Inverter welding machine with PFC (Positive Feedback Circuit) function

A technology of inverter welding machine and rectifier circuit, which is applied in the direction of output power conversion device, conversion of DC power input to DC power output, energy industry, etc., which can solve the problems of large power grid damage and low power utilization rate, and achieve energy saving energy, avoid harmonic interference, and improve the effect of power utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Embodiments of the present invention are described in detail below:

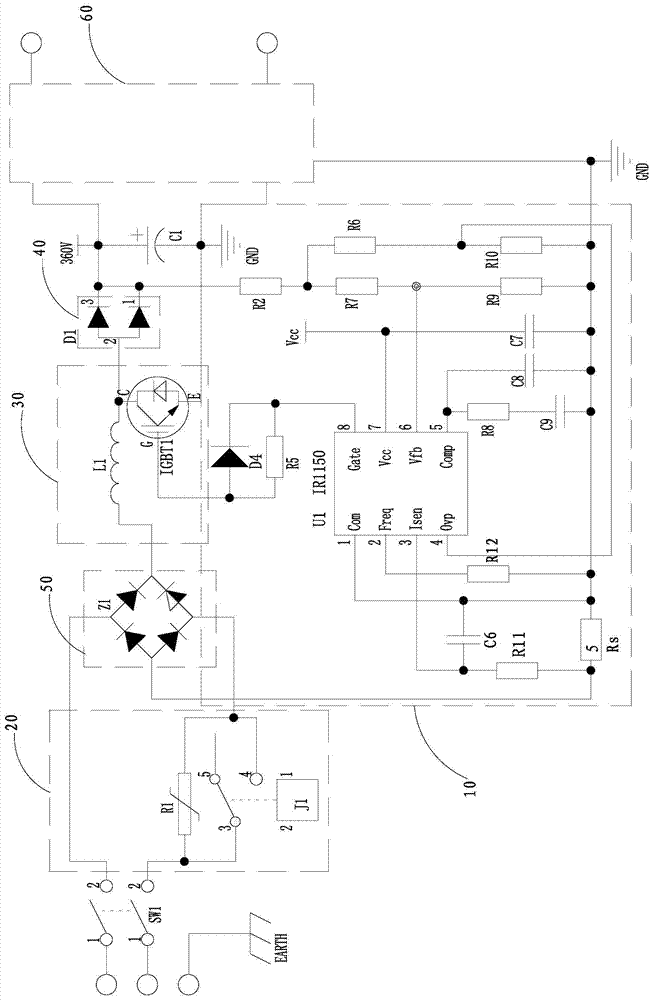

[0018] Such as figure 1 As shown, an inverter welding machine with PFC function includes an AC input switch SW1, a rectifier circuit 50, a boost circuit 30, a fast rectifier circuit 40, a filter circuit and an inverter circuit 60 connected in sequence, and the boost circuit 30 includes an inductor L and an insulated gate bipolar transistor IGBT, one end of the inductor L is connected to the positive output end of the rectifier circuit 50, the other end of the inductor L is connected to the collector of the IGBT, and the emitter of the IGBT is connected to the The negative output terminal of the rectification circuit 50 is connected, and a sampling resistor R is connected between the emitter of the IGBT and the negative output terminal of the rectification circuit 50. s , the sampling resistor R s A PFC control circuit is connected in parallel at both ends, and the PFC control circuit 10 is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com