flat speaker

A flat-panel loudspeaker, plane technology, applied in plane diaphragm, frequency/direction characteristic device, sensor, etc., to achieve the effect of ultra-thin, remarkable sound output, and control the deterioration of sound quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

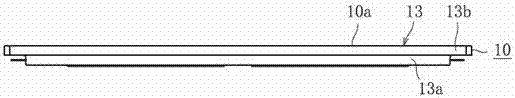

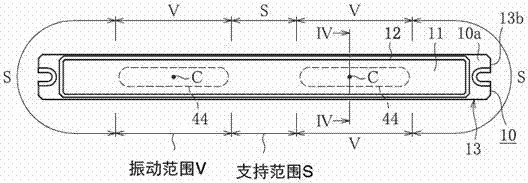

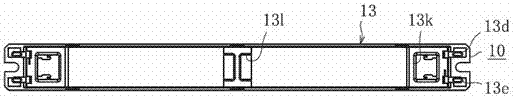

[0021] A flat-panel speaker, including a support frame, is characterized in that: at least one sound unit is arranged along the axial direction of the support frame, and each sound unit consists of a planar vibrating membrane that vibrates and emits sound waves and a frame installed along the periphery of the planar vibrating film and responds to the sound. Vibration of the signal action The driving device of the planar vibrating membrane is composed of at least one pair of non-contact spaces on the side of the ditch part opened on the support frame, and the non-contact space is the ditch opened on the support frame Along a cut corner on the outer side of the bottom surface of the part, the frame installed along the periphery of the planar vibrating membrane is bonded to the grooved part provided on the supporting frame. It is characterized in that: the non-contact spaces on both sides of the ditch part opened on the support frame are symmetrically distributed according to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com