Releasing tool

The technology of a hand-off tool and a core tube, which is applied in the field of hand-off tools, can solve the problems that affect the normal hand-off take-back pipe column back-connection work, the operation of forward-rotation hand-off is complicated, and the forward-rotation hand-off cannot be completed, so as to avoid unnecessary Stability factor, reduced construction risk, simple assembly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

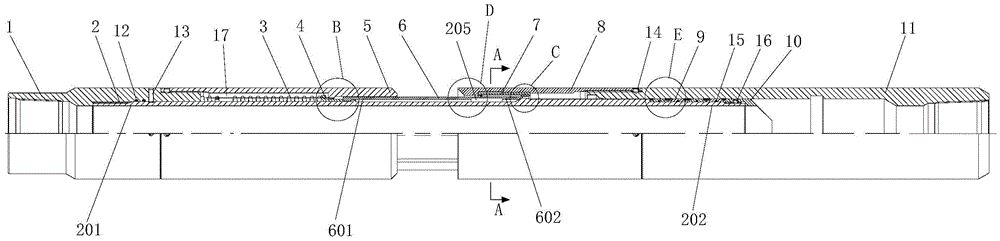

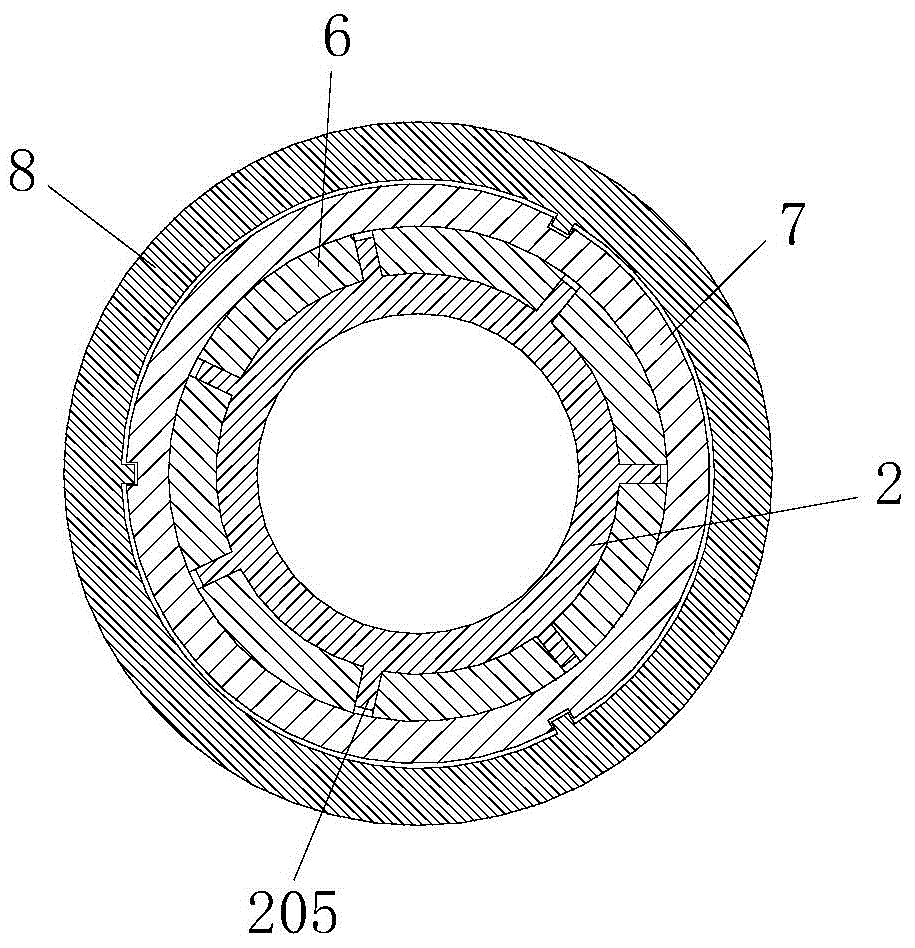

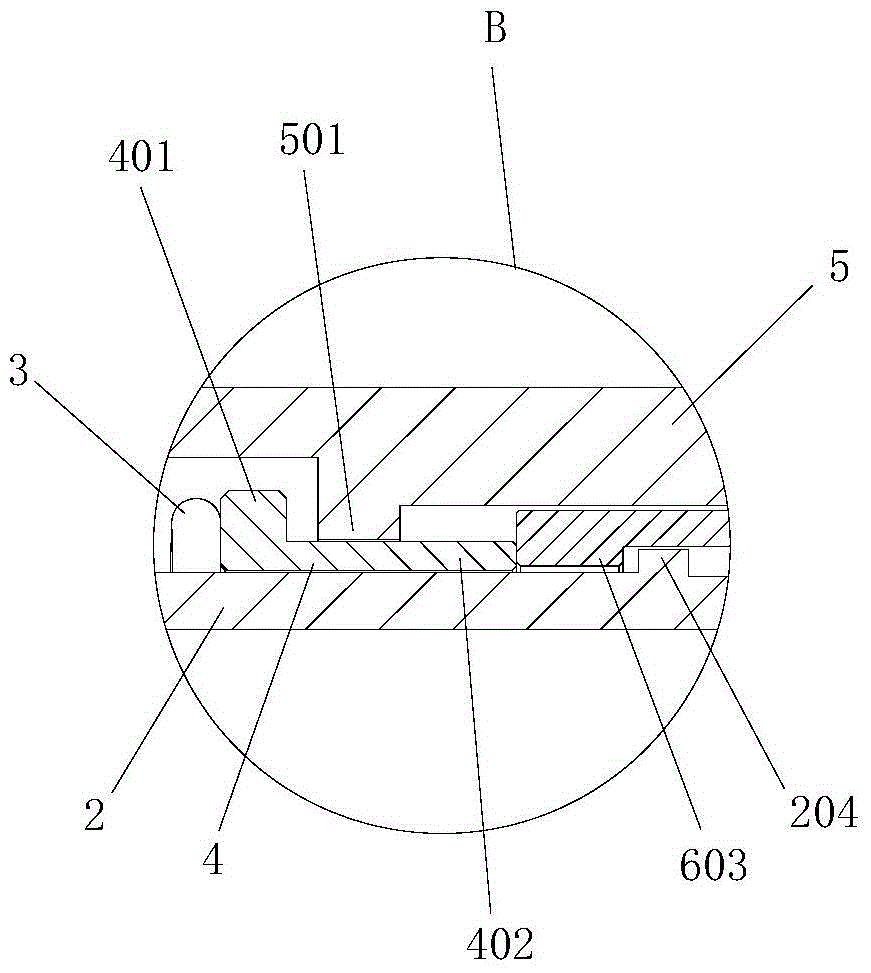

[0028] figure 1 It is a half-sectional view of the structure of the hand tool of the present invention, figure 2 for figure 1 A-A sectional view of, image 3 for figure 1 Enlarged view of Part B, Figure 4 for figure 1 Enlarged view of part C of Figure 5 for figure 1 Enlarged view of Part D, Image 6 for figure 1 Enlarged view of part E. Such as Figure 1 to Figure 6 As shown, a hands-free tool includes an upper assembly and a lower assembly. The upper assembly includes a joint 1, a core tube 2, a spring 3, a top sleeve 4, a connecting cylinder 5, slips 6, a sealing device 9 and a guide shoe. 10. The lower assembly includes a female locking ring 7, a limiting cylinder and a sealing cylinder; the core tube 2 includes a first end 201 and a second end 202, and the first end 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com