Bottle blowing machine bed die locking mechanism

A technology of locking mechanism and bottle blowing machine, which is applied in the field of locking mechanism, and can solve the problems affecting the use of bottle blowing machine, the locking effect of the locking mechanism is reduced, and it fails.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

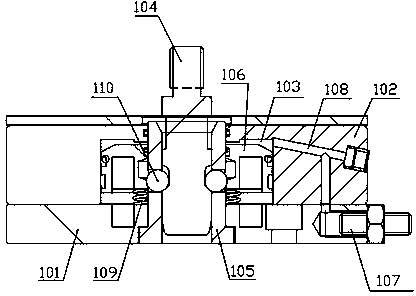

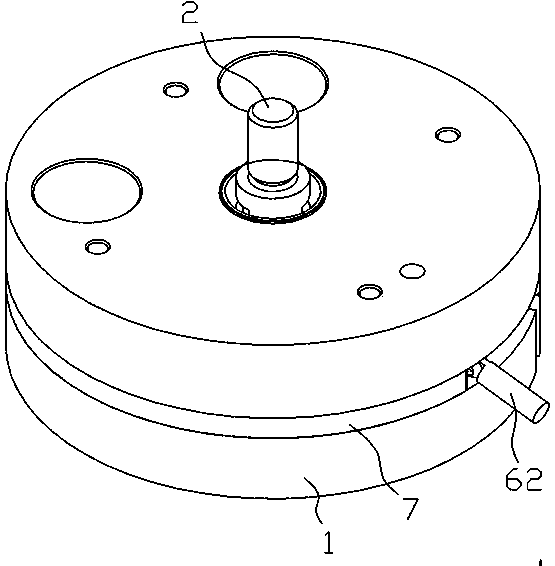

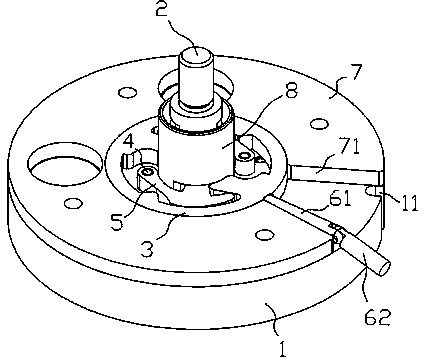

[0012] Such as figure 2 -9 shown.

[0013] The bottom mold locking mechanism of the bottle blowing machine according to the present invention includes a bottom plate 1 fixed on the frame of the bottle blowing machine and a bottom mold pull stud 2 connected to the bottom mold, and a positioning groove 21 is opened on the outer wall of the bottom mold pull stud 2 , the bottom plate 1 is equipped with a rotating block 3 with a cam curve, and there is a locking block 5 for locking the bottom mold pull stud 2 that rotates around the positioning pin 4 fixed on the bottom plate 1, and the locking block 5 is provided with a snap-in positioning groove 21 and fix the locking head 51. When the rotating block 3 rotates, the cam curve on it drives the locking block 5 to rotate so that the locking head 51 snaps into or exits the positioning groove 21, and there is also a drive to drive the rotating block 3 to rotate. device.

[0014] The bottom mold locking mechanism of the bottle blowin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com