Rapid nondestructive testing method for permanent magnet material-based sub-quality product with poor room-temperature and high-temperature performances

A permanent magnet material and non-destructive testing technology, which is applied in the direction of magnetic performance measurement, etc., can solve the problems of high-temperature magnetic property inhomogeneity, heavy workload, and inconvenient convenience, and achieve the effect of fast detection process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

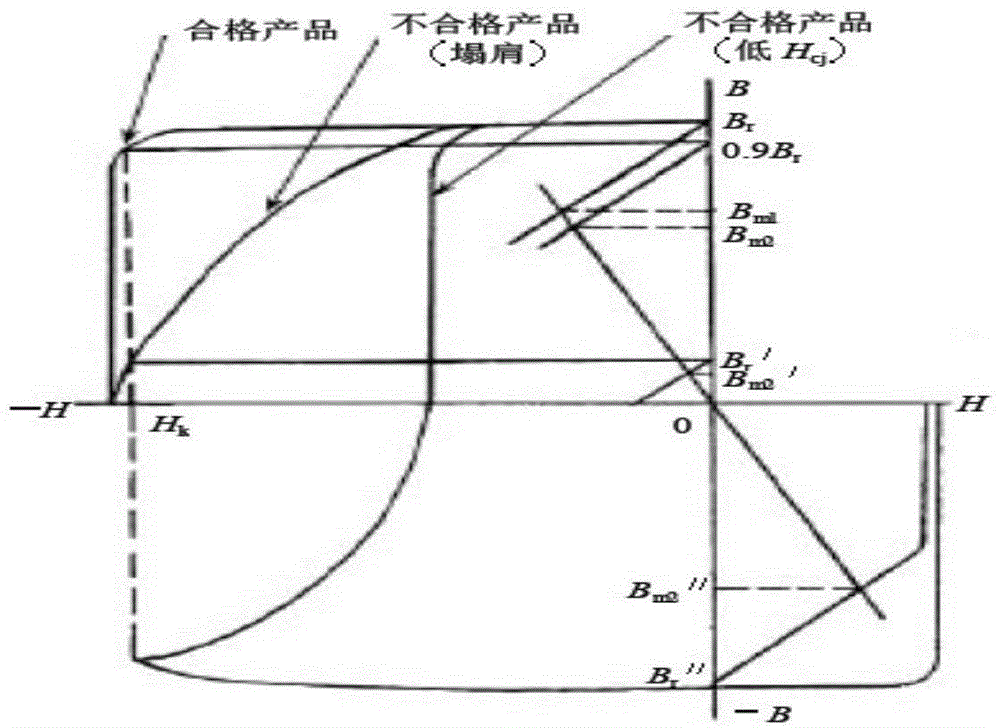

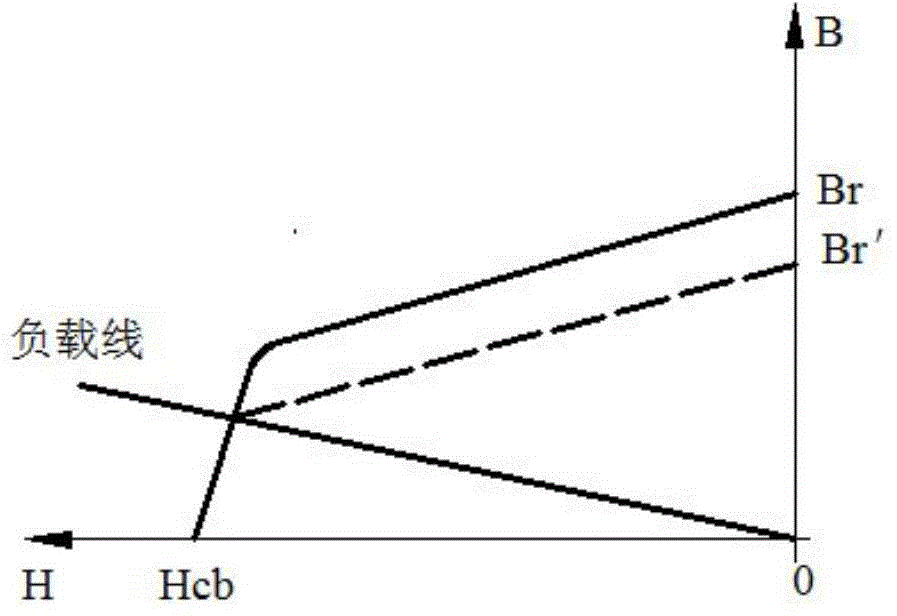

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Select a batch of NdFeB permanent magnet material samples of the same size for testing. The samples are rectangular magnets with a brand name of 40M, and saturate magnetization for all samples.

