High temperature crude biomass gas burner

A biomass gas and burner technology, applied in the direction of gas fuel burners, burners, combustion methods, etc., can solve problems such as insufficient output, insufficient combustion, poor stability, etc., to increase fuel adaptability and ensure that active ingredients are burned out Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Selected embodiments of the present invention are now explained with reference to the accompanying drawings. The following descriptions of the embodiments of the present invention disclosed by those skilled in the art are only exemplary and not intended to limit the solutions of the present invention.

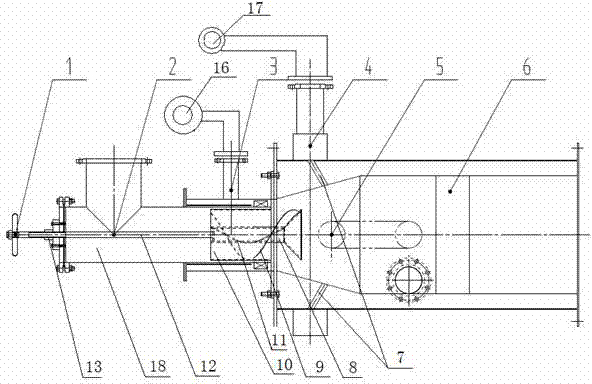

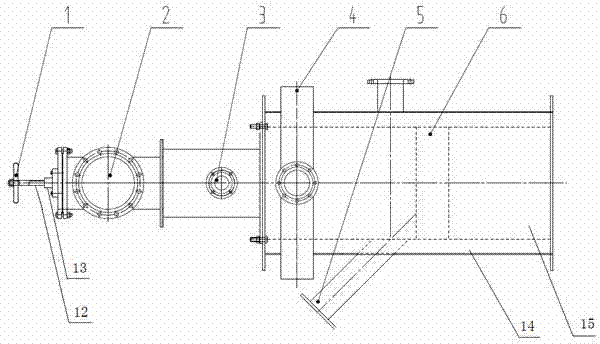

[0022] A high-temperature crude biomass gas burner includes a combustion host 2, a gas channel 18, a turbulent flow regulating mechanism, a primary air distribution mechanism, a high-temperature heat storage combustion chamber, and a secondary air distribution mechanism.

[0023] The gas channel 18 has a gas inlet section and a gas outlet section. The gas channel 18 is connected to the combustion host 2 and the high-temperature regenerative combustion chamber. The combustion host 2 is connected to the gas inlet section, and the high-temperature regenerative combustion chamber is connected to the gas outlet section; Including a turbulence device and an adjustment device, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com