Angle self-adaptation and lifting type construction platform

A construction platform and self-adaptive technology, applied in the direction of building structure support, building structure support, building structure support scaffolding, etc., to achieve the effect of high structural adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

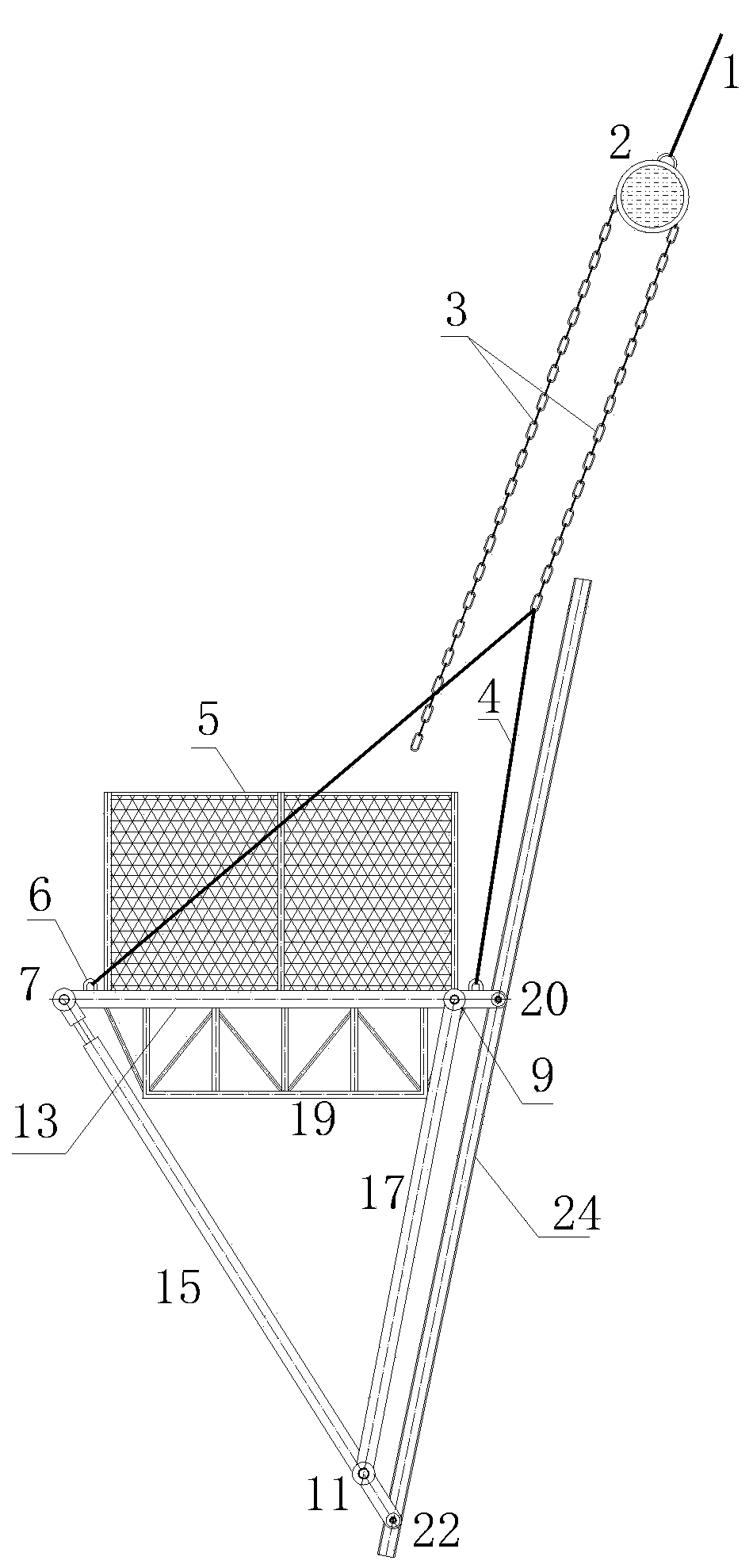

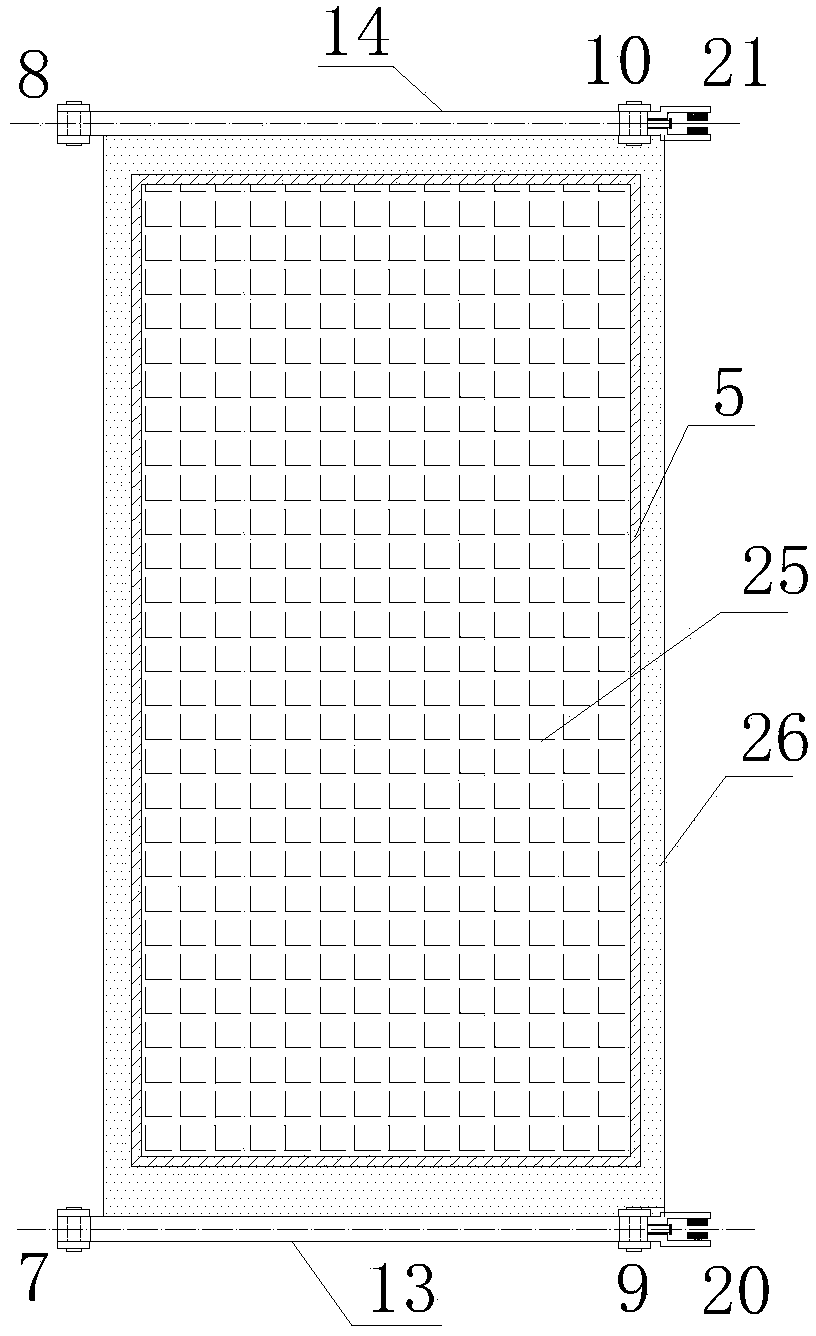

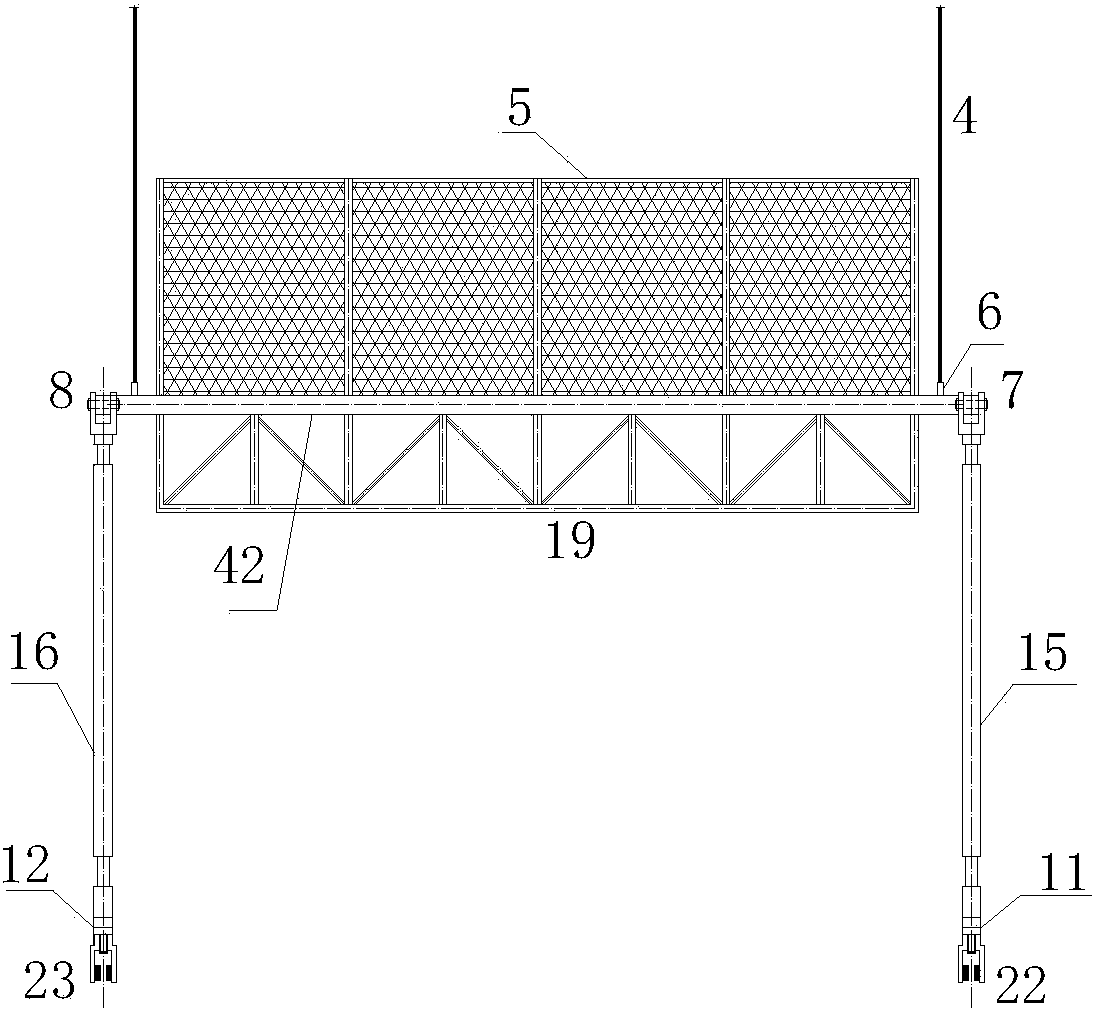

[0026] Attached below Figure 1 to Figure 6 Specific embodiments of the present invention will be described in detail.

[0027] The specific implementation steps are as follows:

[0028] Step 1: Install the lifting equipment 2, and lay two rows of double-layer I-beam stacked rail slides along the formwork at a certain interval to the predetermined height, and reserve a section of trackless area at the bottom.

[0029] Step 2: On the slideways on both sides, slide and hang the front-end card groove rollers of the right upper pole 13, the right outer pole 15, the left upper pole 14, and the right outer pole 18 respectively from the trackless area Into the section steel slideway 24 of double-layer I-beam stacked rails, according to the platform structure requirements, the upper and lower layers, left and right rows of support rods are arranged at a certain distance along the section steel slideway 24, and are passed through the retractable friction rods in the groove rollers. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com