[0031] (2) Put the magnetized sample into the electromagnet, heat it to 100°C, and keep it warm for 10 minutes. Then apply 0.9 to the sample demagnetization of the demagnetization field. Finally, the demagnetized samples were taken out and cooled to room temperature.

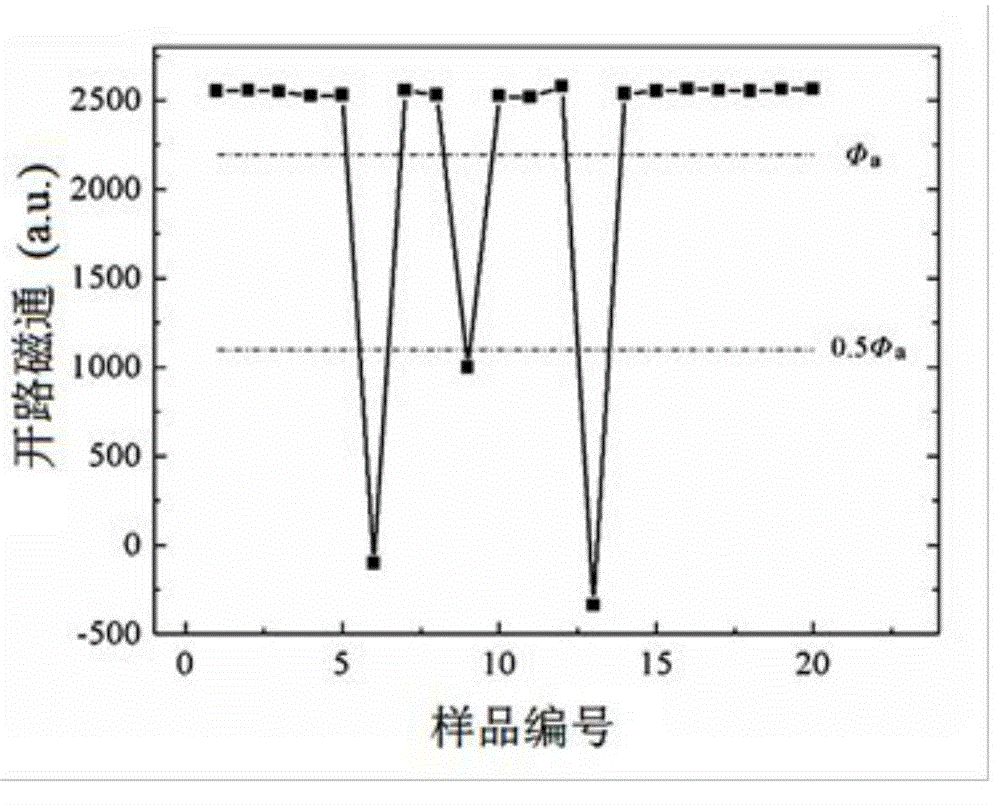

[0032] (3) Measure the open-circuit magnetic flux of each sample at room temperature, and the measurement results are as follows: image 3 As shown in the figure, Φs is the average magnetic flux of the sample, and the open-circuit magnetic flux of samples 6, 9, and 13 is obviously lower than that of other samples, which are unqualified samples.

[0033] Detect the intrinsic coercive force and magnetic energy product of 20 samples at room temperature and high temperature, such as Figure 4 with Figure 5...

Embodiment 2

[0035] The difference between this embodiment and Embodiment 1 is: ferrite

Embodiment 3

[0037] The difference between this embodiment and embodiment 1 is: AlNiCo

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com