Manufacturing method of chip inductor, and chip inductor manufactured by manufacturing method

A manufacturing method and technology of chip inductors, applied in the direction of inductor/transformer/magnet manufacturing, transformer/inductor components, preventing/reducing unwanted electrical/magnetic effects, etc., can solve the problem of high frequency and ultra-miniaturization Insufficient inductance, inability to meet the requirements of small volume and high inductance, low magnetic permeability of chip inductance, etc., to achieve the effect of improving compression molding effect, low loss, good dispersion and adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

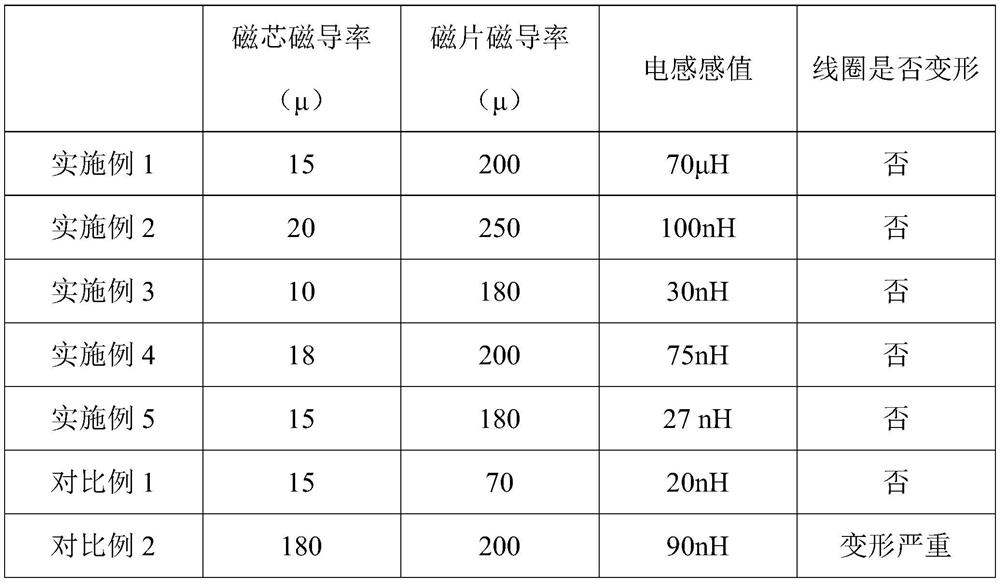

Embodiment 1

[0118] This embodiment provides a method for manufacturing a chip inductor, and the method includes the following steps:

[0119] (1) mixing the first phosphoric acid and alcohol to prepare the first passivation solution; adding the first passivation solution to the iron-silicon spherical powder (iron: 93.5wt%; silicon: 6.5wt%) whose particle diameter D50 is 15 μm, Stir and mix evenly, after the alcohol volatilizes, bake and heat at 150°C for 1.5h to obtain an insulating and coated spherical powder; the amount of the first phosphoric acid is 0.08% of the mass of the spherical powder, and the amount of alcohol is 4% of the mass of the spherical powder ;

[0120] Add the insulating coated spherical powder into bismaleimide polyimide thermosetting epoxy resin and acetone, mix and stir for 8 hours to obtain the first slurry with a viscosity of 150mPa·s; the amount of epoxy resin is 5% of the mass of the spherical powder after the treatment; the consumption of acetone is 12% of th...

Embodiment 2

[0133] This embodiment provides a method for manufacturing a chip inductor, and the method includes the following steps:

[0134](1) Mix the first phosphoric acid and acetone to prepare the first passivation solution; the first passivation solution is added to the spherical powder of sendust with a particle diameter D50 of 5 μm (iron: 85wt%; silicon: 9.6wt%; aluminum 5.4 wt%), stir and mix evenly, after the acetone volatilizes, bake and heat at 100°C for 0.5h to obtain a spherical powder after insulation coating; the amount of the first phosphoric acid is 0.05% of the mass of the spherical powder, and the amount of acetone is spherical powder 1% of powder mass;

[0135] Add the insulating coated spherical powder into bismaleimide polyimide thermosetting epoxy resin and acetone and mix for 12 hours to obtain the first slurry with a viscosity of 200mPa·s; the amount of epoxy resin is 8% of the processed spherical powder mass; the consumption of acetone is 15% of the insulating ...

Embodiment 3

[0147] This embodiment provides a method for manufacturing a chip inductor, and the method includes the following steps:

[0148] (1) Mix the first phosphoric acid and alcohol to prepare the first passivation solution; add the first passivation solution to the iron-nickel spherical powder (iron: 50wt%; nickel: 50wt%) with a particle diameter D50 of 30 μm, stir and mix Evenly, after the alcohol volatilizes, bake and heat at 230°C for 2 hours to obtain an insulating and coated spherical powder; the amount of the first phosphoric acid is 1% of the mass of the spherical powder, and the amount of alcohol is 6% of the mass of the spherical powder;

[0149] Add the insulating-coated spherical powder into bismaleimide polyimide thermosetting epoxy resin and acetone, mix and stir for 3 hours to obtain the first slurry with a viscosity of 10 mPa s; the amount of epoxy resin is 3% of the mass of the spherical powder after the treatment; the consumption of acetone is 5% of the mass of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com