Method and device for adsorption and separation of sheet material and available cutting waste material

A technology for cutting waste and separating devices, which is applied in the direction of feeding devices, positioning devices, storage devices, etc., which can solve the problems of material waste and inability to realize waste recycling, so as to ensure operating efficiency, realize profit margin growth, and improve material utilization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

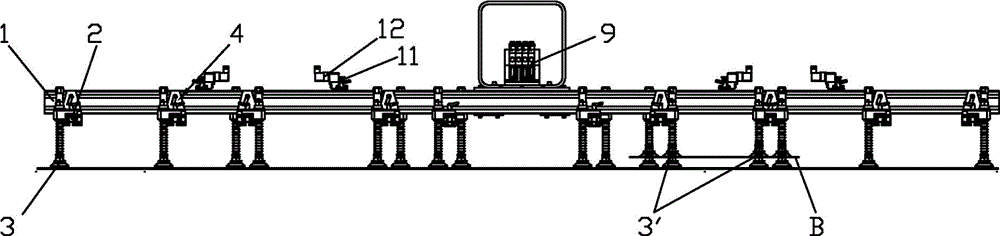

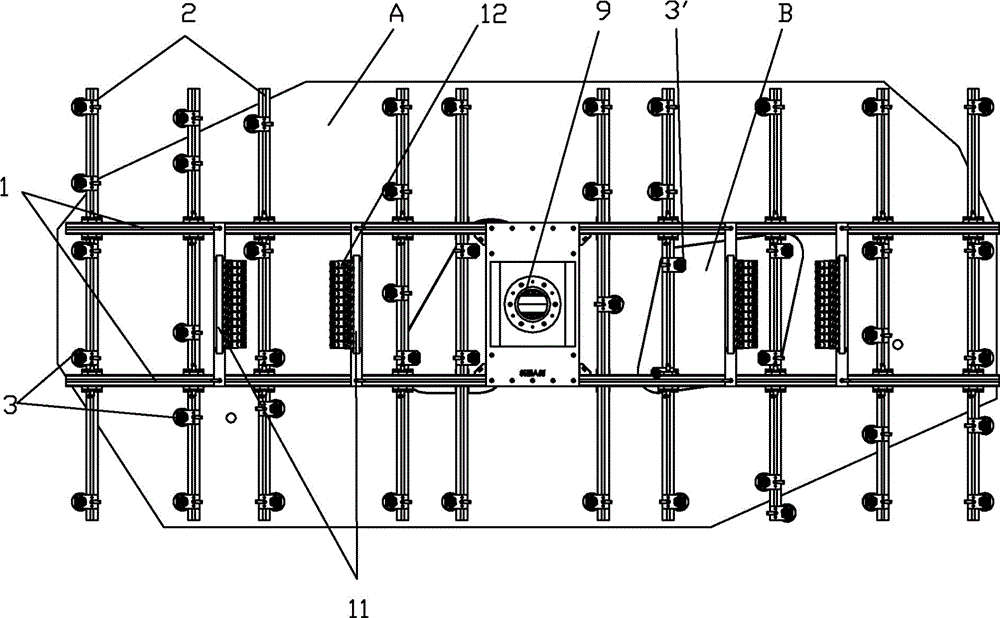

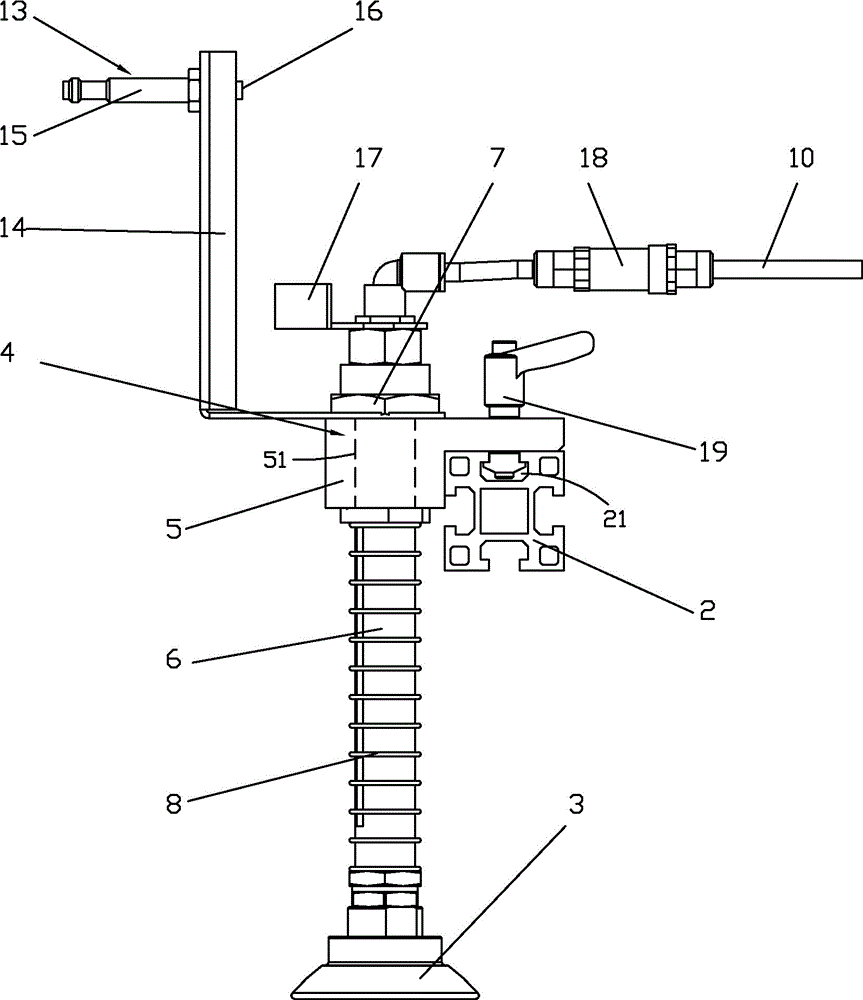

[0024] see Figure 1 ~ Figure 4 , the adsorption and separation device for flakes and usable cutting waste of the present invention comprises two main beams 1 arranged in parallel; several auxiliary beams 2 arranged in parallel under the main beam 1 and connected with the main beam The beam 1 is vertical; several suction cups 3, 3' are installed on the auxiliary beam 2, corresponding to the piece A and the usable waste B, and are arranged between the suction cups 3, 3' corresponding to the piece A and the usable waste B A height difference; the suction cup support structure 4 corresponds to each suction cup 3 (take the suction cup 3 as an example, the same below), which includes a fastening block 5, one side of which is arranged on the auxiliary beam 2, and the other side There is a through hole 51 that runs up and down; the spring strut 6, the upper part of which is passed through the through hole 51 of the fastening block, and is limited by the nut 7; the suction cup 3 is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com