Boot band

A technology of clamps and sleeves, applied in applications, couplings, connecting components, etc., can solve the problems of reduced rigidity, insufficient bending load resistance, and reduced bending load.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach )

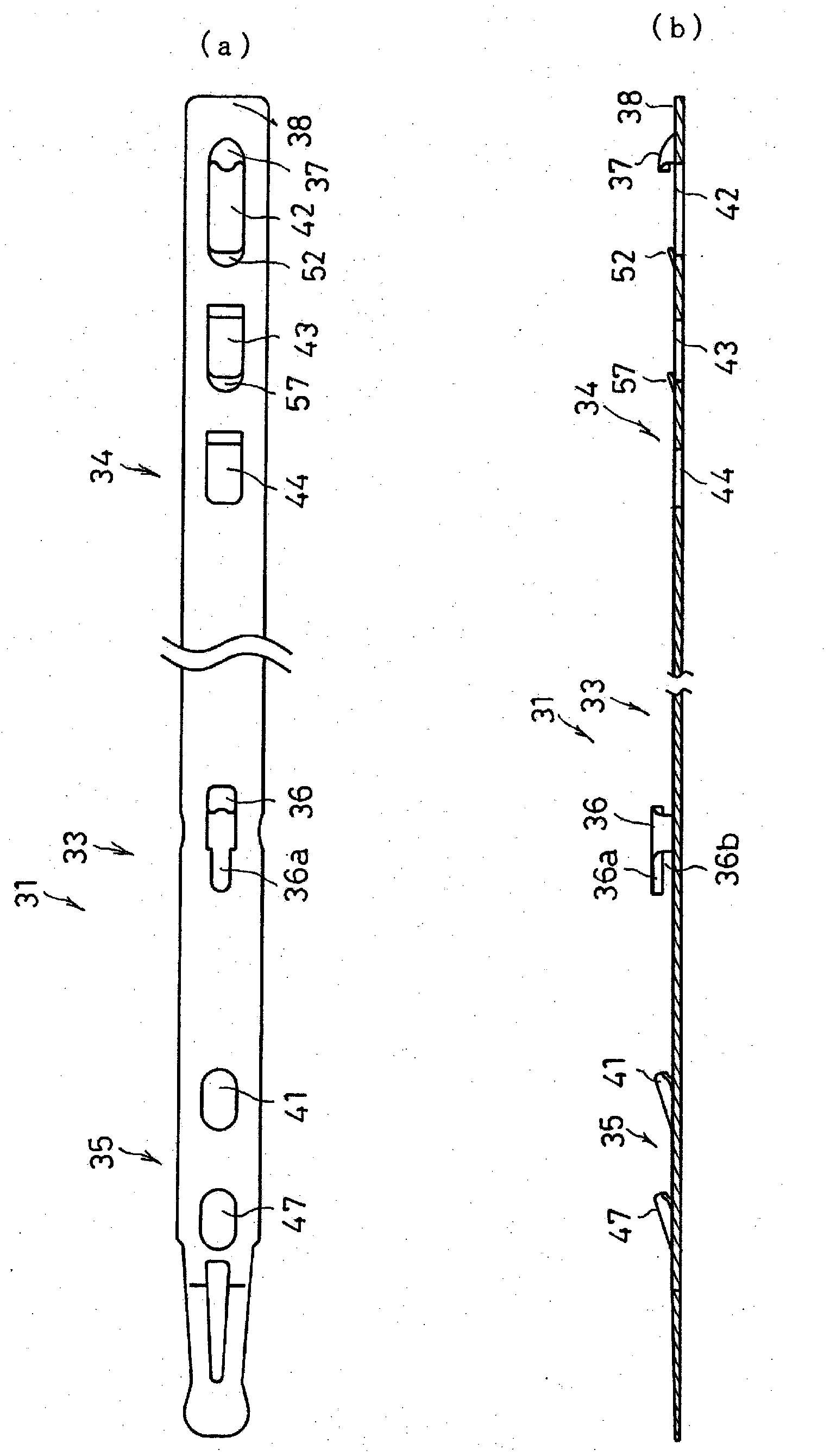

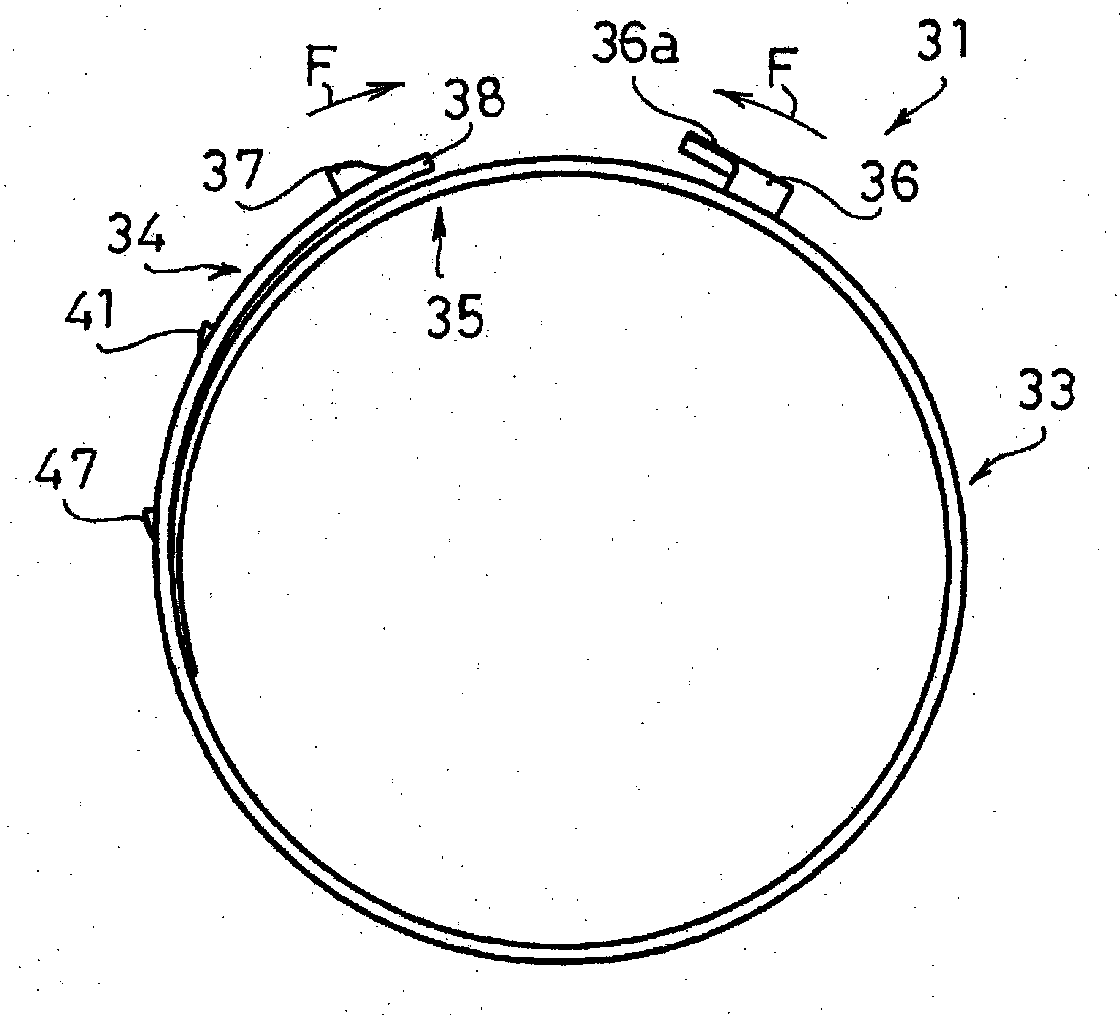

[0040] Figure 1 to Figure 7 The first embodiment of the present invention is shown. Such as Figure 1 ~ Figure 3 As shown, the sleeve collar 31 is formed from a collar body 33 constructed of sheet metal.

[0041] The clip main body 33 is formed into a strip shape by punching a thin metal plate, and is used for fastening fastened members (not shown) such as sleeves in a state of being wound from the strip shape into a ring shape. The ring-shaped clamp body 33 is formed with overlapping outer overlapping portions 34 and inner overlapping portions 35, and these overlapping portions 34, 35 pass through in the diameter-reducing direction ( figure 2 In the direction of the middle arrow F) pull each other (引き店せる) to fasten the fastened parts.

