Design method of furnace roll profile in furnace section of continuous annealing unit

A continuous annealing unit and roll shape design technology, applied in the field of metallurgical steel rolling, can solve problems such as roll shape optimization and qualitative analysis of unfurnished rolls

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

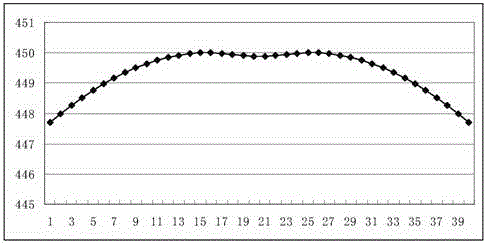

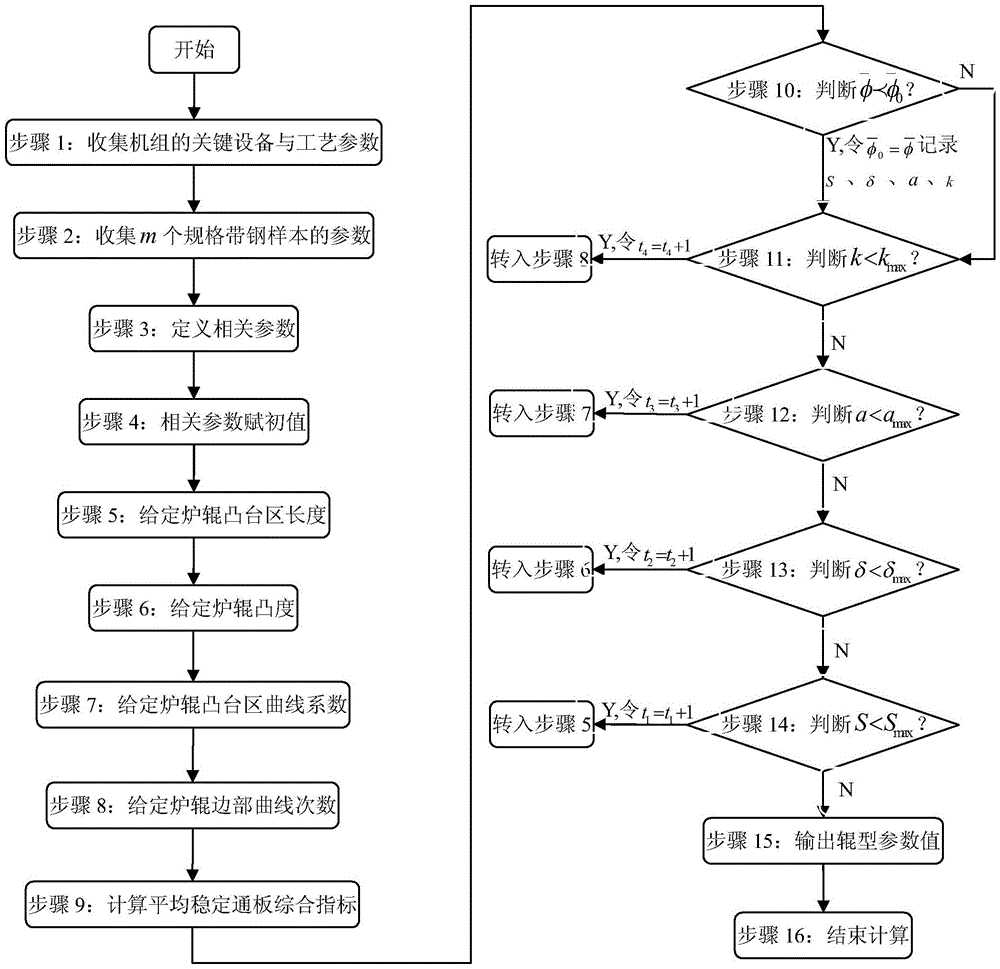

[0050] exist figure 1 In the general flowchart of the design method of the furnace roll profile of the continuous annealing unit shown, first, in step 1, collect the profile parameters of the furnace roll, mainly including: the maximum roll diameter of the furnace roll D=900mm, the length of the furnace roll body L =1950mm, furnace roller surface roughness Ra r1 =4.5μm;

[0051] Subsequently, in step 2, the process parameters of this process section are collected, mainly including: the set tension σ=6.5MPa, the set temperature T=750°C of the process section, and the indoor temperature T under normal conditions sw =25℃;

[0052] Subsequently, in step 3, heat transfer related parameters are collected, mainly including: furnace roll and strip heat transfer coefficient a 1 =2500W / m 2 ·℃, furnace roller and gas heat transfer coefficient a 2 =α B =50W / m 2 ·℃, furnace roller specific heat C p =460J / kg·℃, furnace roller thermal expansion coefficient β=12×10 -6 / °C, furnace ro...

Embodiment 2

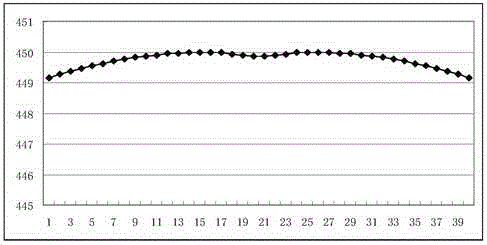

[0083] First, in step 1, collect the roll shape parameters of the furnace roll, which mainly include: the maximum roll diameter of the furnace roll D=900mm, the length of the roll body of the furnace roll L=1950mm, the surface roughness of the furnace roll Ra r1 =1.8μm;

[0084] Subsequently, in step 2, the process parameters of this process section are collected, mainly including: the set tension of the process section σ=7.3MPa, the set temperature T=720℃, the indoor temperature T under normal conditions sw =25℃;

[0085] Then, in step 3, the related parameters of heat transfer are collected, mainly including: heat transfer coefficient a between furnace roll and strip steel 1 =2500W / m 2 °C, heat transfer coefficient a between furnace roll and gas 2 =α B =50W / m 2 °C, specific heat of furnace roll C p =460J / kg·℃, thermal expansion coefficient of furnace roll β=12×10 -6 / ℃, thermal conductivity of furnace roll K=29W / m·℃ and furnace roll density ρ=7800kg / m 3 Wait.

[008...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com