Optical fiber sensor combination for monitoring corrosion of reinforced concrete

An optical fiber sensor, reinforced concrete technology, applied in the direction of weather resistance/light resistance/corrosion resistance, instruments, measuring devices, etc., can solve the problem of inability to meet the requirements of rough construction of concrete structures, complicated production process of corrosion sensitive film, and inconsistent thickness of corrosion sensitive film. Uniformity and other problems to achieve the effect of avoiding the change of corrosion form, avoiding galvanic corrosion and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

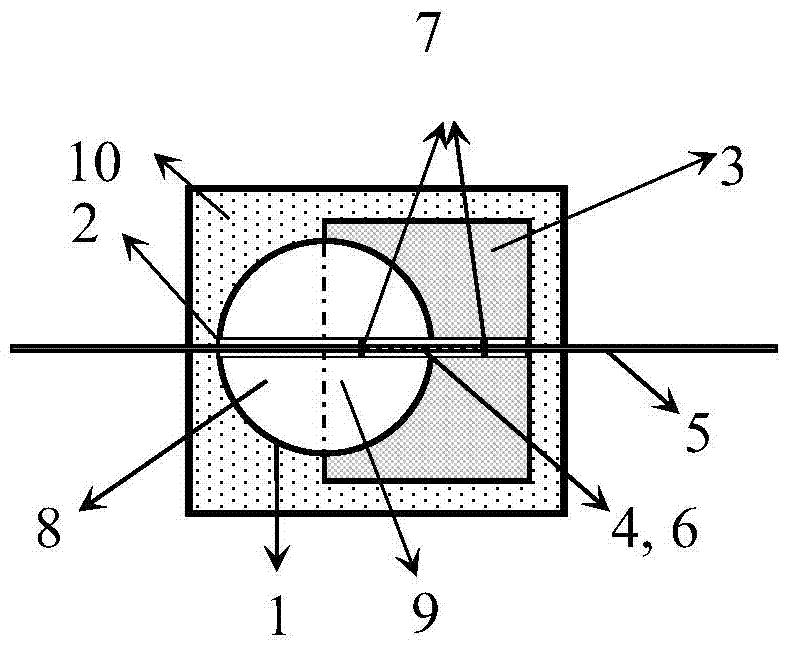

[0037] Fiber optic sensor as shown

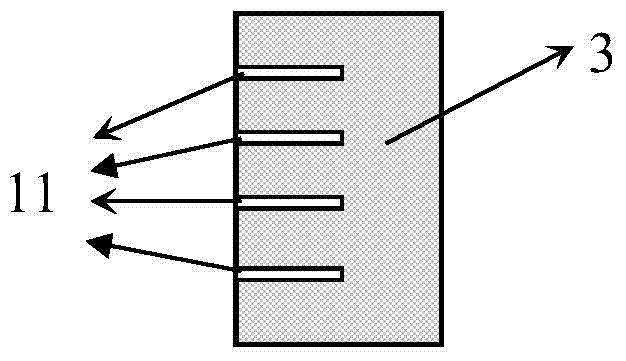

[0038] The fiber optic sensor consists of the following components: (1) Reinforcement element; (2) Fixing hole; (3) Reinforced fiberglass support; (4) Fiber Bragg grating; (5) Connecting optical fiber; (6) Sheath tube; (7) ) Silica gel sheet; (8) Coated area of steel bar components; (9) Uncoated area of steel bar components; (10) Mortar shell; (11) Penetrating gaps.

[0039] The structural characteristics of the optical fiber sensor are as follows: the steel bar element 1 is a round steel with the same diameter as the steel bar used in the project, its length is π times the radius of the round steel, and the circular sections at both ends are coated with paint. A through fixing hole 2 is opened at the center of the steel bar for fixing the fiber Bragg grating 4 and its connecting optical fiber 5 . The inner diameter of the reinforced fiberglass reinforced plastic support 3 coincides with the outer diameter of the reinforcement element,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com