Using method of cloth rolling machine feeding strip

A technology of advancing strips and cloth winding machines, which is applied in the directions of winding strips, thin material processing, transportation and packaging, etc. It can solve the problems of difficult removal of residues on the surface of the rolling wheel, reduction of working efficiency of the cloth winding machine, and difficulty in advancing the effect, etc. problem, to achieve the effect of novel design ideas, good promotion effect, economical and practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

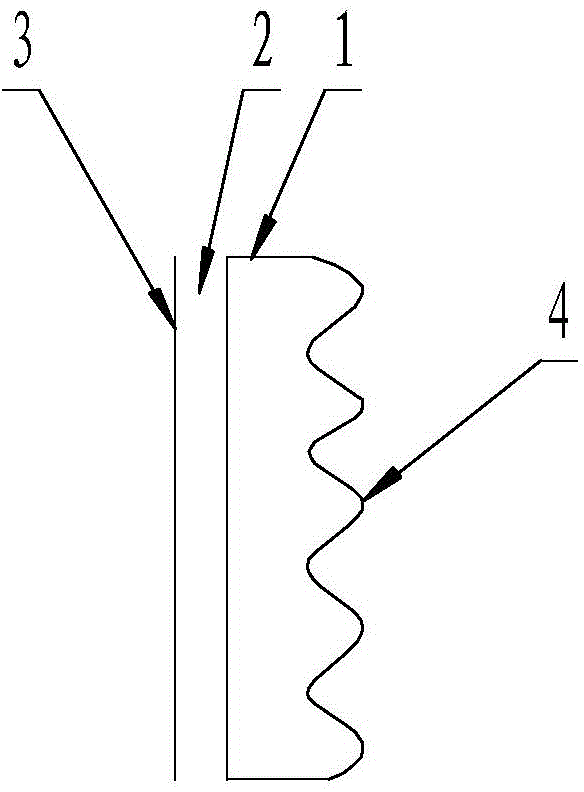

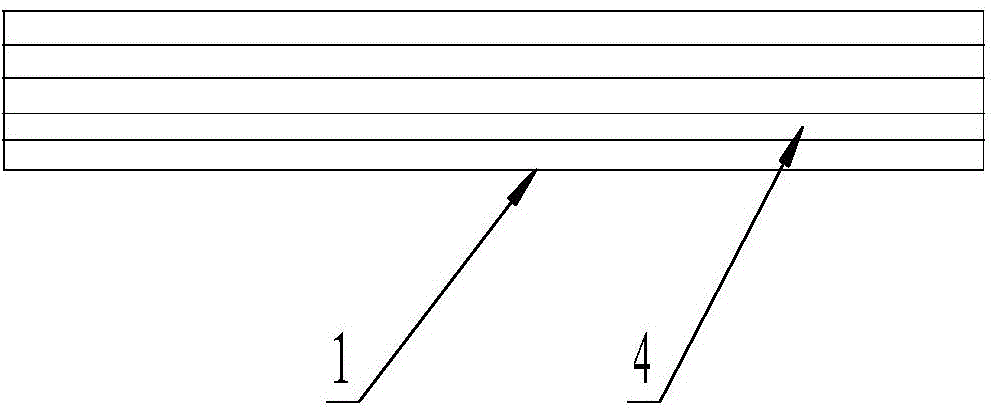

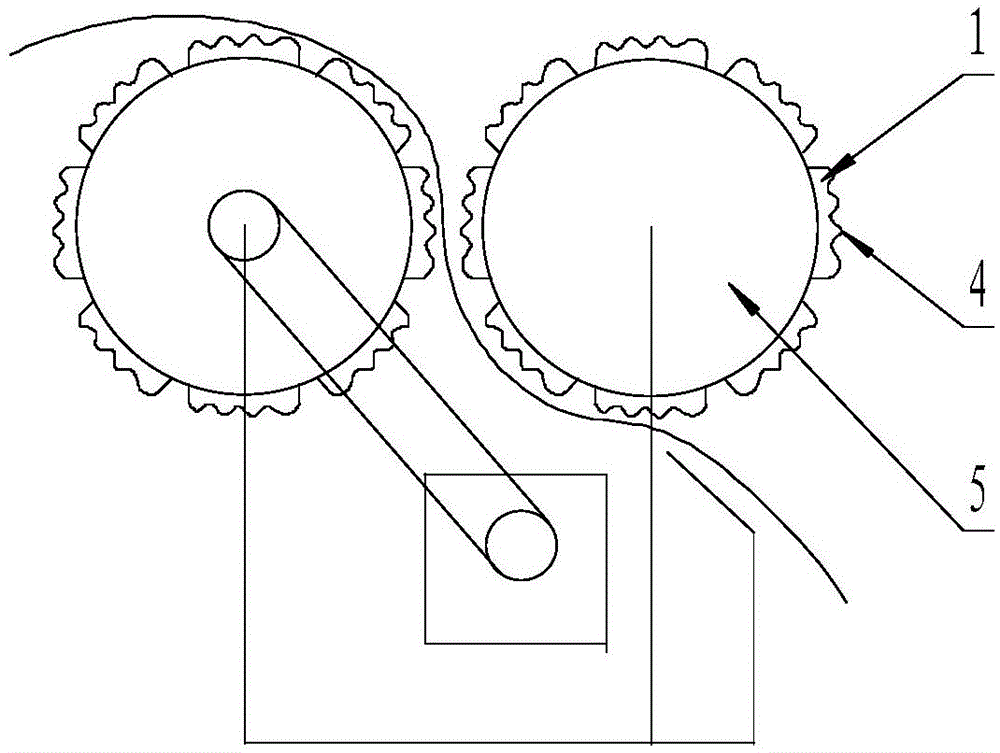

[0020] Remove the sticker 3 on the back of the push bar, and glue the adhesive layer 2 on the back of the bottom plate 1 corresponding to the roll 5. The cloth passes between the two rolls 5, and the motor drives the roll 5 to rotate. Driven by the friction force, the cloth can be conveyed at a uniform speed.

Embodiment 2

[0022] Adjust the distance between the two rolls 5 according to the cloth of different materials to obtain the required frictional force.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com