Roll cooling method for rolling of composite metal and special cooling device

A composite metal material and cooling method technology, which is applied in the field of composite metal material processing equipment, can solve problems affecting the composite effect of two metals, and achieve the effects of improving the composite effect of metal materials, good cooling effect, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

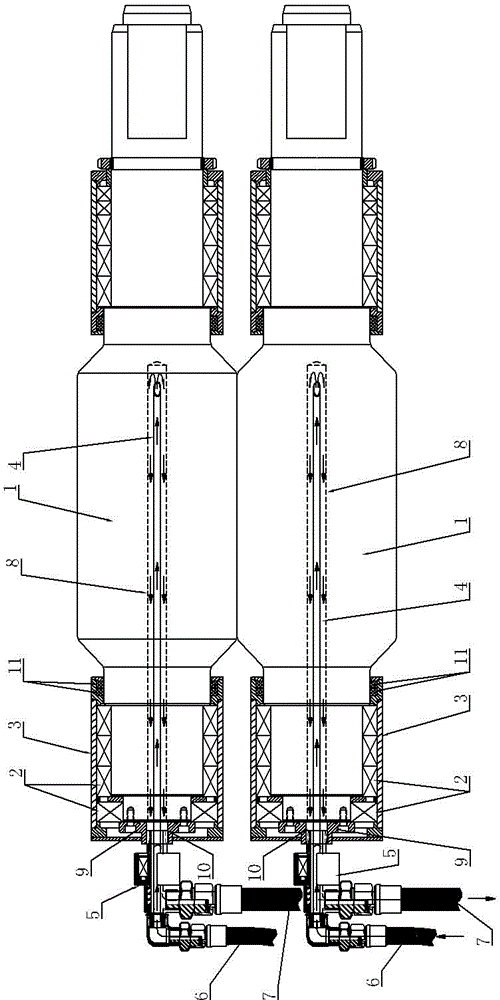

[0015] A roll cooling method for rolling composite metal materials, in which a blind hole channel is respectively set up on the upper and lower rolls of the rolling mill along the central axis of the roll, and a cooling water pipe with an outer diameter smaller than the inner diameter of the blind hole channel is arranged in the blind hole channel to Cooling pressure water is passed into the cooling water pipe, and the cooling pressure water flows out from the end of the cooling water pipe at the bottom of the blind hole channel and returns from the area between the outer wall of the cooling water pipe and the inner wall of the blind hole channel to take away the heat of the roll. Water temperature ≤ 30°C; flow rate of cooling pressure water is 6.0 m 3 / h ~7.0m 3 / h; The water pressure of the cooling pressure water is controlled by the water supply pump, and the working pressure of the water supply pump is 0.5 Mpa ~ 0.55Mpa.

[0016] See figure 1 , a roll cooling device for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com