Walnut shearing-extrusion shell-breaking, flexible-thrashing and kernel-taking equipment

A walnut kernel and shell breaking device technology, which is applied in the field of mechanical technology and equipment, can solve the problems of reducing the integrity rate of walnut kernels, the kernel yield rate, the performance index of breaking the shell and extracting kernels is low, and the effect is not ideal, so as to shorten the labor time, Reduce processing costs and avoid breaking effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention will be further introduced below in conjunction with the accompanying drawings and embodiments.

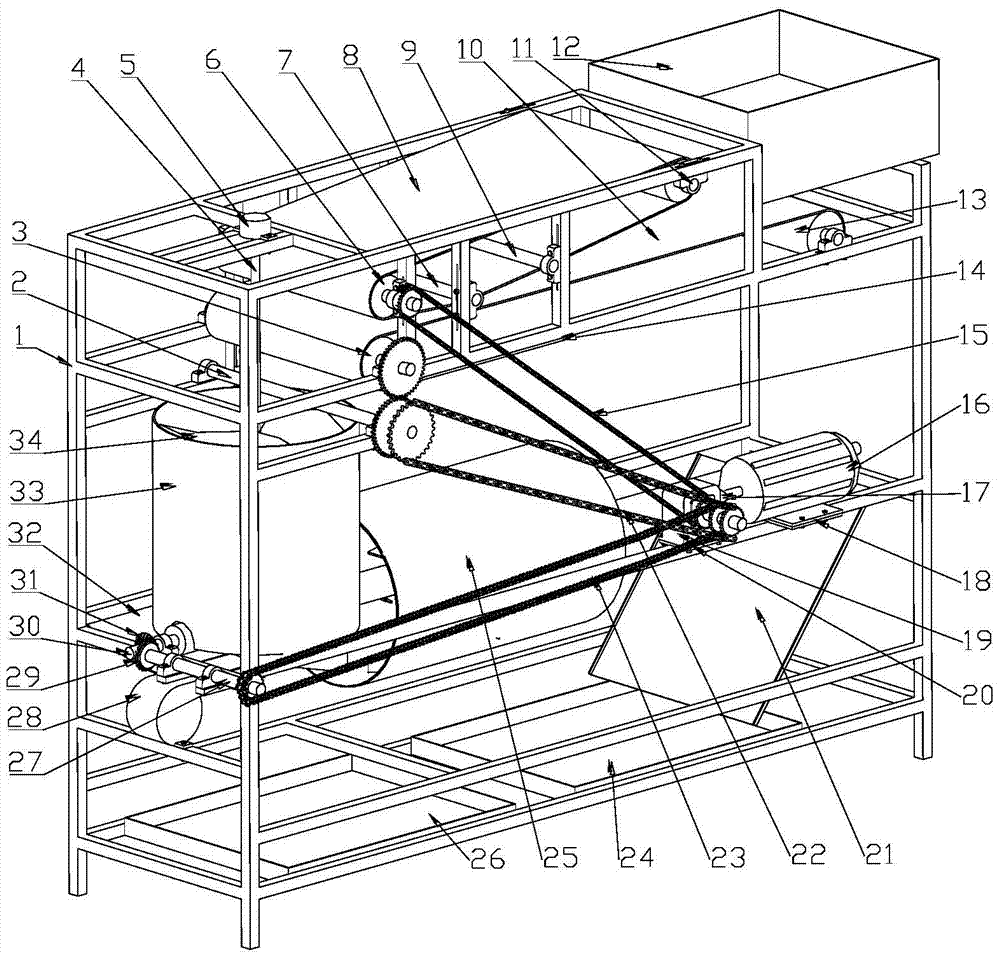

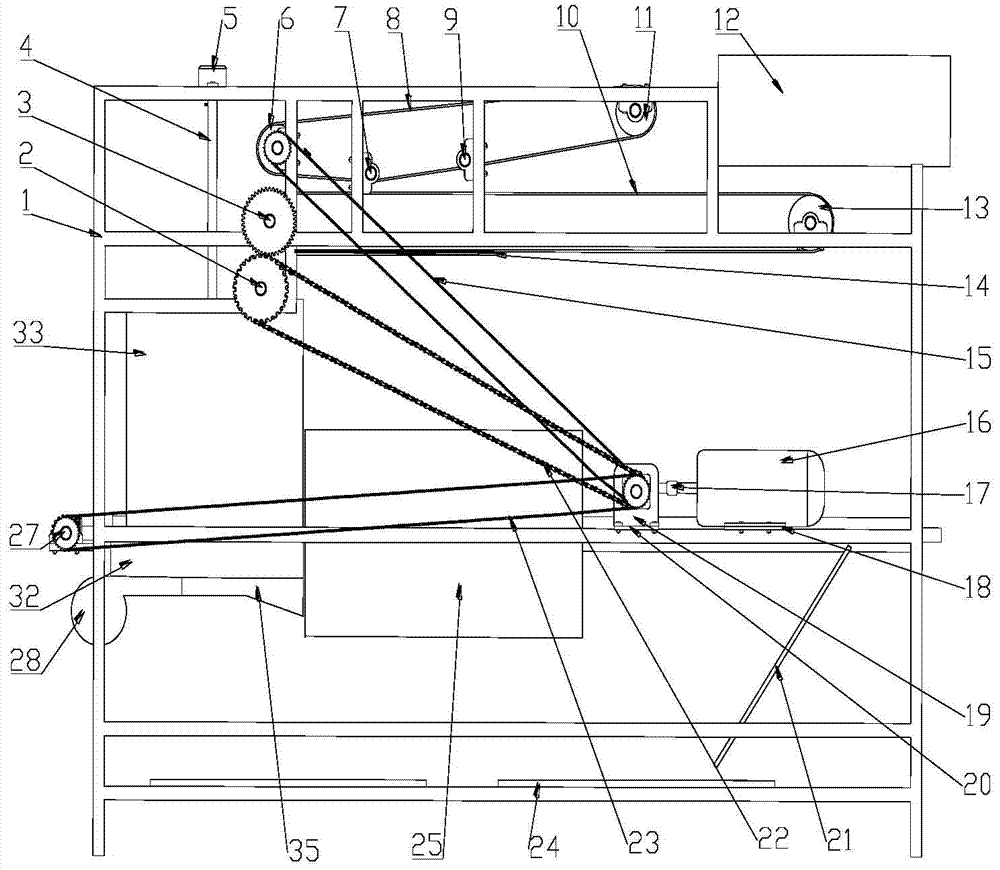

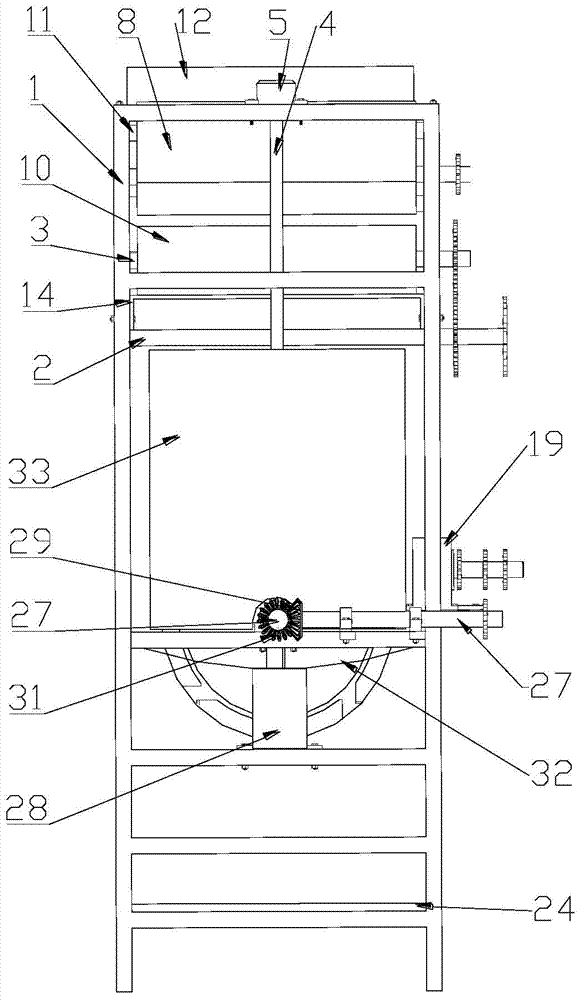

[0055] figure 1 It is the axonometric drawing of the whole equipment, including frame 1, transmission system, flat belt shearing extrusion shell breaking device, working flat belt height and tightness adjustment device, flexible helical blade hammering system and separation device.

[0056] Said frame 1 is a structure for fixedly connecting and assembling the parts of the machine, and is fixedly connected and assembled with main motor 16, auxiliary motor 5, commutator 19, parts such as rotating shafts of each working belt, metal pallet 14, feeding The hopper 12 is welded with a blade hammering cylinder 33 , an inclined connecting plate 32 , a main motor supporting plate 18 , and a commutator supporting plate 20 .

[0057] Said transmission system is that the main motor 16 is connected with the commutator 19 through a star-shaped elastic coupling 17, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pitch | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Line speed | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com