Variable displacement control mode of motor mover with unequal interval

A displacement control and mover technology, applied in electric components, electrical components, electromechanical devices, etc., can solve problems such as large fluctuations, unstable operation, reduction of electromagnetic resultant force, etc., to eliminate the possibility of electromagnetic thrust in the opposite direction, reduce The effect of controlling difficulty, eliminating possibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

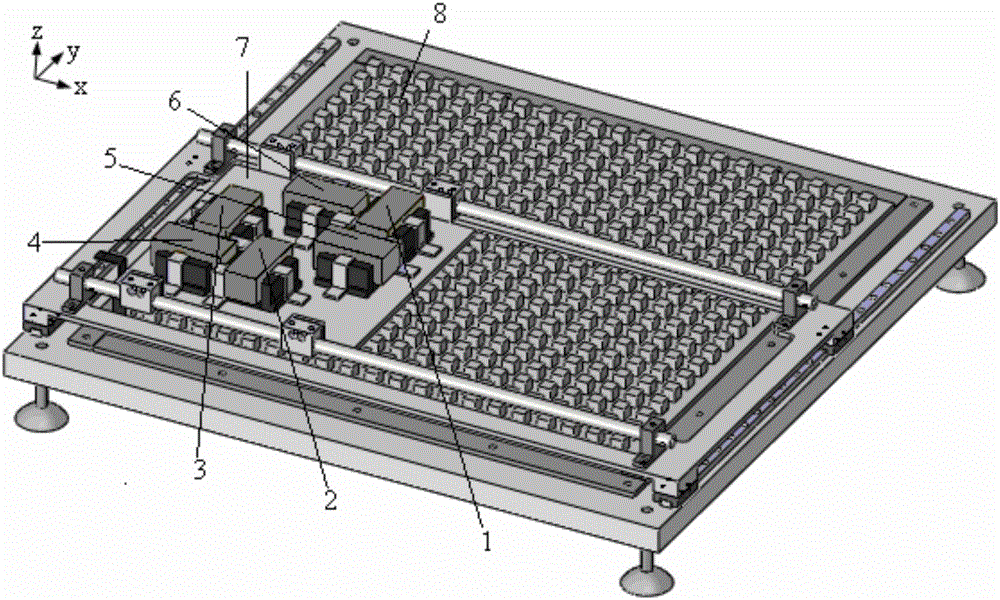

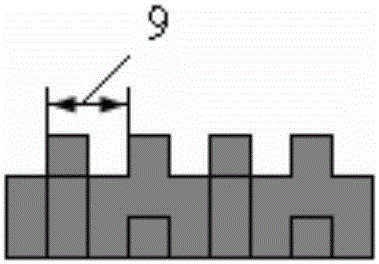

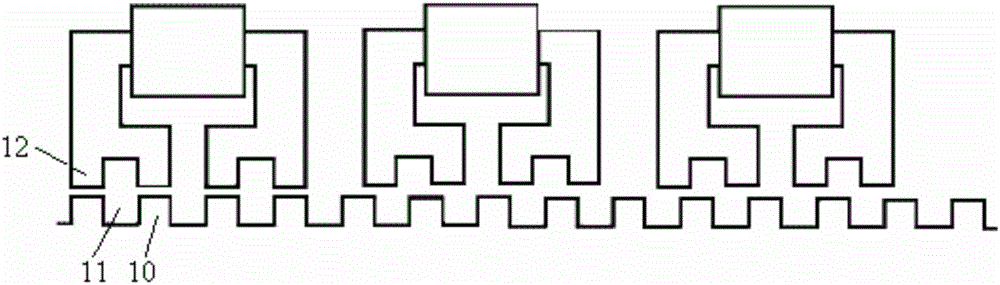

Embodiment approach 1

[0036] The displacement movement of the mover 7 changes periodically, and the movement cycle is equal to the stator pole distance 9, which is 12mm. Each cycle is divided into six operating intervals, and the six different positions of the mover 7 relative to the stator 8 determine the mover. energized state of the sub-winding.

[0037] See Table 2 for the energization sequence of the mover windings when the mover 7 moves to the right or to the left in the x direction.

[0038] Table 2 When the stator pole pitch is 6mm, the "single-phase-two-phase" variable displacement control rotor winding energization sequence

[0039] area

Position range (mm)

Power-on phase sequence when moving to the right

Power-on phase sequence when moving left

1

0~3

X C

X B

2

3~4

x C 、X B

x B 、X C

3

4~7

X B

X C

4

7~8

x B 、X A

x C 、X A

5

8~11

X A

X A

6

11~12

x...

Embodiment approach 2

[0051] The displacement movement of the mover 7 changes periodically, and the movement cycle is equal to the stator pole distance 9, which is 24mm. Each cycle is divided into six operating intervals, and the mover 7 is determined by six different positions of the mover 7 relative to the stator 8. energized state of the sub-winding.

[0052] See Table 3 for the energization sequence of the mover windings when the mover 7 moves to the right or to the left in the x direction.

[0053] Table 3. "Single-phase-two-phase" variable displacement control rotor winding energization sequence when the stator pole pitch is 24mm

[0054] area

Position range (mm)

Power-on phase sequence when moving to the right

Power-on phase sequence when moving left

1

0~5

X C

X B

2

5~8

x C 、X B

x B 、X C

3

8~13

X B

X C

4

13~16

x B 、X A

x C 、X A

5

16~21

X A

X A

6

21~24...

Embodiment approach 3

[0063] The displacement movement of the mover 7 changes periodically, and the movement cycle is equal to the stator pole distance 9, which is 36mm. Each cycle is divided into six operating intervals, and the mover 7 is determined by six different positions of the mover 7 relative to the stator 8. energized state of the sub-winding.

[0064] When the mover 7 moves to the right or to the left in the x direction, the sequence of electrification of the mover windings is shown in Table 4.

[0065] Table 4 When the stator pole pitch is 36mm, the "single-phase-two-phase" variable displacement control rotor winding energization sequence

[0066] area

Position range (mm)

Power-on phase sequence when moving to the right

Power-on phase sequence when moving left

1

0~9

X C

X B

2

9~12

x C 、X B

x B 、X C

3

12~21

X B

X C

4

21~24

x B 、X A

x C 、X A

5

24~33

X A

X A ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com