Self-heat-insulation flexible interlayer air duct for tunneling roadway or vertical shaft

A technology for shafts and tunnels, which is applied in the improvement field of self-insulating flexible interlayer air ducts, which can solve the problems of inability to guarantee the comfort of the deep environment, the deviation of the cold air temperature from the design temperature, and uneconomical conditions, so as to achieve the best thermal insulation effect and improve work efficiency. The effect of efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

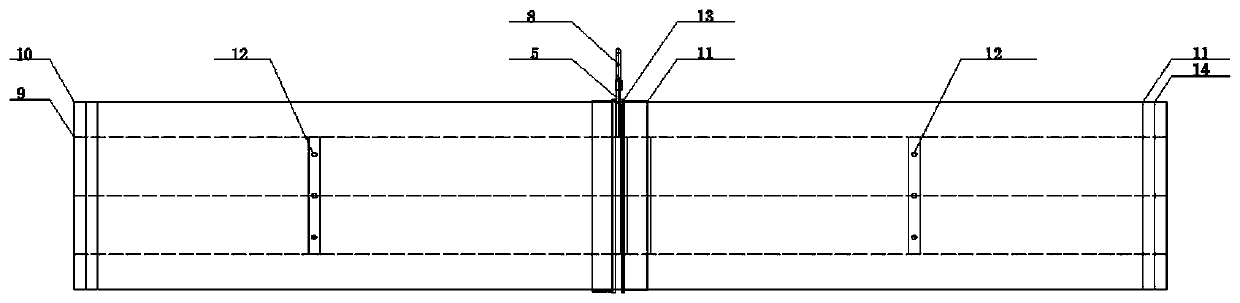

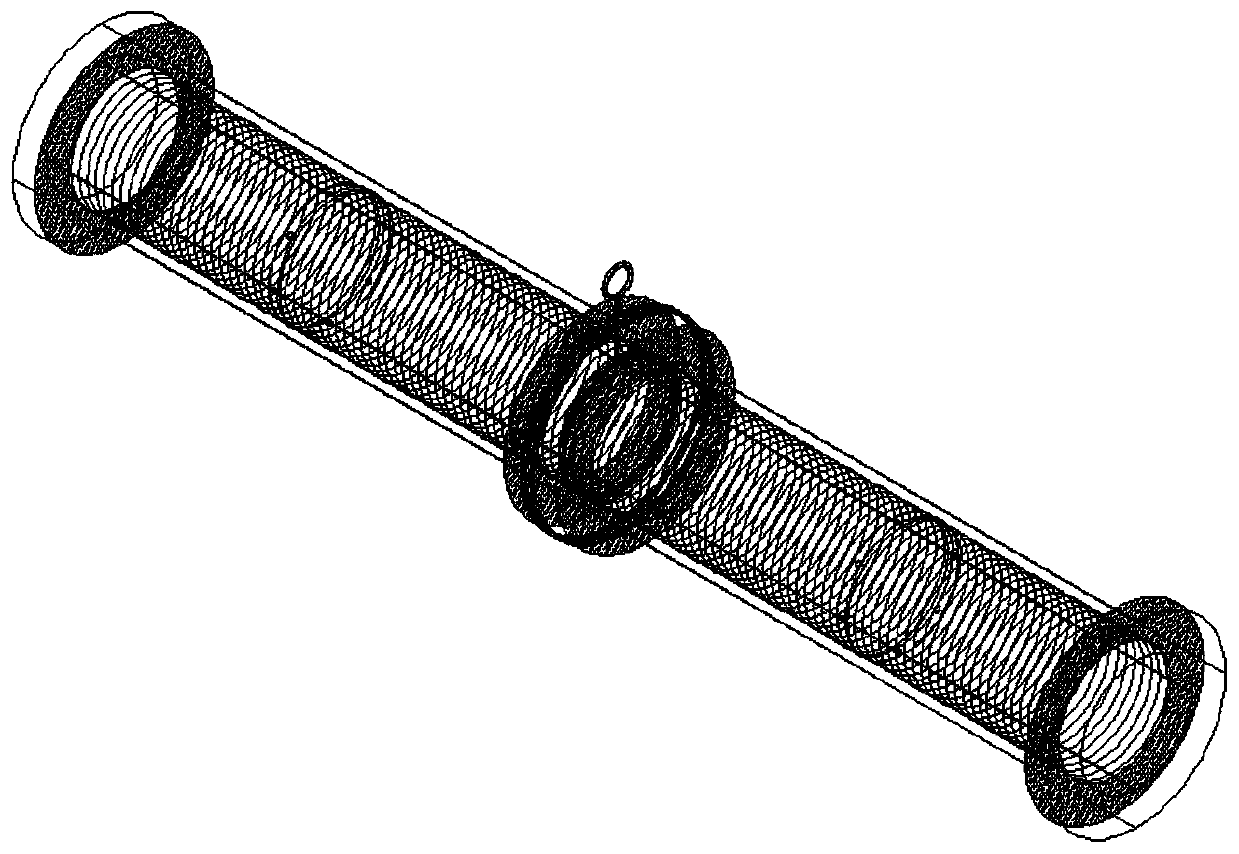

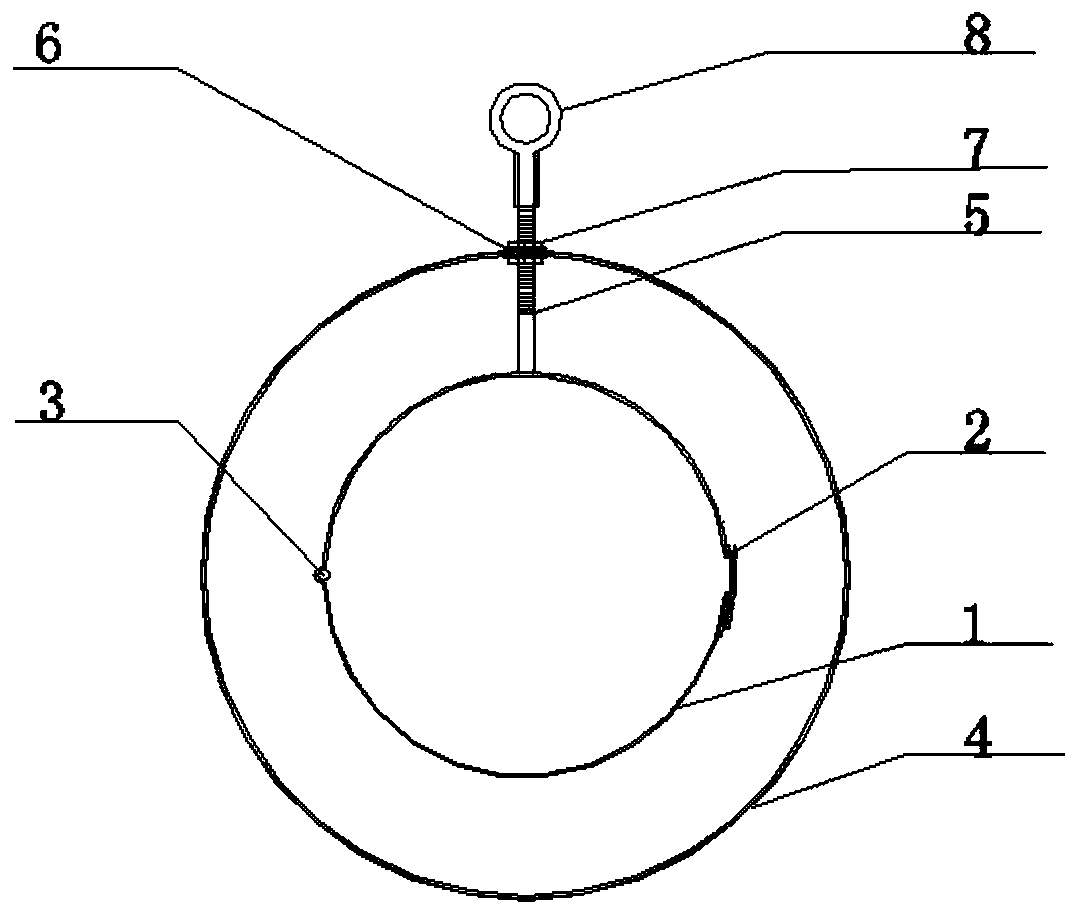

[0027] reference Figure 1-5 , The present invention provides the following technical solutions: a self-insulating flexible interlayer air duct for roadway or shaft excavation, including its main structure and connecting parts. The main structure consists of an inner air duct 9, an outer air duct 10 and an annular interlayer 11 The two ends of the air duct are overlocked with fixed iron rings 14, and the middle of the inner air duct is provided with eight vent holes 12 evenly arranged in a circumferential direction, which is convenient for inflating the interlayer space. The edges of the vent holes 12 are clamped by metal sheets. Prevent the hair dryer cloth from tearing. The annular inter-cloth 11 includes a head-end inter-cloth and a tail-end inter-cloth. The inner ring of the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com