Tungsten-nickel-iron alloy and high-strength steel diffusion welding method for intermediate layer prepared through material reduction

A tungsten-nickel-iron alloy and diffusion welding technology, which is applied in welding equipment, manufacturing tools, metal processing equipment, etc., can solve the problems of poor adaptability of the middle layer structure, easy formation of brittle intermetallic compounds, and large joint welding thermal stress, etc., to achieve relaxation The effects of welding thermal stress, improving structural adaptability, and ensuring strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

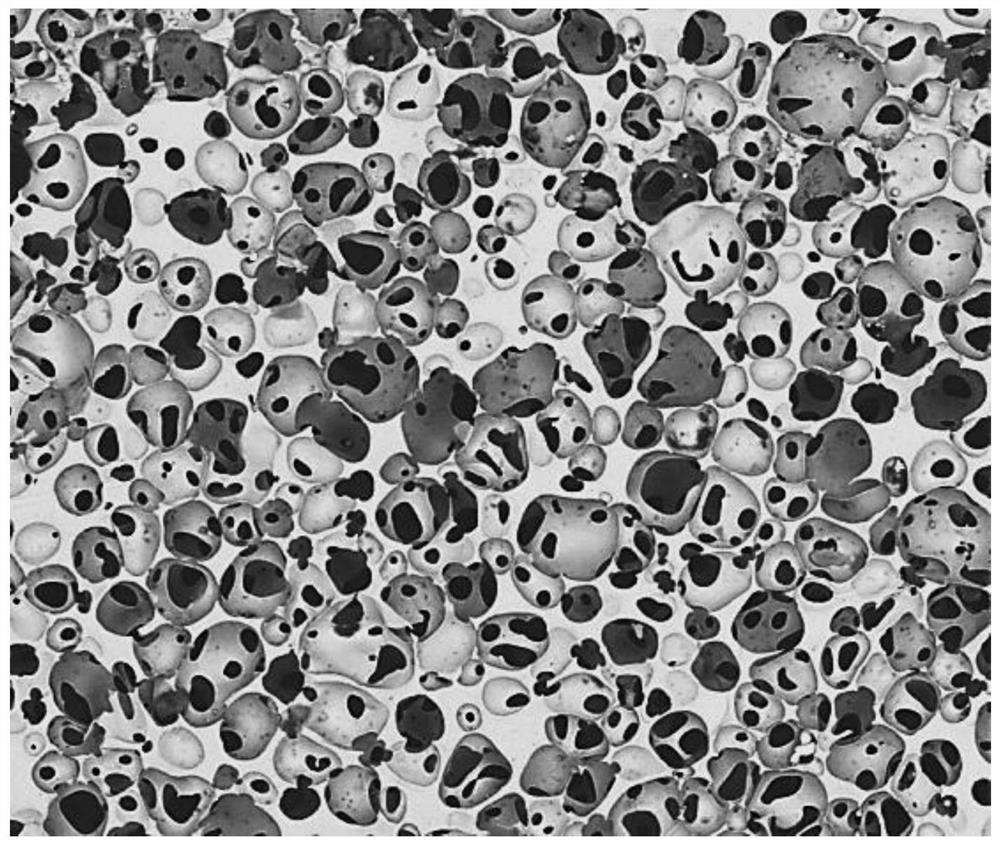

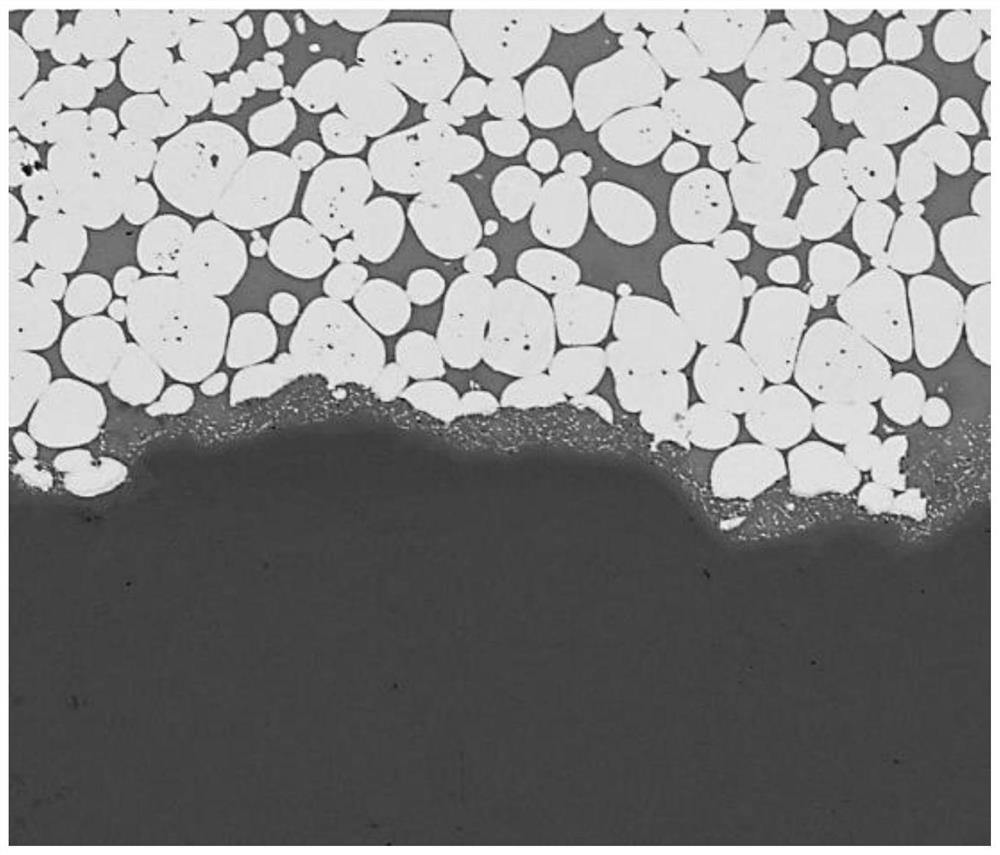

Image

Examples

Embodiment 1

[0021] This embodiment is a welding method of tungsten-nickel-iron alloy and high-strength steel. The tungsten-nickel-iron alloy involved is 90WNiFe alloy, cut into Φ36×20mm 3 The high-strength steel involved is 60CrMnMo steel, cut into Φ36×20mm 3 of the cylinder.

[0022] The specific process of this embodiment includes the following steps:

[0023] Step 1: After polishing the surfaces of 90WNiFe alloy and 60CrMnMo high-strength steel with 150-mesh, 400-mesh, 600-mesh, 800-mesh, and 1000-mesh sandpaper in turn, use W0.5 diamond polishing paste for polishing to ensure that the surfaces to be welded are flat and free of oxidation membrane.

[0024] Step 2, put the polished 90WNiFe alloy and 60CrMnMo high-strength steel in alcohol for 15 minutes with ultrasonic cleaning; put the cleaned 90WNiFe alloy and 60CrMnMo high-strength steel into a vacuum drying box, set the drying temperature to 50°C and the drying time For 20min, dry for use.

[0025] Step 3, take an appropriate a...

Embodiment 2

[0031] This embodiment is a welding method of tungsten-nickel-iron alloy and high-strength steel. The tungsten-nickel-iron alloy involved is 93WNiFe alloy, cut into Φ36×20mm 3 The high-strength steel involved is 40Cr, cut into Φ36×20mm 3 of the cylinder.

