A non-resonant three-dimensional elliptical diamond vibration cutting flexible device

A technology of vibration cutting and flexible devices, which is applied in the field of ultra-precision cutting and processing of complex optical parts of difficult-to-machine materials, can solve the problems of high processing frequency, easy coupling of driving, and increased difficulty of control, etc., and achieves easy high-frequency The processing, the overall structure is simple, the effect of high control precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

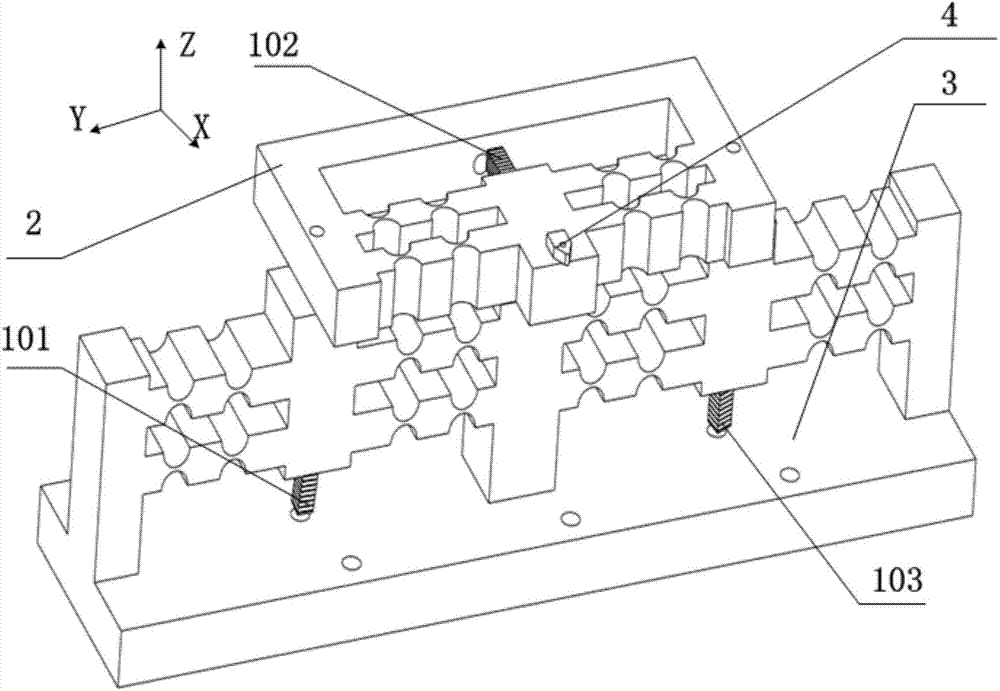

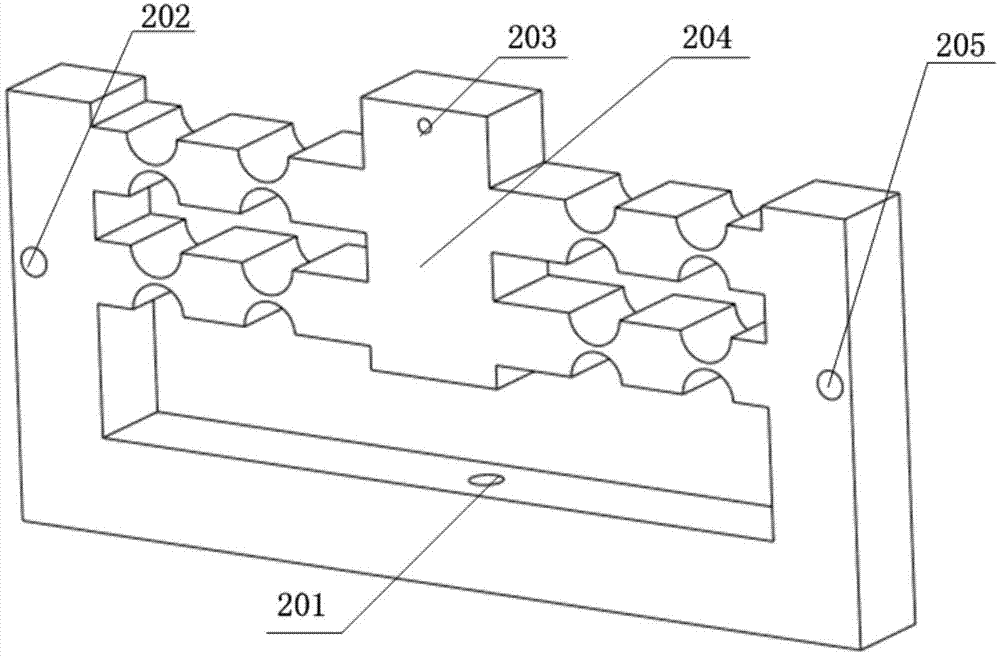

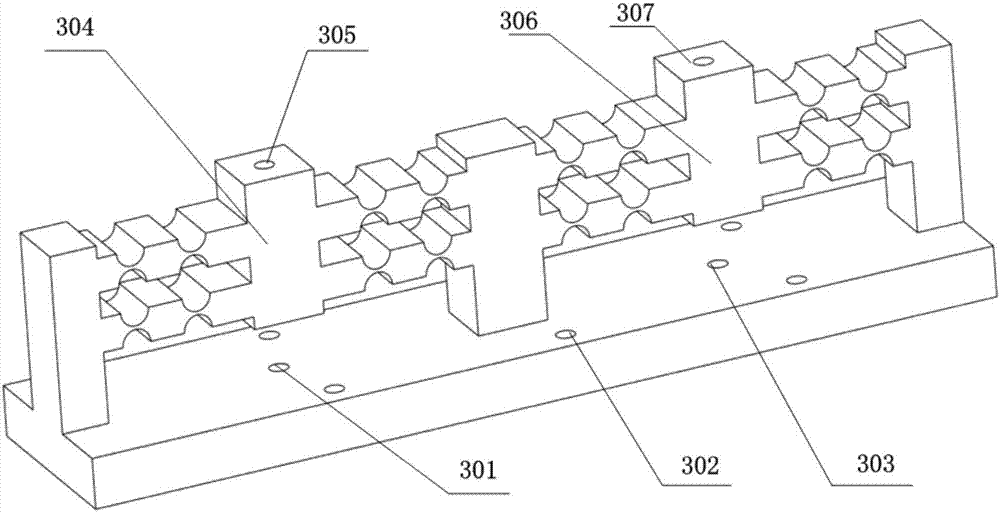

[0030] The upper flexible hinge 2 is vertically assembled with the lower flexible hinge 3, wherein the upper flexible hinge 2 is connected to the lower flexible hinge hole 1 305 and the upper flexible hinge hole 2 205 of the lower flexible hinge 3 by screws respectively through the upper flexible hinge hole 1 202 and the upper flexible hinge hole 2 205. On the lower flexible hinge connecting hole 2 307, the piezoelectric stack 1 101 and the piezoelectric stack 2 103 are preloaded and installed on the lower flexible hinge 3 through the pre-tightened threaded hole 1 301 and the pre-tightened thread 2 303 respectively by bolts. Stack three 102 is preloaded and installed on the upper flexible hinge 2 through the pre-tightened threaded hole three 201 by bolts, and the diamond tool 4 is installed on the threaded hole 203 of the upper flexible hinge 2 by bolts.

[0031] The individual hinges in the upper flexible hinge 2 of the present invention are all straight circular hinges, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com