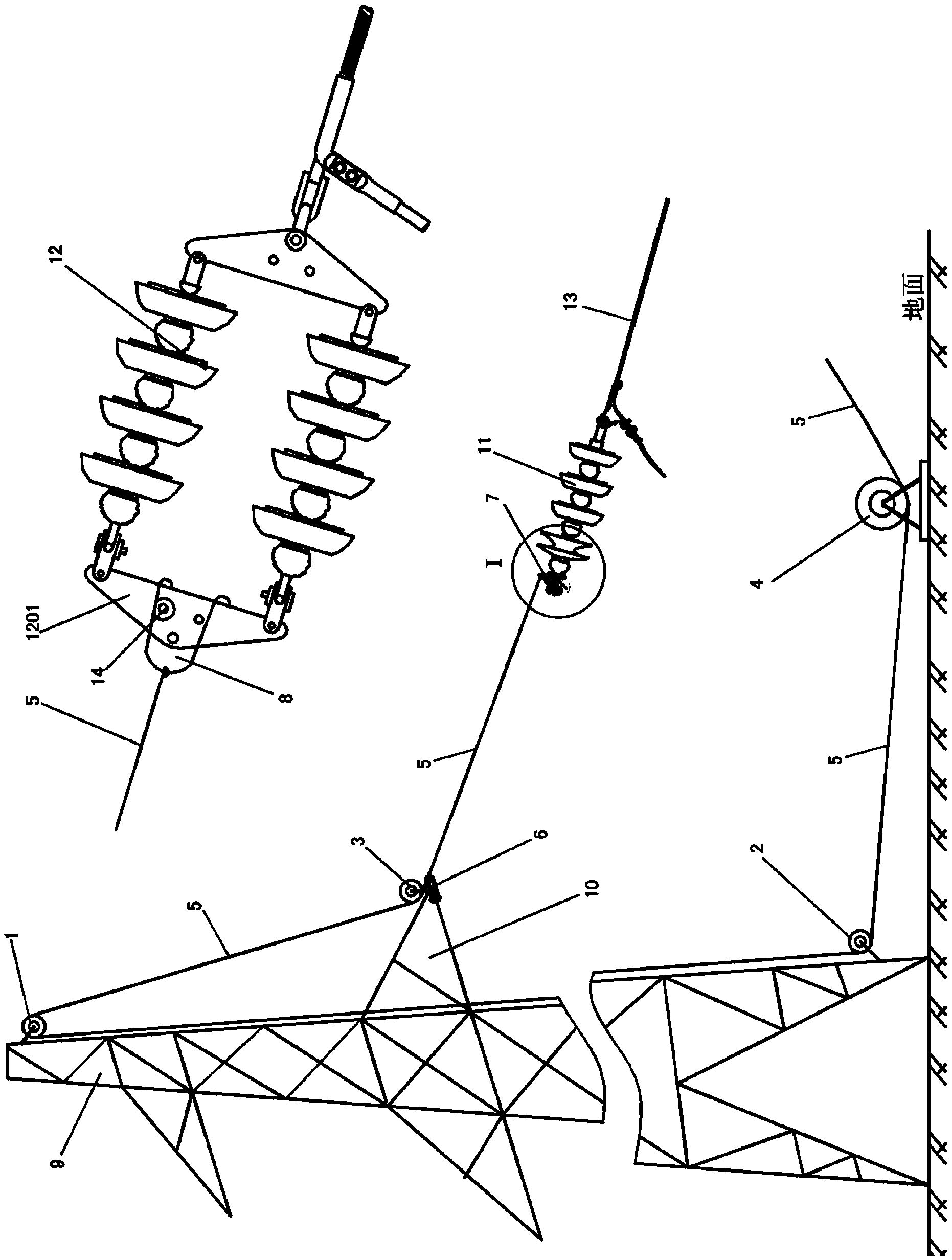

[0029] see Figure 1 ~ Figure 1 0, the connecting plate tensioner 8 for overhead line tightening includes a V-shaped body 801, and the V-shaped body 801 includes two legs, each of which is provided with a hook 802; the legs include a first leg 8011 and a second leg 8012, the first leg 8011 is provided with a fixing plate 803, and the fixing plate 803 is provided with a The thickness direction passes through the fifth through hole 8031 of the fixing plate 803 .

[0030] The two supporting legs of the connecting plate tensioner are made of a steel bar, the steel bar is bent in a V shape, and the bending part is arc-shaped. There is a hook on each leg. During the wire tightening operation, the connecting board wire tightening device is used to connect the double-string porcelain bottles. A connecting plate 1201 is arranged between the two strings of porcelain bottles 12 of the double-stringing porcelain bottles. The connecting plate 1201 is provided with a plurality of throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com