Bidirectional protection lubricating wear-resistant coupling

A wear-resistant agent and sucker rod coupling technology, applied in drilling equipment, earthwork drilling, drill pipe, etc. Good stability and thermal stability, good mechanical stability, low lubricating friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

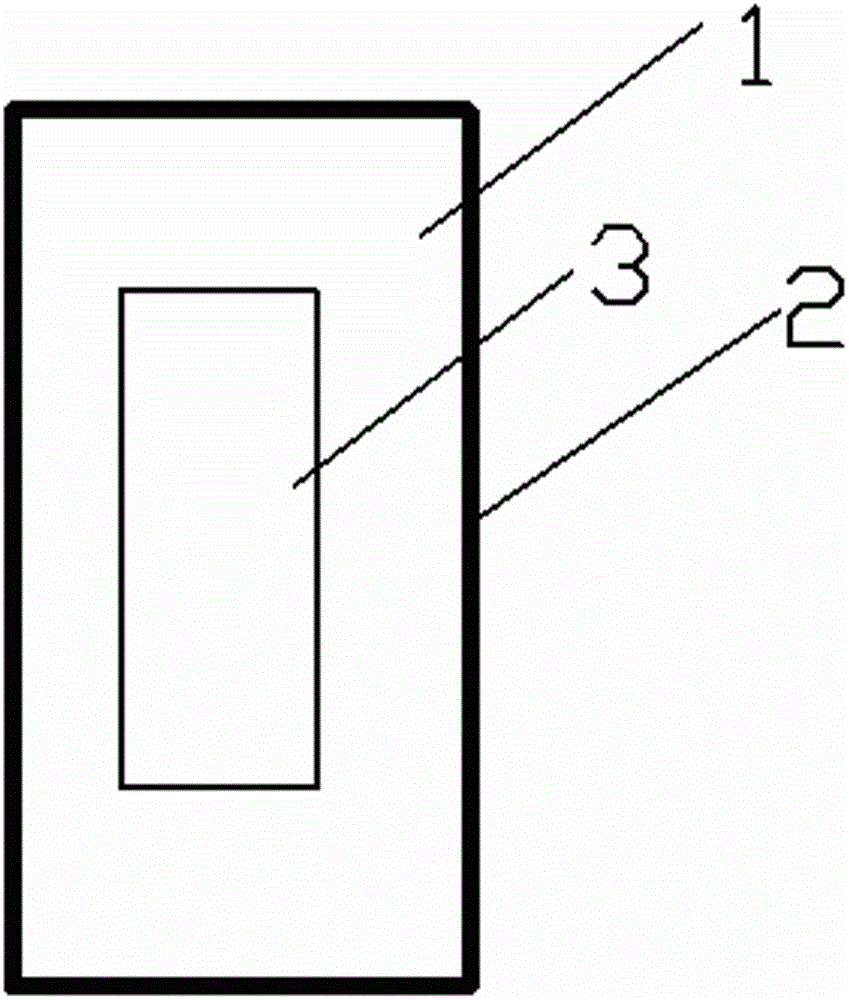

[0014] Below in conjunction with accompanying drawing, content of the invention will be further described:

[0015] refer to figure 1 As shown, a two-way protection lubricating and wear-resistant coupling includes coating a lubricating and wear-resistant agent on the surface of the sucker rod coupling 1 through a surface strengthening treatment process to form a lubricating and wear-resistant agent layer 2, and the lubricating and wear-resistant agent layer The thickness of 2 is less than 0.5mm. The lubricating and wear-resistant agent includes anti-corrosion agent, MoS2 and high-efficiency adhesive. The weight percentage of the anti-corrosion agent in the lubricating and wear-resistant coating agent ranges from 10% to 13%. The weight percentage of the MoS2 in the lubricating and wear-resistant coating agent ranges from 20% to 25%, and the weight percentage of the high-efficiency binder in the lubricating and wear-resistant coating agent ranges from 15% to 20%. Described pres...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com