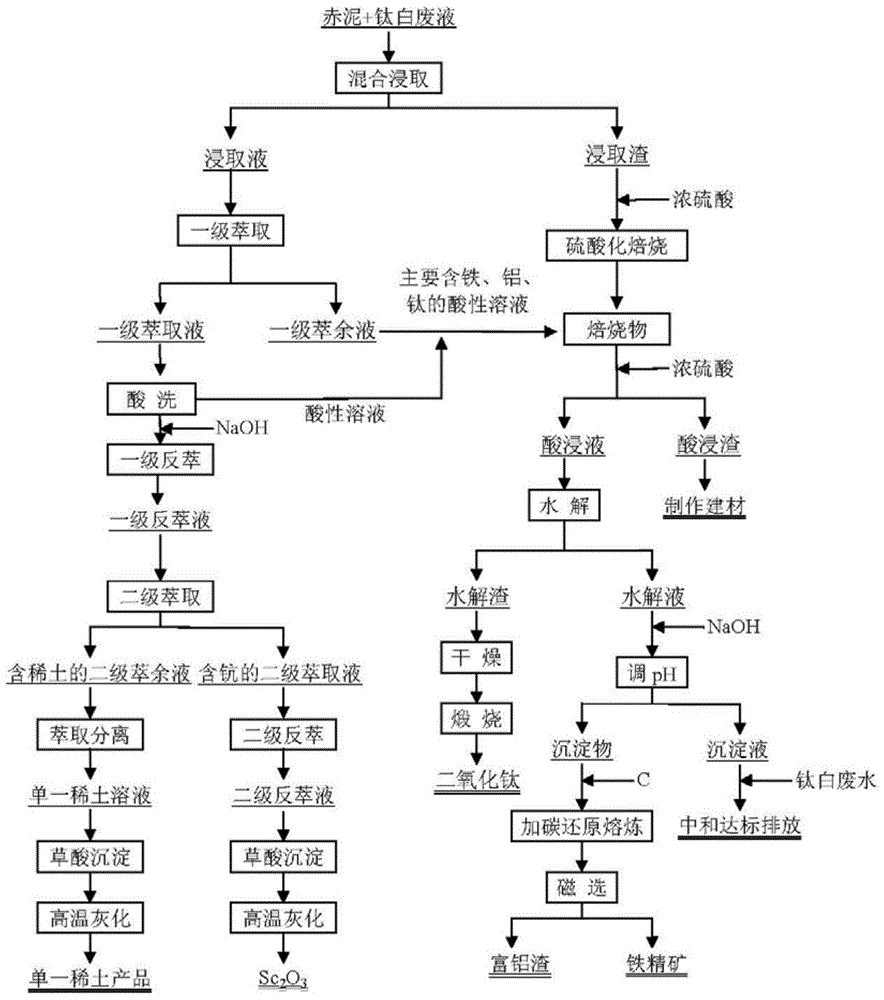

Method for comprehensive recovery and treatment of red mud waste residue and titanium dioxide waste liquid

A titanium dioxide waste liquid, recycling and treatment technology, applied in the direction of improving process efficiency, etc., can solve the problems of multiple devices, occupancy, single, etc., and achieve the effect of large quantity, simple process flow, and wide sources of waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0045] According to a typical implementation of the present invention, the calcination process includes: keeping the dried hydrolysis slag at 300°C-400°C for 40-60 minutes, then keeping it at 600-700°C for 80-120 minutes, and finally heating it at 850°C ℃~950℃ for 40~60 minutes. The above-mentioned calcination method is conducive to the stable formation of titanium dioxide, can recover the valuable element titanium to the maximum extent, and has the advantages of high product recovery rate and purity.

[0046] Preferably, the process of preparing aluminum-rich slag and iron concentrate in step S33 includes: adjusting the pH of the hydrolyzate to 9-11 to obtain a precipitate and a precipitate; Reductive smelting to obtain a smelted mixture; and performing magnetic separation on the smelted mixture at a magnetic separation intensity of 0.7-0.9T to obtain aluminum-rich slag and iron concentrate. Among them, the precipitate is mainly iron hydroxide precipitation and aluminum hydr...

Embodiment 1

[0049] The valuable elements rare earth, scandium, titanium, iron and aluminum are comprehensively recovered from red mud waste residue and titanium dioxide waste liquid through the following steps. Among them, the main component content of red mud waste residue: RE x o y 0.10%, Sc 2 o 3 0.01%, TiO 2 4.88%, Fe 2 o 3 37.37%, Al 2 o 3 5.69%; main component content of titanium dioxide waste liquid: RE x o y 3.7mg / L, Sc 2 o 3 9.4mg / L, TiO 2 2.02g / L, Fe 2 o 3 31.33g / L, Al 2 o 3 1.00g / L, H 2 SO 4 2.70mol / L.

[0050] 1) Take 100g of red mud waste residue and 500ml of titanium dioxide waste liquid according to the liquid-solid ratio (volume:mass) 5:1 and mix and leaching at 90°C for 2 hours to obtain 590ml of leaching solution. The mass of each element in the leaching solution The percentage concentrations are as follows: RE x oy 0.15g / L, Sc 2 o 3 22.85mg / L, Fe 2 o 3 78.23g / L, Al 2 o 3 8.58g / L, the calculated leaching rate of rare earth elements in red mud wa...

Embodiment 2

[0061] The selected red mud waste slag and titanium dioxide waste liquid are the same as those in Example 1, and their chemical components are the same as above.

[0062] 1) Mix 100g of red mud waste residue and 400ml of titanium dioxide waste liquid at a liquid-to-solid ratio of 4:1, and then leaching at 50°C for 1 hour to obtain 430ml of leaching solution, in which the mass percentage concentration of each element in the leaching solution is as follows :RE x o y 0.17g / L, Sc 2 o 3 24.37mg / L, Fe 2 o 3 90.00g / L, Al 2 o 3 10.17g / L, the calculated leaching rate of rare earth elements in red mud residue is 71.57%, leaching rate of scandium element is 67.22%, leaching rate of iron element is 70.01%, and leaching rate of aluminum element is 69.81%.

[0063] 2) Take 400ml of the leaching solution, and use P204 with a volume percentage concentration of 10% for primary extraction. During the extraction process, ethanol is added as a demulsifier (the volume of ethanol is 10% of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com