[0032] The specific process of this embodiment includes the following steps:

[0033] Step 1. After polishing the surfaces of 93WNiFe alloy and 40Cr high-strength steel with 150-mesh, 400-mesh, 600-mesh, 800-mesh, and 1000-mesh sandpaper in turn, use W0.5 diamond polishing paste for polishing to ensure that the surfaces to be welded are flat and free of oxidation membrane.

[0034] Step 2, put the polished 93WNiFe alloy and 40Cr high-strength steel into alcohol and ultrasonically clean for 15 minutes. Put the cleaned 93WNiFe alloy and 40Cr high-strength steel into a vacuum drying oven, set the drying temperature to 50 °C and the drying time to 20 min, and dry for use.

[0035] Step 3, take an appropriate amount of NaOH,...

Embodiment 3

[0041] This embodiment is a welding method of tungsten-nickel-iron alloy and high-strength steel. The tungsten-nickel-iron alloy involved is 95WNiFe alloy, cut into Φ36×20mm 3 The high-strength steel involved is 42CrMoV, cut into Φ36×20mm 3 of the cylinder.

[0042] The specific process of this embodiment includes the following steps:

[0043] Step 1, polish the surfaces of 95WNiFe alloy and 42CrMoV high-strength steel with 150-mesh, 400-mesh, 600-mesh, 800-mesh, and 1000-mesh sandpaper in turn, and then use W0.5 diamond polishing paste for polishing to ensure that the surfaces to be welded are flat and free of oxidation membrane.

[0044] Step 2, put the polished 95WNiFe alloy and 42CrMoV high-strength steel in alcohol for 15 minutes with ultrasonic cleaning; put the cleaned 95WNiFe alloy and 42CrMoV high-strength steel into a vacuum drying box, set the drying temperature to 50°C and the drying time For 20min, dry for use.

[0045] Step 3, take an appropriate amount of N...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com