Polyimide porous body and method for producing same

A technology of polyimide and manufacturing method, which is applied in transportation and packaging, printed circuit, thin material processing, etc. It can solve the problems of harmfulness, inappropriateness, thickening of foaming agent, etc., and achieve mechanical strength and Excellent insulation, low relative permittivity, and excellent heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

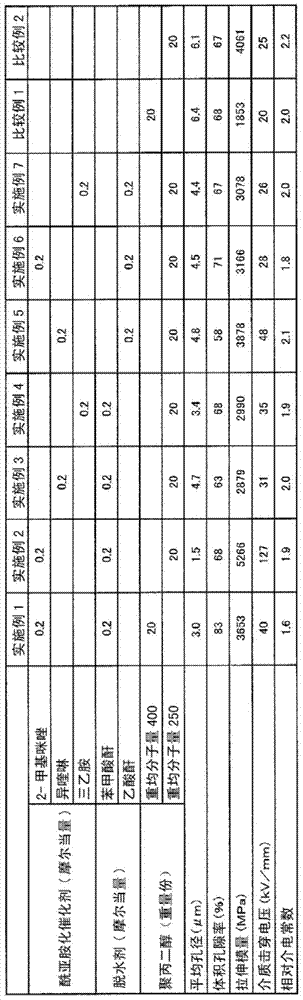

Embodiment 1

[0085] Add 785.3g N-methyl-2-pyrrolidone (NMP), 44.1g p-phenylenediamine (PDA), and 20.4g4,4'-diaminodiphenyl ether (DDE) in a 4-necked flask of 1000ml, Dissolve while stirring at room temperature. Next, add 150.2g of 3,3',4,4'-biphenyltetracarboxylic dianhydride (BPDA), react at 25°C for 1 hour, and then heat at 75°C for 25 hours to obtain The obtained polyamic acid solution (solid content concentration: 20 wt %) had a solution viscosity of 160 Pa·s. Added 0.832 g (0.2 molar equivalent to 1 molar equivalent of polyamic acid unit) of 2-methylimidazole as an imidation catalyst to the obtained polyamic acid solution, and 2.32 g (to 1 molar equivalent of polyamic acid unit) Amic acid unit is 0.2 molar equivalent) of benzoic anhydride as a dehydrating agent.

[0086] 20 parts by weight of polypropylene glycol with a weight average molecular weight of 400 was added to the polyamic acid solution to 100 parts by weight of the polyamic acid solution, followed by stirring to obtain a...

Embodiment 2

[0088] In Example 1, the polyimide porous body was produced by the method similar to Example 1 except having added the polypropylene glycol with a weight average molecular weight of 250 instead of the polypropylene glycol with a weight average molecular weight of 400.

Embodiment 3

[0090] In Example 1, 1.308 g (0.2 molar equivalent to 1 molar equivalent polyamic acid unit) of isoquinoline was added instead of 2-methylimidazole as an imidization catalyst, and poly A polyimide porous body was produced in the same manner as in Example 1 except that propylene glycol was used instead of polypropylene glycol having a weight average molecular weight of 400.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| relative permittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com