Double-chamber three-dimensional pouring bioreactor system

A bioreactor, three-dimensional technology, applied in the direction of biochemical instruments, biochemical equipment and methods, methods of supporting/immobilizing microorganisms, etc., can solve the problems of large amount of induced culture factors, low yield, difficult to obtain, etc., to achieve effective utilization The effect of efficiency, cost reduction and consumption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

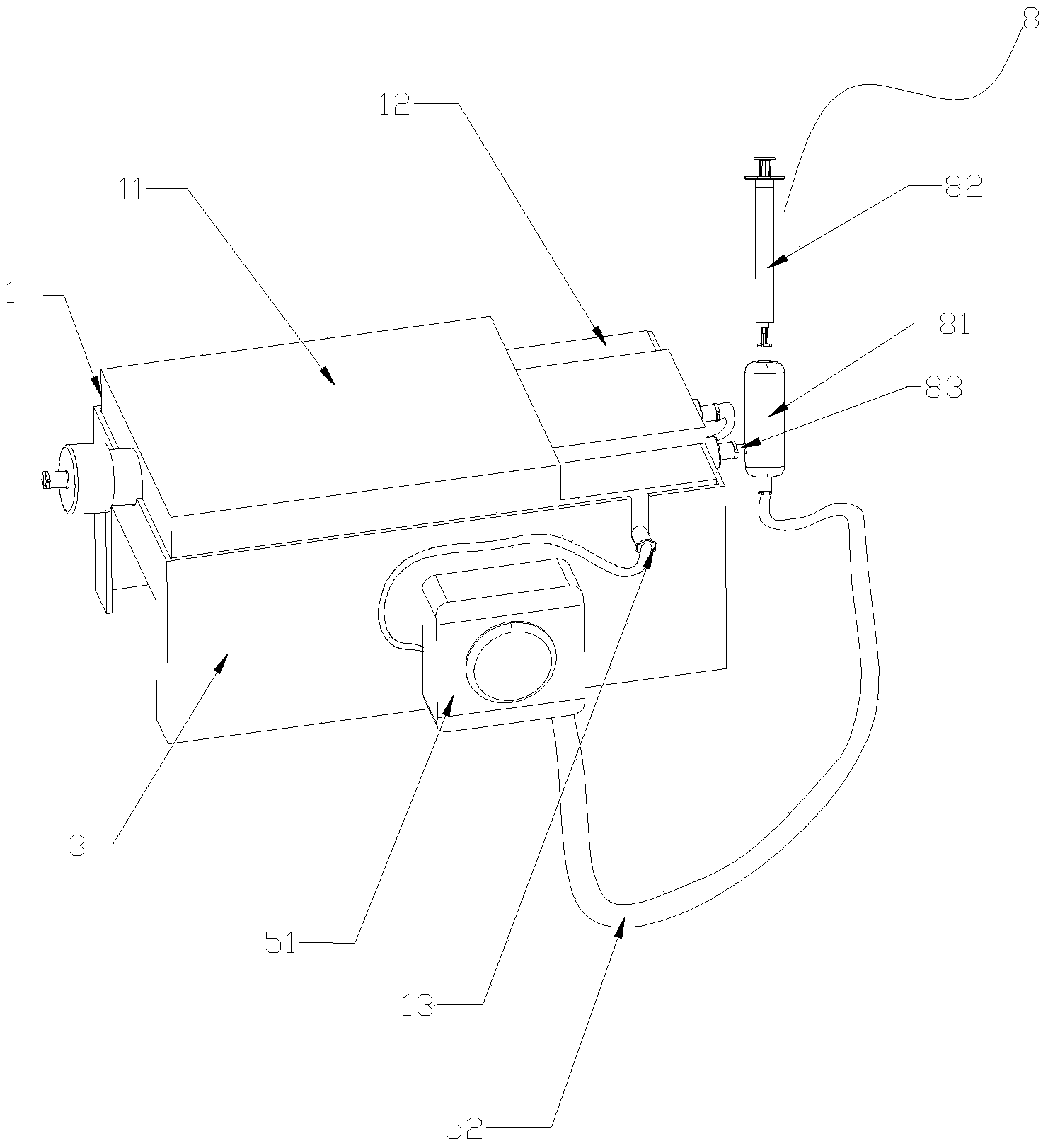

