A d-a2/o wastewater treatment reactor with alternate two-phase anaerobic and anoxic operation

An alternate operation, D-A2 technology, applied in biological water/sewage treatment, water/sludge/sewage treatment, aerobic and anaerobic process treatment, etc. The effect of improving and saving operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

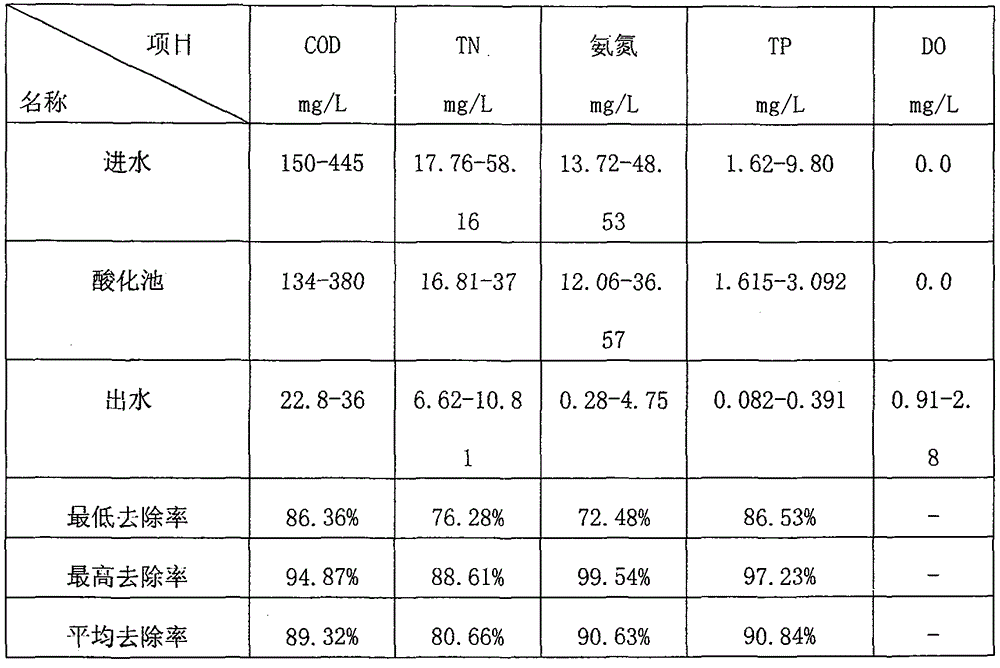

[0027] Below in conjunction with specific embodiment, further describe the present invention.

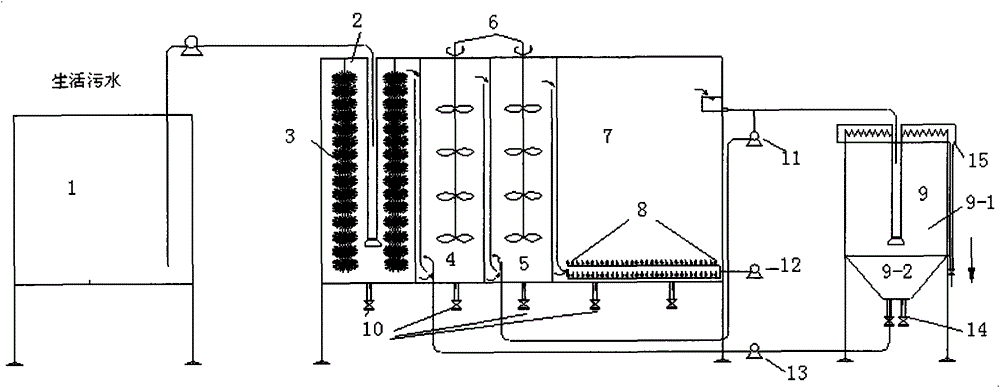

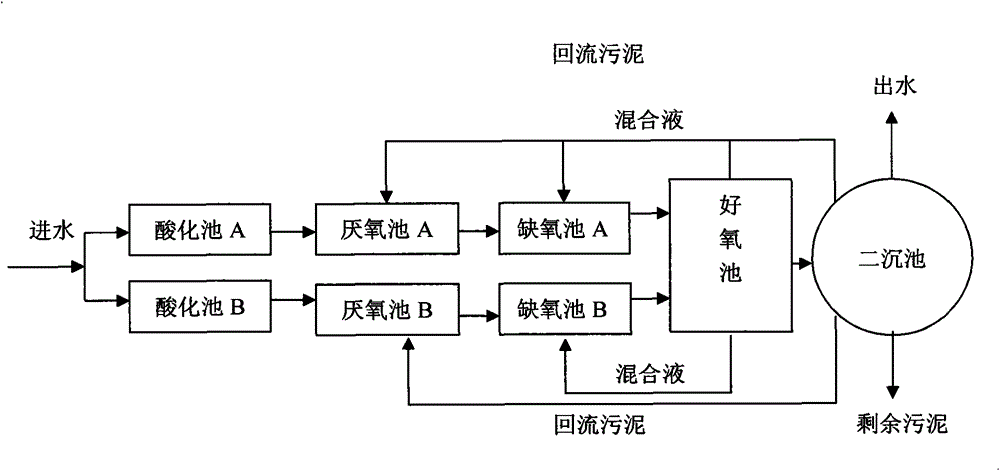

[0028] A two-phase anaerobic-anoxic alternating operation D-A 2 O sewage treatment reactor, it is characterized in that comprising water tank 1, acidification pond 2, anaerobic pond 4, anoxic pond 5, aerobic pond 7 and secondary settling pond 9, the domestic sewage in described water tank 1 passes through acidification successively by pump Pond 2, anaerobic pond 4, anoxic pond 5, aerobic pond 7 and secondary settling pond 9 obtain clean water from water outlet 15, and sludge is discharged by the sludge outlet 14 of secondary settling pond 9.

[0029]The acidification tank 2 has a suspended film-hanging filler 3, the anaerobic tank 4 and the anoxic tank 5 both have an agitator 6, and the aerobic tank 7 has an aeration head 8.

[0030] There is a mixed liquid return pump 11 between the aerobic tank 7 and the anoxic tank 5, and the return liquid is returned to the anoxic tank 5; there...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com