Implement method of rake convergence drill bit and rake convergence drill bit

An implementation method and drill technology, applied in the field of hole machining tools, can solve the problems of increasing cutting torque, different chip deformation, hindering chip curling and discharge, etc., to reduce cutting force, smooth chip removal, and improve service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to make the purpose, technical solutions and beneficial effects of the present invention more clear, the present invention will be further described in detail below in conjunction with the examples. It should be understood that the specific examples described here are only used to explain the present invention, and are not intended to limit the protection scope of the present invention.

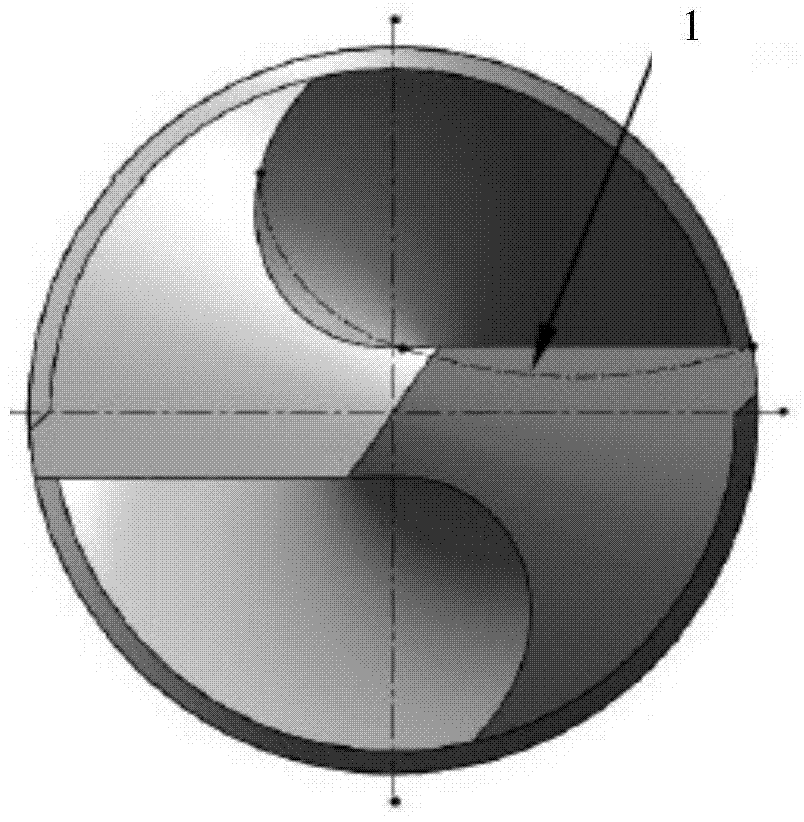

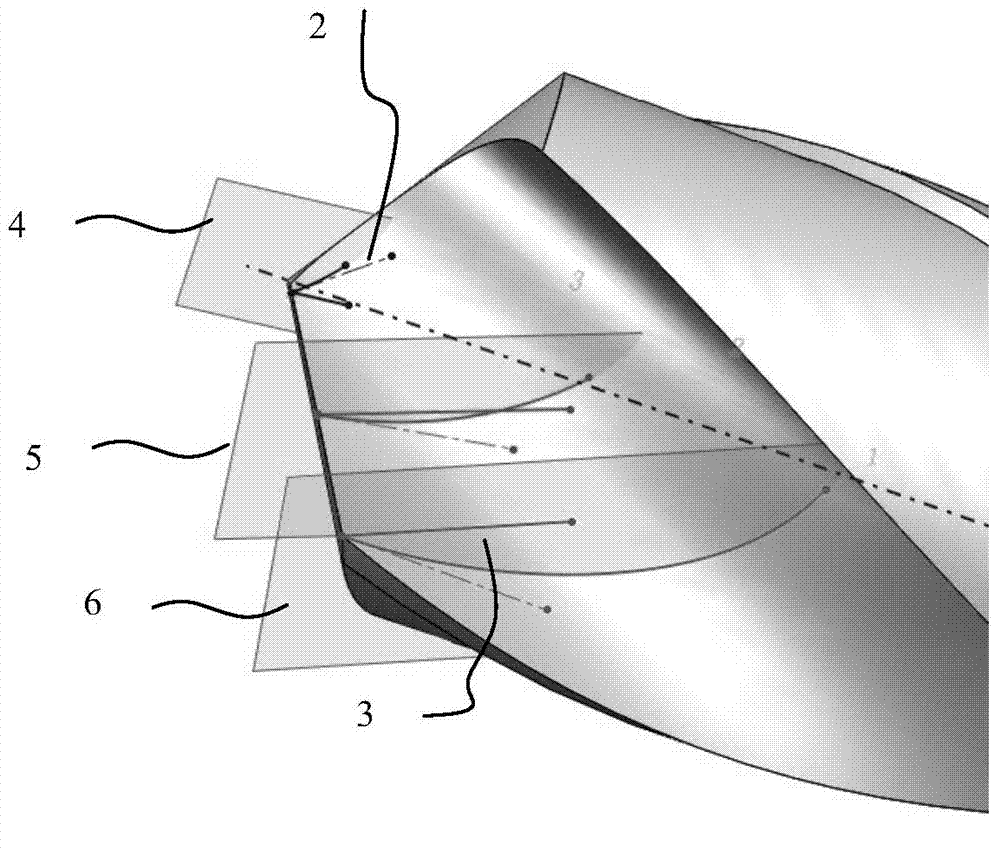

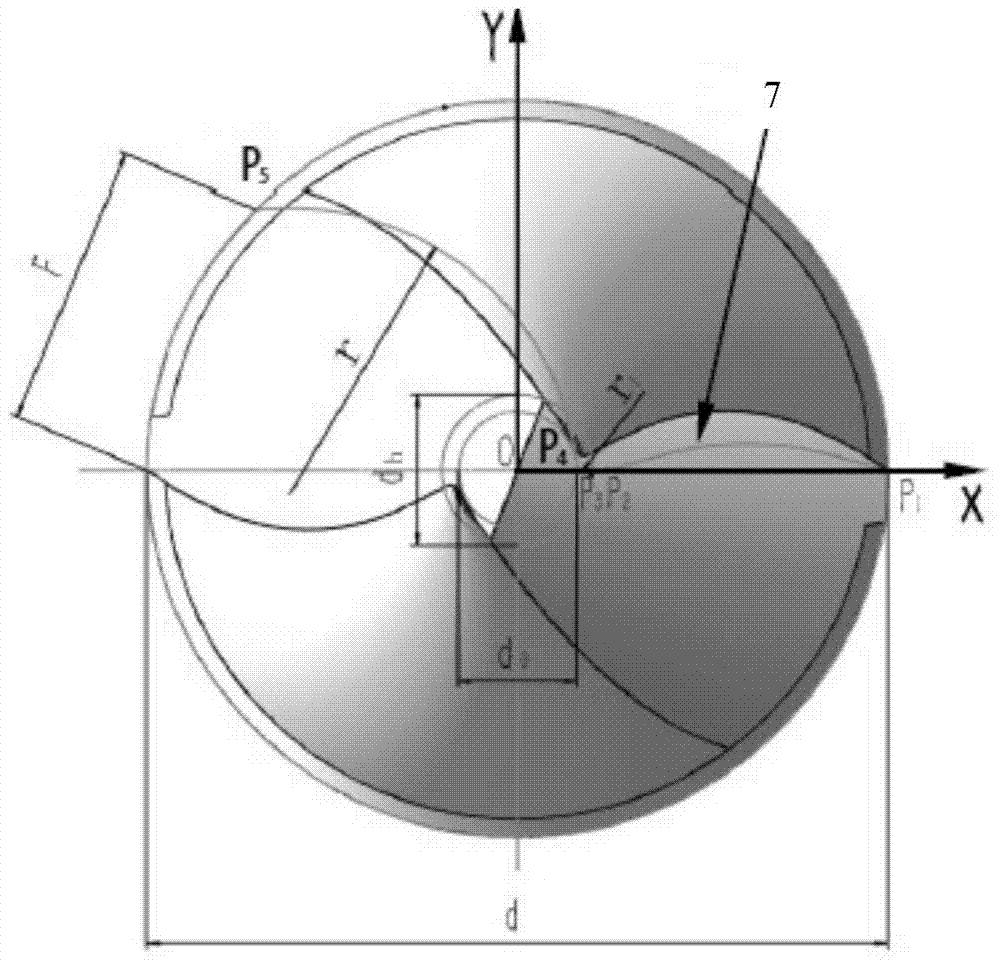

[0013] like image 3 , Figure 4 As shown, in order to achieve the purpose of the present invention, the present invention provides a method for realizing a rake angle converging drill bit, and the method includes the step of designing the end surface sectional curve of the main cutting edge as a sinusoidal curve.

[0014] The invention also provides a rake angle converging drill bit, the end section of the drill bit has a sinusoidal cutting edge section.

[0015] The present invention changes the large rake angle of the main cutting edge of the ordinary drill bit, which is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com