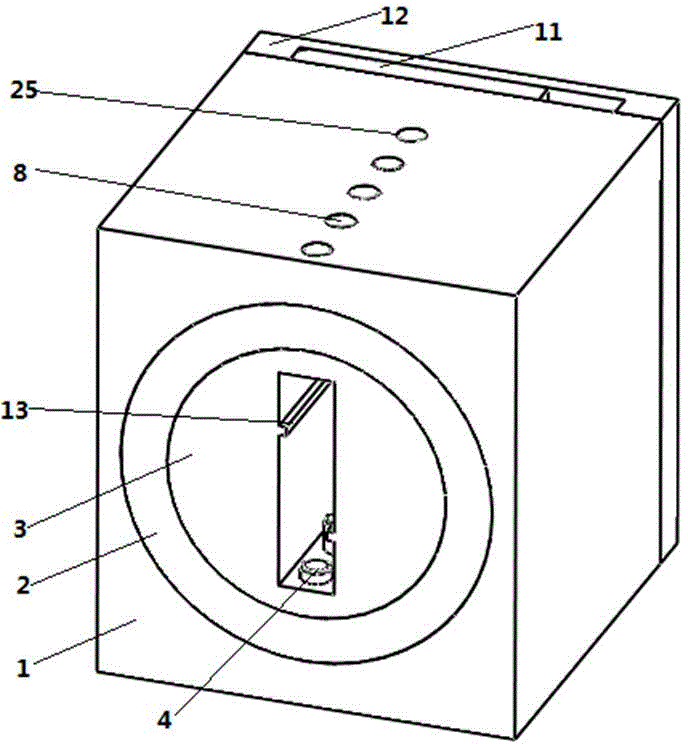

Mechanical spring lock of helicopter control cabinet

A technology for control cabinets and helicopters, applied to cylinder locks, locks with turning keys, building locks, etc., can solve the problems of lengthening maintenance and repair cycles, increasing keys, and difficult management, so as to save production cycle and save development cost, ease of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

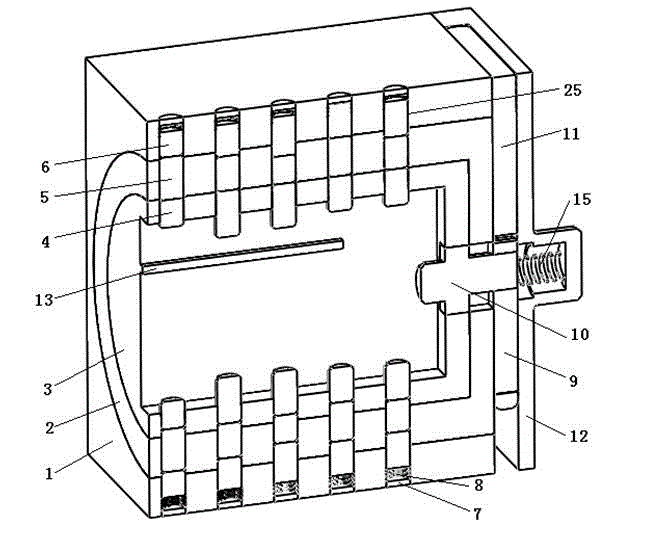

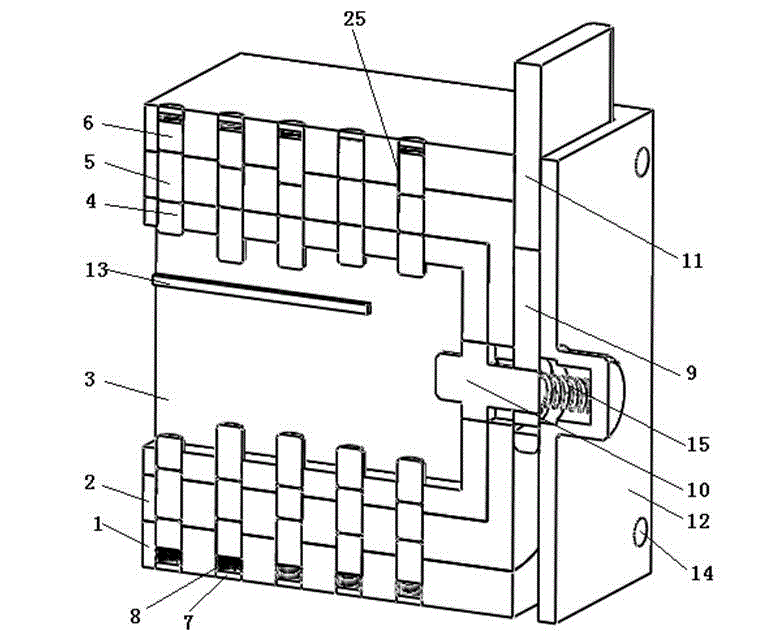

[0075] see Figure 6 , the driver inserts the key 18 into the flat square long counterbore of the inner lock core 3, the arc edge of the front section is in axial contact with the ejector rod 9, and the ejector rod double-headed key 20 of the ejector rod 9 is connected to the inner lock core 3 In the inner lock core double key hole 22. The bottom edge of five pairs of grooves on both sides of the front section of the driver's key 18 is respectively in contact with one end face of five pairs of inner layer pins 4 of the inner lock core 3, and the other end face of the five pairs of inner layer pins 4 is respectively in contact with the middle layer lock. One end face of the five pairs of pins 5 in the middle layer of the core 2 is in contact with the upper and lower busbars of the cylinder of the inner lock core 3, and the radial connection between the cylinder of the inner lock core 3 and the oblong counterbore of the middle lock core 2 completely disengaged. And or middle l...

Embodiment 2

[0079] see Figure 7 , the maintenance personnel inserts the key 19 into the flat square long counterbore of the inner lock cylinder 3, and the arc-shaped raised edge of the front section pushes the ejector rod 9 to move axially, so that the compression spring 15 at the rear end of the ejector rod 9 is compressed, and the ejector rod The push rod double key 20 of 9 breaks away from the inner lock core double key hole 22 of the inner lock core 3 and is keyed in the middle layer lock core double key hole 23 of the middle layer lock core 2 . The five pairs of groove bottoms on both sides of the front section of the key 19 are used by maintenance personnel to contact with one end faces of the five pairs of inner layer pins 4 of the inner lock core 3 respectively, and the other end faces of the five pairs of inner pins 4 are respectively in contact with the middle layer lock. One end faces of the five pairs of middle layer pins 5 of the core 2 are correspondingly in contact with ea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com