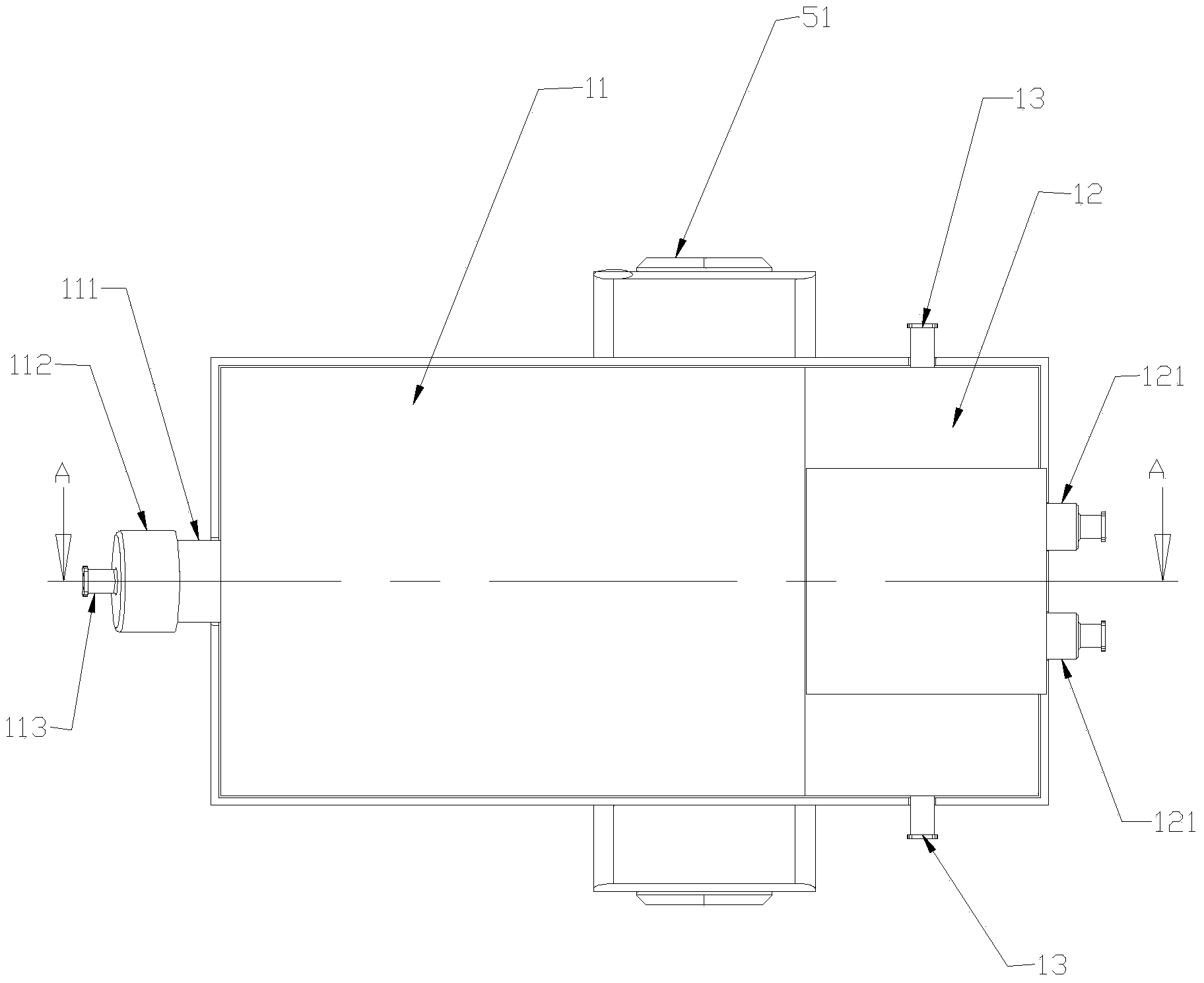

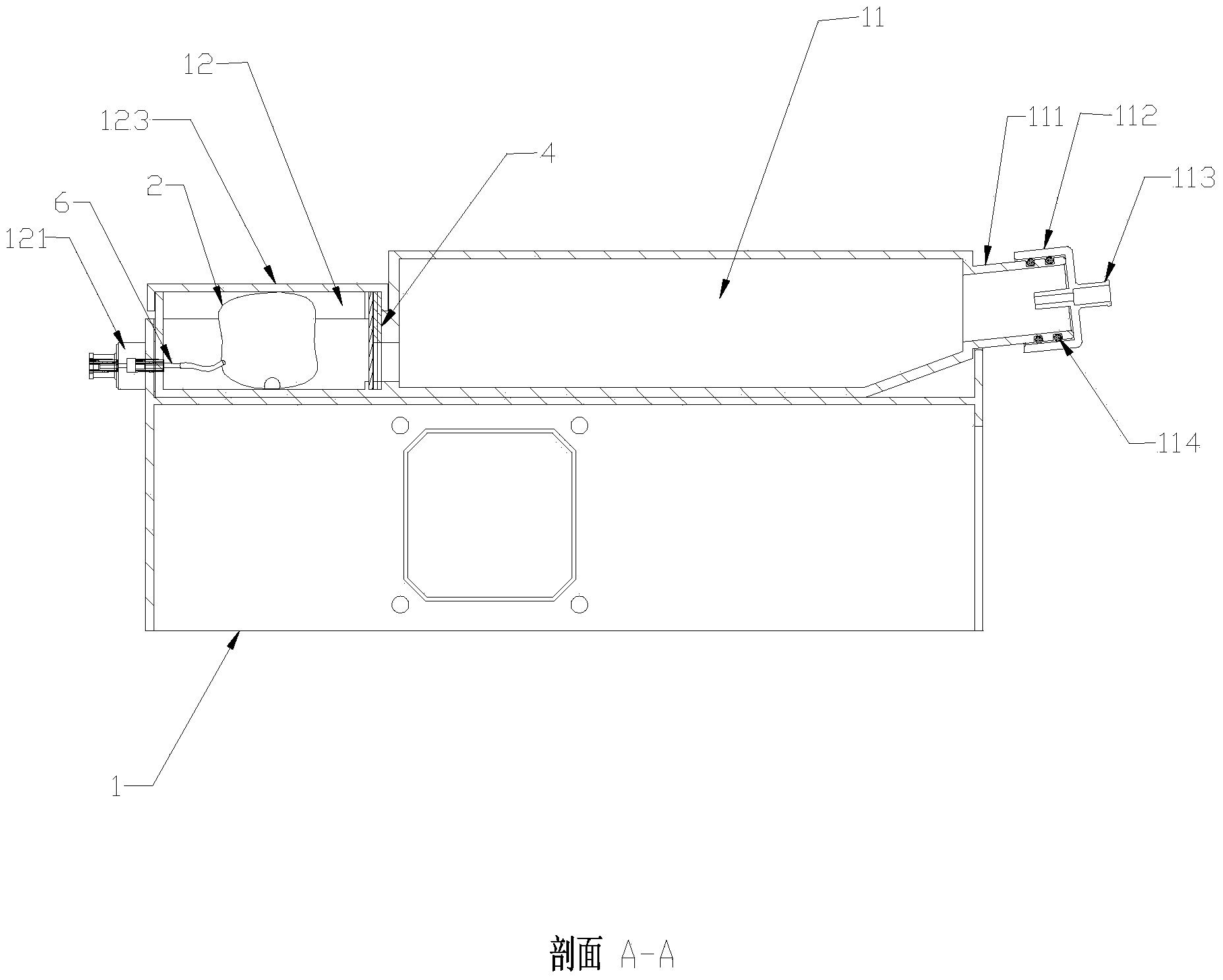

[0037] Specific embodiments of the present invention such as Figure 1-9 Shown is a two-chamber three-dimensional perfusion bioreactor system, including a bioreactor 1, a three-dimensional support 2 is arranged in the bioreactor 1, a perfusion device is connected to the bioreactor 1, the bioreactor includes a base 3, and a common nutrient culture solution is provided. The filled first chamber 11, and the second chamber 12 filled with inducible culture factors, the first chamber 11 and the second chamber 12 are located on the base 3, and the base 3 acts as a support and the power of the fixed circulation perfusion device The role of the source of the peristaltic pump; between the first chamber 11 and the second chamber 12, there is a dialysis membrane assembly 4 that can pass through the components whose molecular weight is smaller than that of the induced cytokine in the induced culture factor, and the three-dimensional support 2 is located in the second chamber 12 in. The de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com