A kind of assembly method of button type lithium ion battery

A technology of lithium-ion batteries and assembly methods, which is applied in the manufacture of secondary batteries, non-aqueous electrolyte batteries, electrolyte batteries, etc., can solve the problems of failure to realize the positive plate, achieve improved consistency, improved battery performance, and reduced material consumption Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] A method for assembling a button lithium ion battery, comprising the steps of:

[0015] a. Place the positive electrode sheet at the center of the positive electrode case, and then use a resistance welding machine to weld the edge of the positive electrode sheet to the positive electrode battery case with one welding point.

[0016] b. Put it into the glove box → put the welded positive electrode shell flat → add the diaphragm → add the electrolyte → add the negative electrode sheet → add foam nickel → add the negative electrode shell → seal it → put it in a bag → take out the glove box.

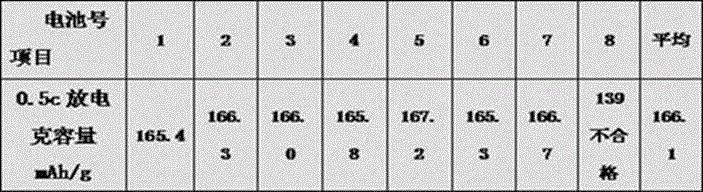

[0017] Check the pass rate, capacity and consistency by measuring the electrochemical performance of the battery separately. Complete the assembly of 8 batteries according to the method of this embodiment, and test the batteries, and record the gram capacity data of the batteries as follows:

[0018]

Embodiment 2

[0020] The steps of this embodiment are basically the same as those of Embodiment 1, except that the welding points in step a are two corresponding points.

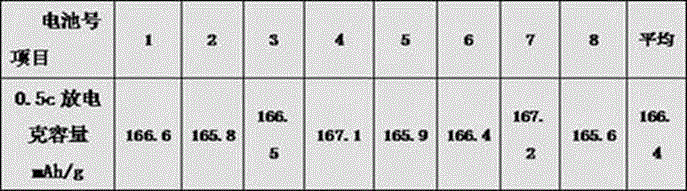

[0021] Complete the assembly of 8 batteries according to the method of this embodiment, and test the batteries, and record the gram capacity data of the batteries as follows:

[0022]

Embodiment 3

[0024] The steps of this embodiment are basically the same as those of the previous two embodiments, except that the welding points in step a are three points evenly distributed.

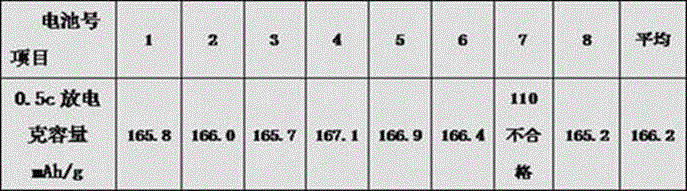

[0025] Complete the assembly of 8 batteries according to the method of this embodiment, and test the batteries, and record the gram capacity data of the batteries as follows:

[0026]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com