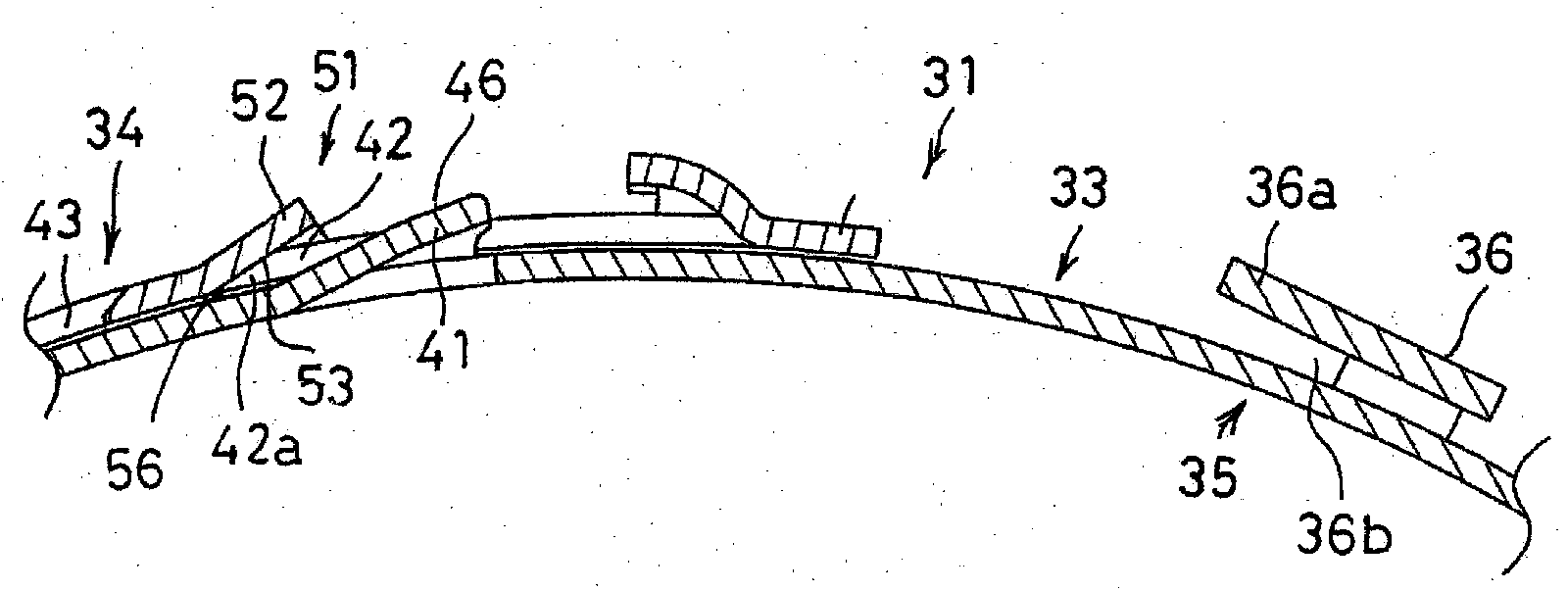

[0042] On the front end side of the outer overlapping portion 34 ( figure 1 The right end side in the center) is formed with a first tool claw 37 standing radially outward. A flat terminal portion 38 is formed on a free end at the fron...

no. 2 approach )

[0068] Figure 8 and Figure 9 A sleeve clip 31A according to a second embodiment of the present invention is shown. The difference from the first embodiment is that in the sleeve clip 31A, the guide unit 51 is the inner surface 55 of the rear end portion 42a opposite to the engaging claw 41 in the front end side engaging hole 42, and the inclined portion 53 is provided on the The inner surface 55 and other components are the same as those of the first embodiment.

[0069] In the ferrule clip 31A of this embodiment, with respect to the engaging claws 41 of the inner overlapping portion 35 , an engaging hole 42 on the front end side and a subsequent engaging hole 43 on the rear side are formed along the longitudinal direction of the outer overlapping portion 34 . The inclined portion 53 of the inner surface 55 of the front end engaging hole 42 is formed by press molding, coining, etc. so as to incline in the same direction as the rear surface 46 of the engaging claw 41 along ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com