Glare-proof light emitting device

A light-emitting device and anti-glare technology, applied in the field of lighting, can solve the problems of limited irradiation distance, large volume and heavy weight of the reflector, and achieve the effect of small lens size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

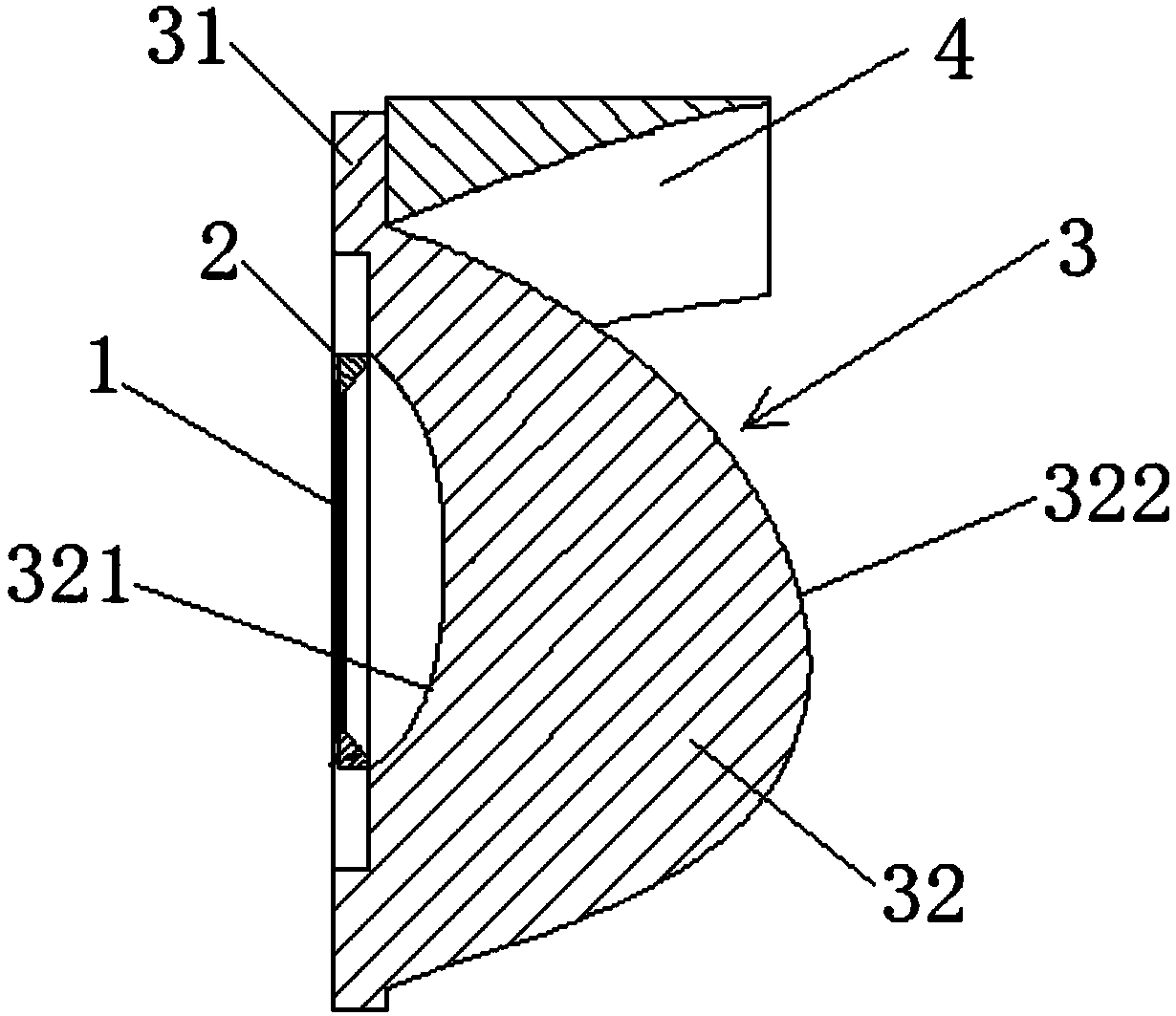

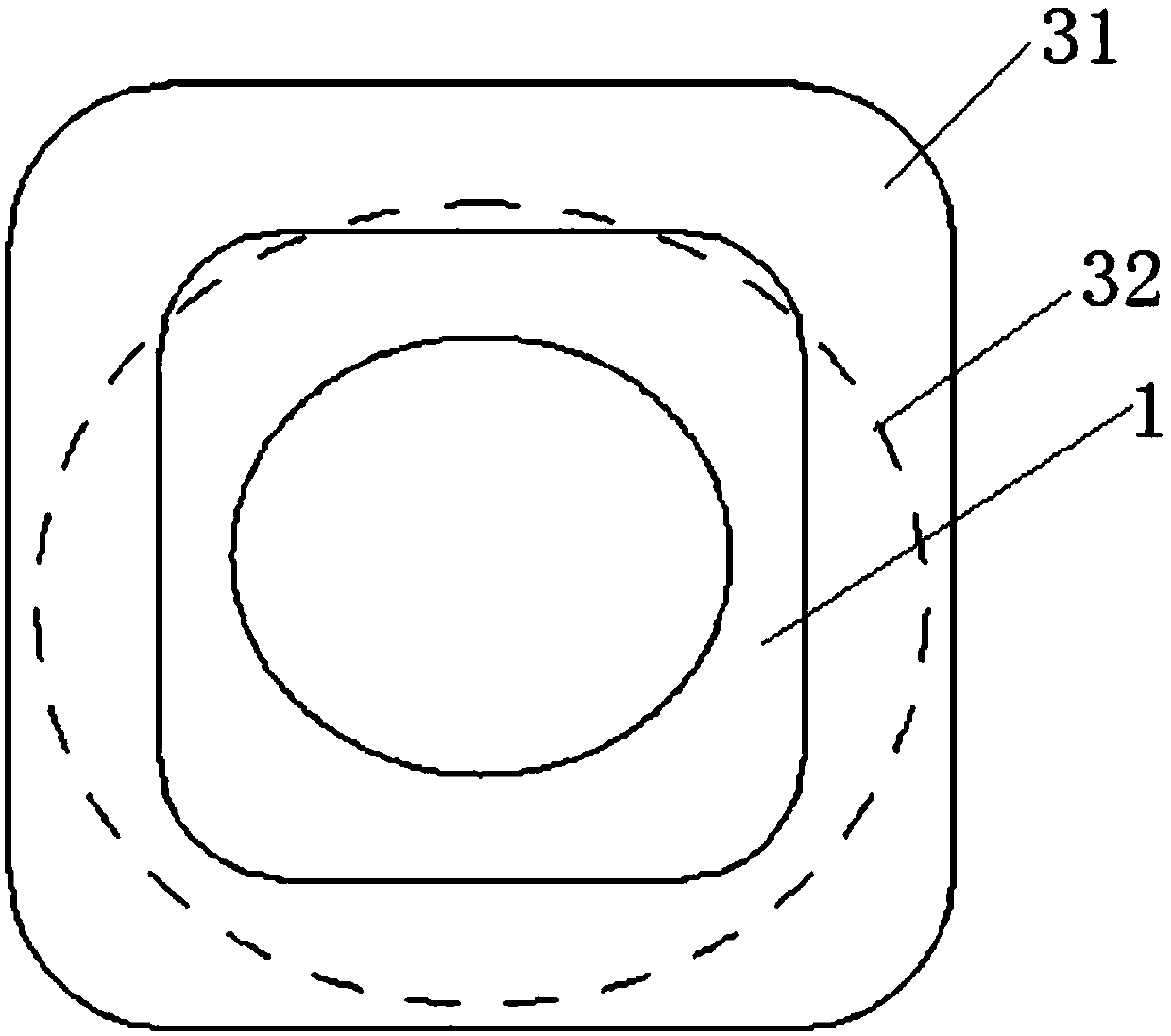

[0025] This embodiment provides an anti-glare lighting device, such as Figure 1-2 As shown, the light emitting device includes a light source 1, a reflective washer 2, a polarizing lens 3 and a specular reflector 4 connected in sequence, wherein the light source 1 is a COB light source, the reflective washer 2 is a plastic washer, and the mirror surface The reflector 4 can be made of plastic or optical glass, and its surface is coated with a layer of anti-corrosion and high reflectivity. Most of the light emitted by the light source 1 enters the polarizing lens 3. The large-angle light at the edge of the light source 1 enters the polarizing lens 3 after being reflected by the reflective gasket 2. The polarizing lens 3 collects the light and distributes the angle of the refracted light. The light emitted by the polarizing lens 3 is reflected by the inner surface of the mirror reflection component 4 to make the angular direction of the light consistent with the angular directio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com