Planet half-shaft gear gasket

A half shaft gear and gasket technology, applied in belt/chain/gear, gear vibration/noise attenuation, components with teeth, etc., to achieve the effect of low friction, guaranteed service life and low noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

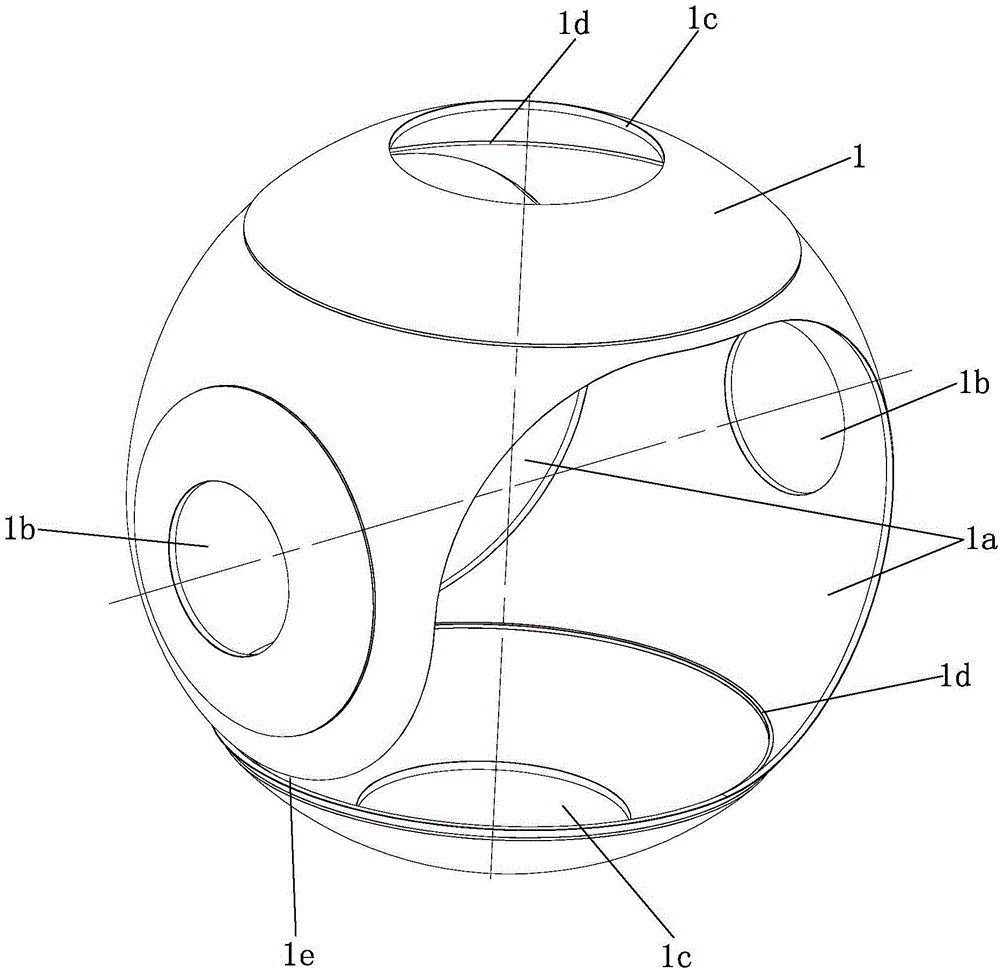

[0016] Such as figure 1 As shown, a planetary side gear gasket includes a gasket body 1, and the gasket body 1 is in the shape of a spherical shell. Moreover, the material of the gasket body 1 is a mature synthetic plastic, its grade is AROG6, and its composition is PA66+30% glass fiber. This material has both certain rigidity and certain elasticity.

[0017] A pair of workpiece passing openings 1a, a pair of small holes 1b and a pair of large holes 1c are opened on the gasket body 1, wherein the workpiece passing opening 1a is a circular structure, and the size of the large holes 1c is between the workpiece passing openings. 1a and the small hole 1b, and the line connecting the center of the pair of workpieces through the opening 1a passes through the center of the gasket body 1 .

[0018] There are two annular steps 1d on the inner wall of the gasket body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com