Deformation honeycomb cellular structure kitchen table-board and preparing technique thereof

A technology of honeycomb structure and countertop, applied in lamination auxiliary operation, lamination device, lamination, etc., can solve problems such as cracking and deformation, and achieve the effects of improving pressure resistance, reducing dust pollution, and not reducing the overall strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

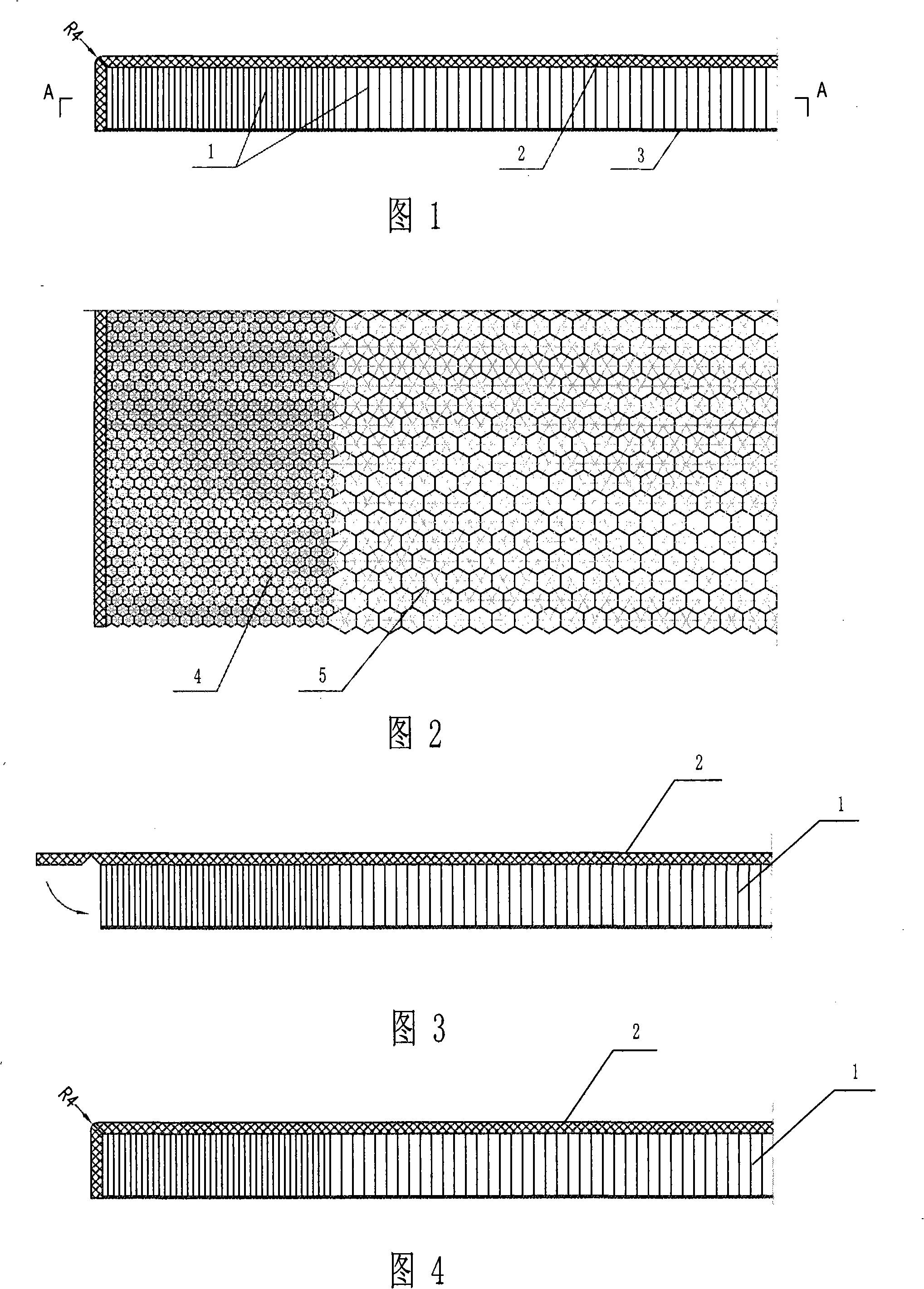

[0031] The deformed honeycomb structure kitchen countertop described in the present embodiment, as shown in Figure 1, on the deformed honeycomb panel (1), the artificial stone plate (2) is bonded as the surface layer, and under the deformed honeycomb panel (1), the balance layer ( 3), one side of which is integrally covered by the artificial stone plate (2) on the surface layer after hot-bending.

[0032] The side chamfering of the surface layer artificial stone plate (2) after heat bending is R4, and the thickness of the artificial stone plate (2) is 3-6 mm. The thickness of the artificial stone plate (2) in this embodiment is 6 millimeters.

[0033] As shown in Figure 2, the two sides of the deformed honeycomb panel (1) have a large honeycomb density and a small aperture; they respectively account for about 1 / 6 of the depth of the table; the middle part has a small density and a large aperture, accounting for about 2 / 3 of the depth of the table; The shapes of the honeycombs...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com